Heat treatment production line for high-strength stainless steel plate

A stainless steel and high-strength plate technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of uncontrollable deformation of steel plates, unguaranteed flatness, unusable steel plates, etc., to get rid of import dependence, avoid surface oxidation, and select materials proper effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

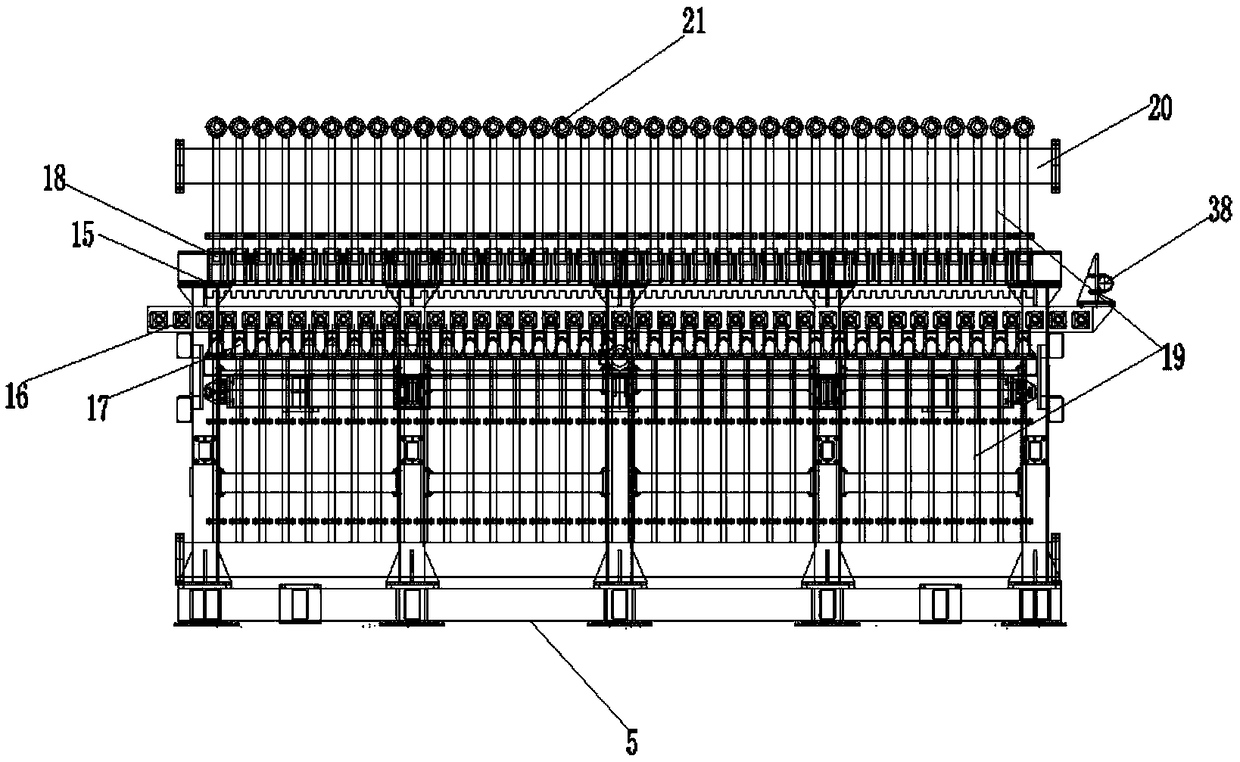

[0027] Such as figure 1 As shown, this embodiment is a heat treatment production line for stainless steel high-strength plates, including a heat treatment operation terminal 1, a quenching and feeding roller table 2, a roller hearth quenching furnace 3, a transition rack 4, a quenching machine tool 5, and a tempering and feeding roller table 6. The roller hearth tempering furnace 7 and the blanking roller table 8, the quenching feeding roller table 2 and the blanking roller table 8 are all equipped with a grasping manipulator 9.

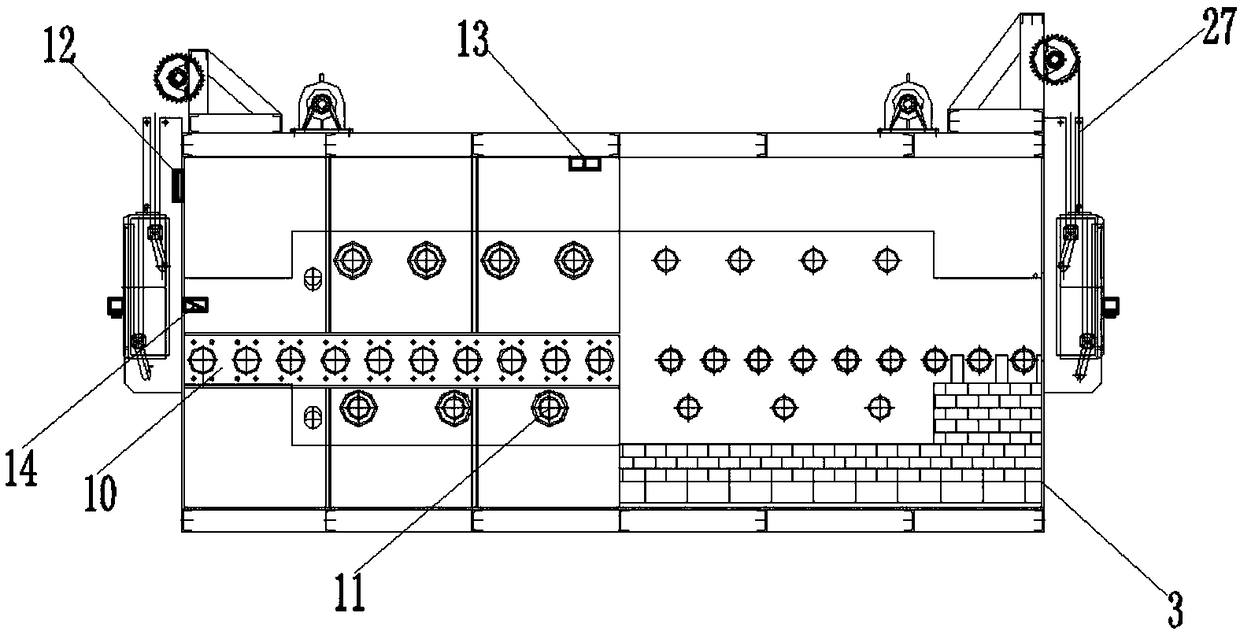

[0028] Such as figure 2 As shown, the roller hearth quenching furnace 3 includes a quenching roller table 10, a quenching heating tube 11, a differential pressure transmitter 12, a micro oxygen analyzer 13 and a first hot metal detector 14, and the quenching heating tubes 11 are arranged and distributed on the roller The top and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com