Electret transistor force sensor and preparation method thereof

A technology of force sensor and electret, which is applied in the field of sensing, can solve the problems that the monitoring of static or quasi-static pressure and deformation is difficult to realize, and achieve the effect of high sensitivity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This example illustrates the preparation method and force sensing performance of an electret transistor force sensor based on polypropylene porous electret film and pentacene organic semiconductor material.

[0022] Preparation of polypropylene porous electret film: Dissolve 1 gram of linear polypropylene particles in 15 grams of N,N-dimethylformamide organic solvent to form a uniform solution, and drop-coat the obtained polypropylene solution on a glass substrate and dried in a vacuum oven at 70°C for 8 hours to obtain a polypropylene film.

[0023] Foaming treatment of polypropylene porous electret film: place the above-mentioned polypropylene film in a high-pressure chamber, fill the pores in the polypropylene film with high-pressure gas, and then the high-pressure chamber is rapidly decompressed to ambient pressure, and the high-pressure gas in the film expands , generating bubbles with a pore size of tens of microns in the membrane.

[0024] Polarization treatment...

Embodiment 2

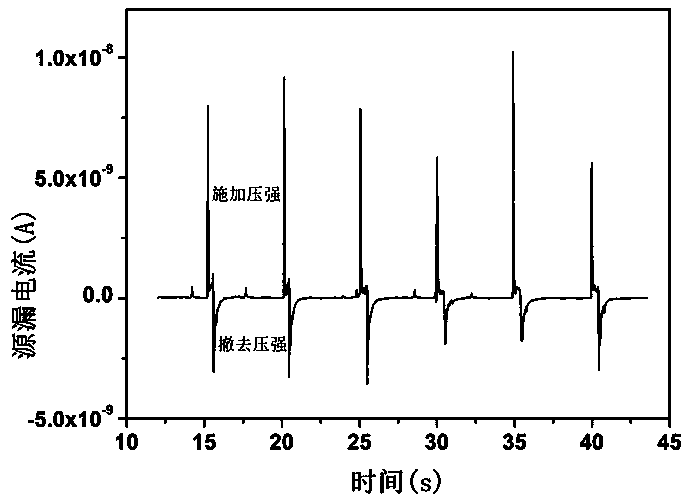

[0029] This example describes the preparation method of an electret transistor force sensor based on a polypropylene porous electret film and an organic semiconductor TIPS pentacene and its dynamic force sensing performance.

[0030] The preparation, foaming and polarization treatment process of the polypropylene porous electret film are consistent with those in Example 1.

[0031] Vacuum deposition of TIPS pentacene semiconductor layer: The TIPS pentacene organic semiconductor layer is deposited on the surface of polarized polypropylene porous electret film by vacuum thermal evaporation process. During the deposition process, the heating temperature of the quartz crucible was 252 °C, the thermal evaporation rate was 7 Å / s, and the final TIPS pentacene film was deposited with a thickness of 70 nm.

[0032] Preparation of source and drain electrodes: Copper source and drain electrodes are deposited on the TIPS pentacene film by vacuum thermal evaporation process to form a trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com