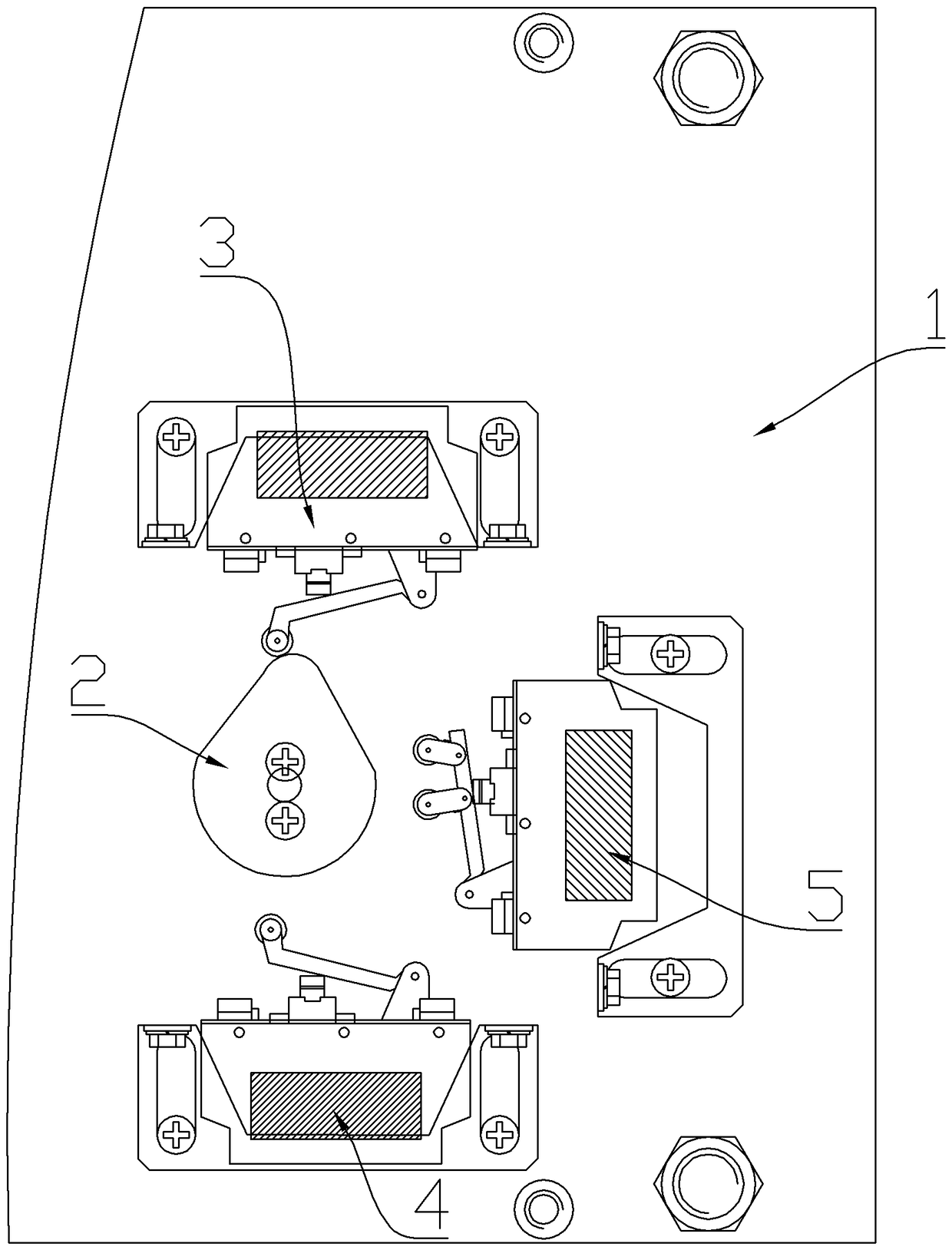

Three-station isolation switch and travel switch

A technology of isolating switch and travel switch, applied in the direction of air switch components, etc., can solve the problems of complex installation and debugging, low assembly efficiency, etc., to reduce the number of use, solve the complex installation and debugging, and simplify the logical relationship.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

