Emblic deep processing method and emblic stoning device

A processing method and a technology for Emilia, which are applied in the field of a deep-processing method and a denucleating device for Emblica, can solve the problems of inconvenience, high gallic acid content, low gallic acid content, etc., and achieve automatic denucleation. Effects of nuclear manipulation, high gallic acid content, and high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

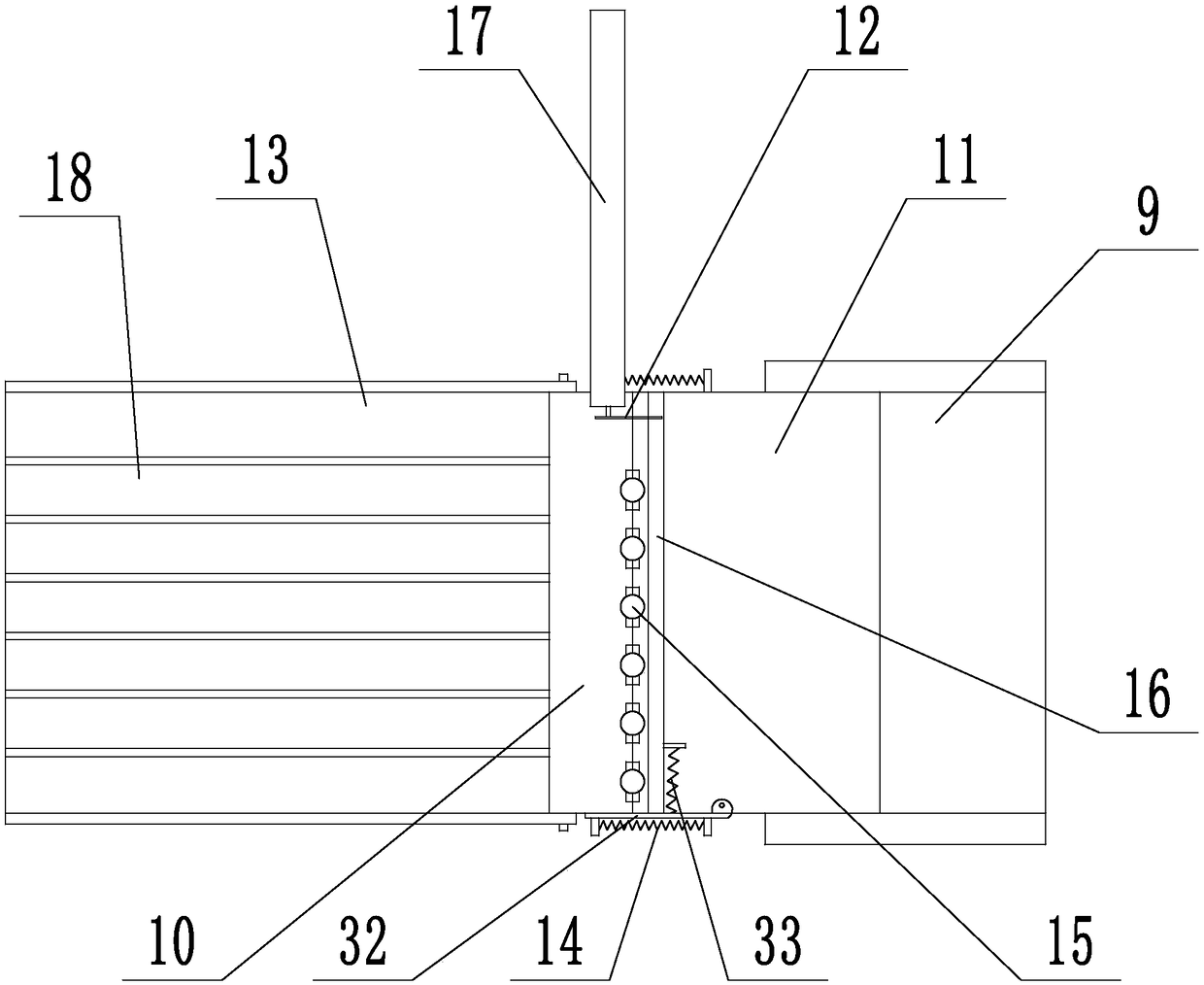

Image

Examples

Embodiment

[0025] Embodiment: a method for processing emblica, comprising the following steps: a. Pre-treatment of emblica, removing the core of fresh emblica, drying, crushing 50-80 mesh and sifting into emblica powder or directly beating and adding water 10-50 mesh Sieve into emblica slurry; b. preparation of solid medium, add carbon source and / or nitrogen source to emblica powder or emblica slurry, mix and sterilize, add sterile water to adjust water content to 20-50%; c 1. Sterilization, put the solid medium into the container and sterilize; d, inoculate and ferment, inoculate the fermentation strain after sterilizing and cooling, mix evenly and ferment, the fermentation temperature is 30-40 degrees Celsius, and the humidity is 50-90%. 7-20 days; e, drying, after the fermentation is finished, dry at a low temperature, the temperature does not exceed 80 degrees Celsius, and obtain the processed product of Amla emblica.

[0026] In step b, the carbon sources include quick-acting carbon...

Embodiment approach

[0029] The specific implementation method is as follows:

[0030] Method 1: Take the dried emblica after removing the core, crush it, and pass through a 50-mesh sieve; weigh 30 grams of emblica powder and 3 grams of rice flour, and put it in a 500ml triangular bottle, add 200ml of water; shake well, seal it with gauze, and tie it Tight; 121 ° C, sterilized for 45 minutes, inoculated into Aspergillus niger strains, and fermented at 36 ° C on a shaker at 200 rpm for 7 days to obtain liquid strains.

[0031] Take another 1,000 grams of emblica powder, add 120 grams of rice flour, add water to adjust the water content to 30%, mix well, sterilize at 121°C for 40 minutes, and after cooling to room temperature, inoculate 500ml of the above-mentioned Aspergillus niger liquid strain. Mix well , fermented at 36°C and 60% humidity for 10 days, poured out, and dried at 60°C to obtain it. The content of gallic acid in the processed emblica processed product was determined to be 12.53g / 100g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com