Method for preparing lithium ion battery negative electrode binder, and method for preparing lithium ion battery negative electrode material

A lithium-ion battery and negative electrode material technology, applied in the direction of electrode manufacturing, battery electrodes, electrode collector coating, etc., can solve the problems of less hydrogen bonds and low fluidity of rigid polymer binders, and achieve improved charging The effects of discharge cycle stability, high fluidity, and high rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

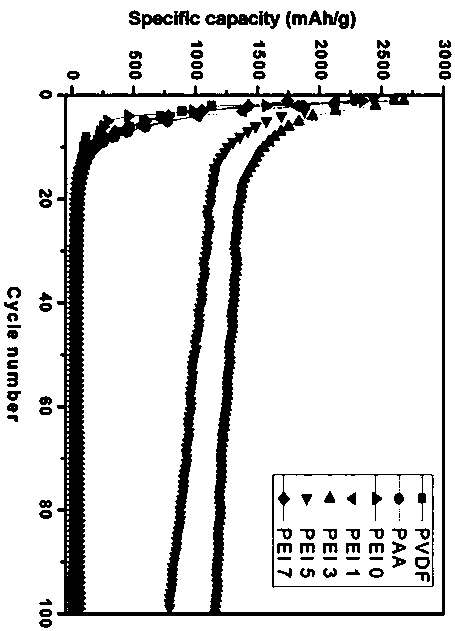

[0027] A preparation method of a lithium ion battery negative electrode binder, comprising the following steps: selecting hyperbranched PEI (polyethyleneimine), adding 3-5% mass fraction of crosslinking agent BDE (1,4-butanediol di glycidyl ether), to obtain the lithium ion battery negative electrode binder.

[0028] A preparation method of a lithium ion battery negative electrode binder, comprising the following steps: selecting hyperbranched PEI (polyethyleneimine) to prepare a PEI ethanol solution with a concentration of 0.125g / mL, adding 3- 5% mass fraction of the crosslinking agent BDE (1,4-butanediol diglycidyl ether), to obtain the lithium ion battery negative electrode binder.

[0029] The weight-average molecular weight of the added hyperbranched PEI is 60,000.

[0030] The mass fraction of the added cross-linking agent BDE is 3%.

[0031] The main effect that the present invention adopts PEI as binding agent is as follows:

[0032] 1) PEI itself provides a large n...

Embodiment

[0042] Firstly, 16 mL of 0.125 g / mL PEI (molecular weight: 60,000) ethanol solution was prepared, and 5% mass fraction of cross-linking agent BDE was added.

[0043] Then take out the ethanol solution containing 0.1g of PEI, grind it evenly with 0.3g of nano-silicon powder and 0.1g of acetylene black in an agate mortar, coat the copper foil to form a film, and place it in a vacuum oven at 60°C under vacuum Drying, during this period, through the ring-opening reaction of the amino group of PEI and the epoxy group of BDE, the PEI and silicon nanoparticles on the copper foil are cross-linked to form a hyperbranched network structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com