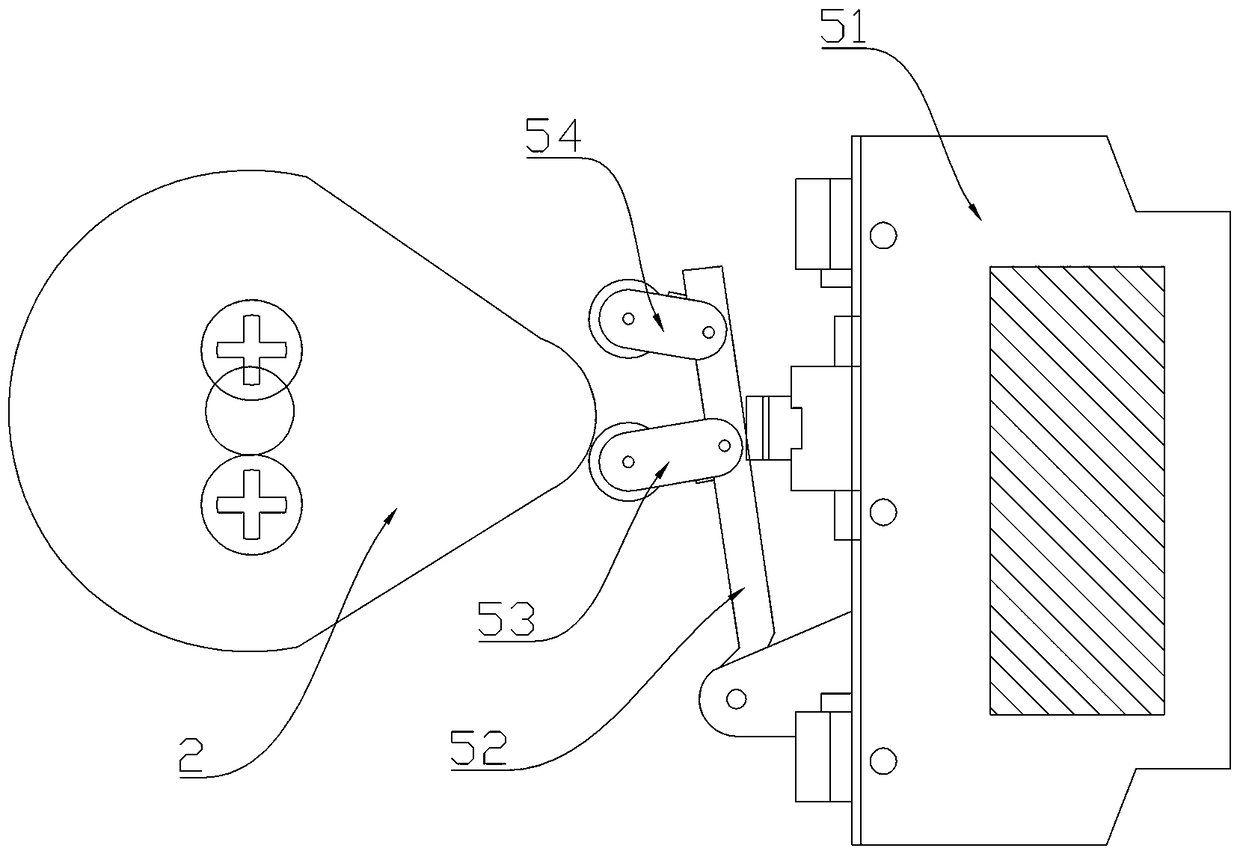

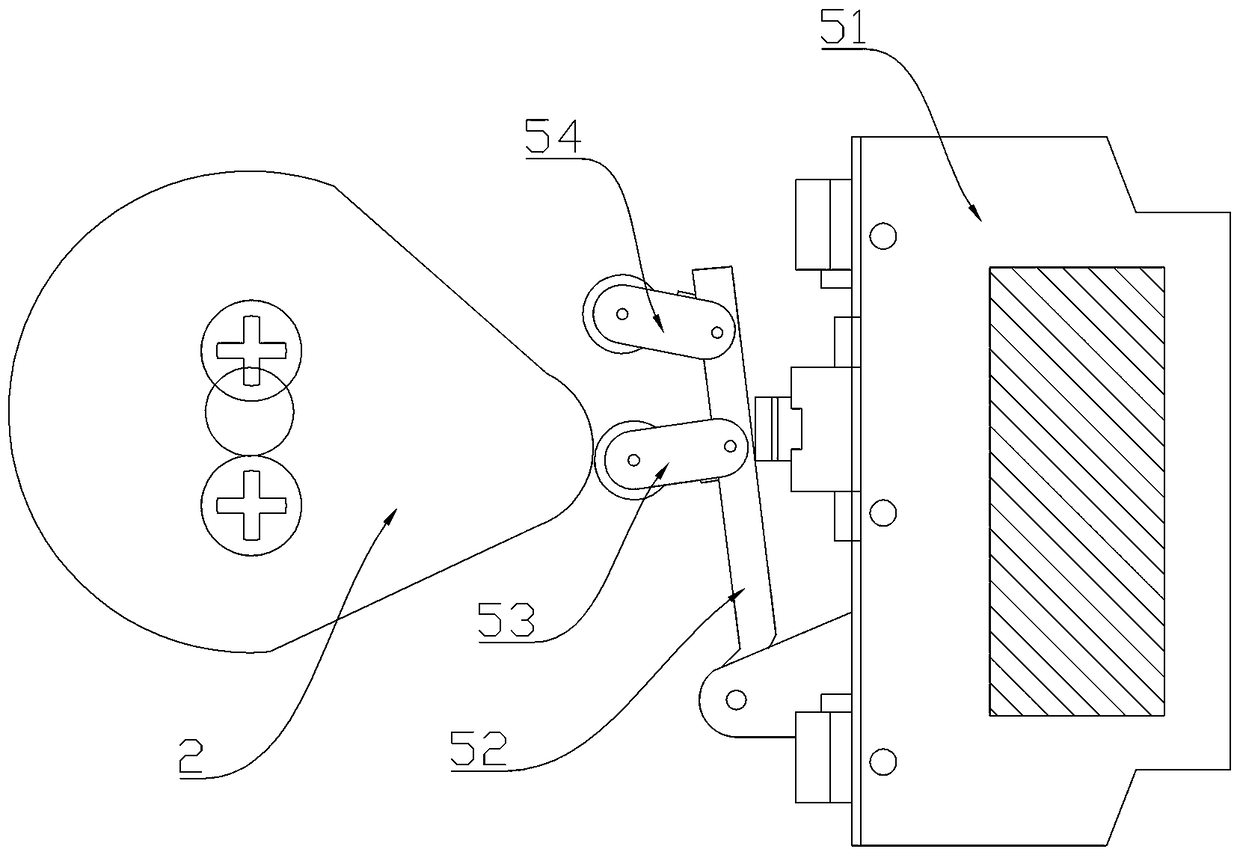

[0047] Specific embodiment 2 of the three-station isolating switch of the present invention, the difference between the structure of the three-station isolating switch in this embodiment and the structure of the above-mentioned three-station isolating switch is only: as Figure 12 and Figure 13 As shown, the signal rod 252 in this embodiment is provided with a two-way anti-sway member 253, and the swing stroke of the two-way anti-sway member 253 has a first anti-sway position and a second anti-sway position, and the cam 22 moves from the isolation closed position to the isolation position. In the opening position, the signal rod 252 is pressed by the two-way anti-swing member 253 in the first anti-swing position to trigger the opening travel switch, and when the cam 22 moves from the grounding closing position to the grounding opening position, it passes the two-way anti-swaying member in the first anti-swaying position. The rocker-stop member 253 presses the signal rod 252 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com