A regeneration method for phenol hydrogenation pd@cn catalyst

A catalyst and phenol technology, applied in the field of catalysis, can solve the problems of limited mass transfer, low phenol concentration, easy to block catalyst pores, etc., and achieve the effect of restoring catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

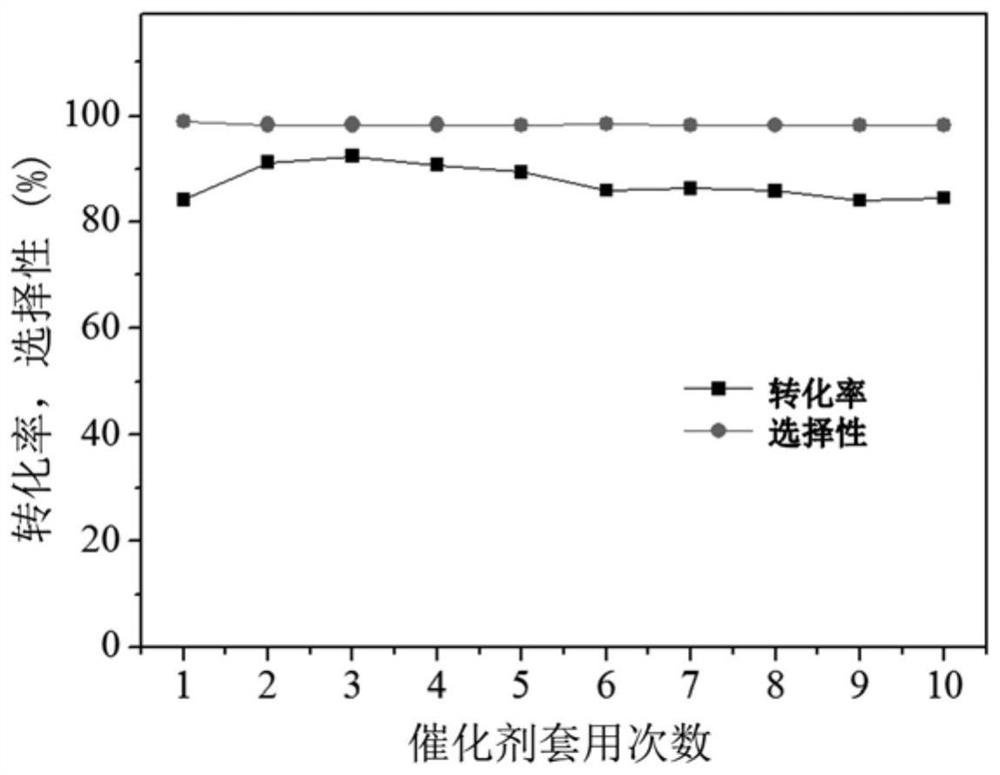

[0025] The mixture after phenol hydrogenation reaction catalyzed by Pd@CN catalyst was filtered and separated to recover the catalyst. The recovered catalyst was placed in the reactor, a certain amount of cyclohexane was added, the reactor was sealed, and hydrogen was replaced 5 times. at 110 o C, 0.5 MPa, 500 rpm for 60 min. After the catalyst was recovered by filtration, it entered the next phenol hydrogenation activity test experiment, which was applied 10 times in total. The change of catalytic performance of Pd@CN catalyst is as follows: figure 2 shown. The conversion rate and selectivity of phenol remained basically unchanged, showing good stability.

Embodiment 2

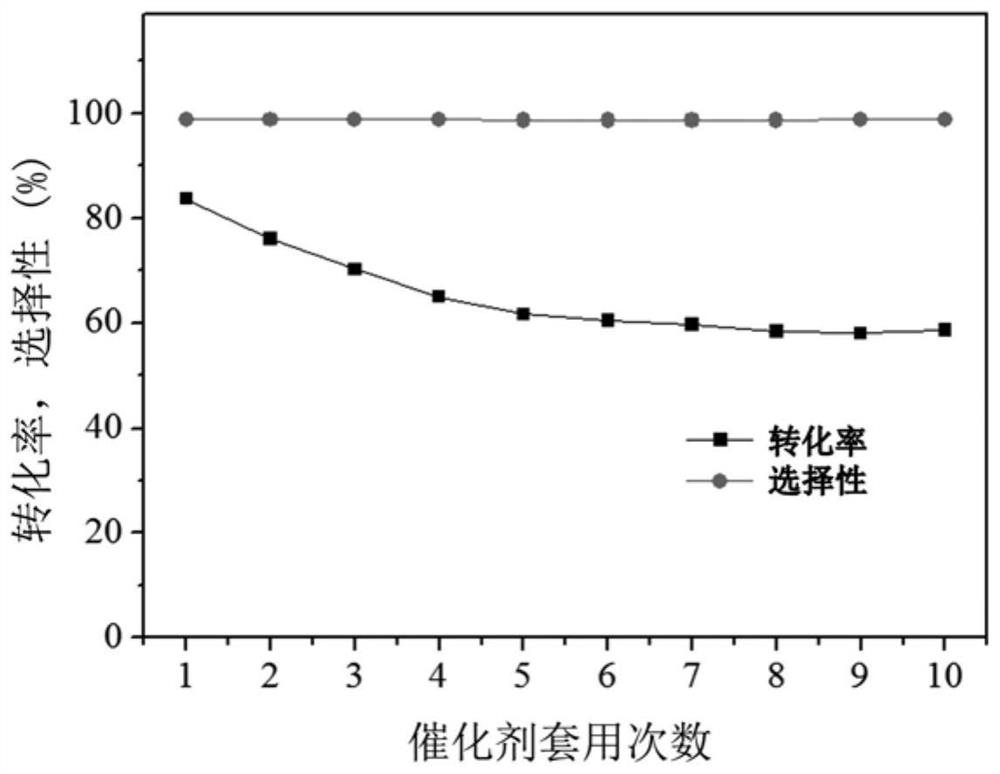

[0027] The mixture after the phenol hydrogenation reaction catalyzed by the Pd@CN catalyst was filtered and separated to recover the catalyst. The recovered catalyst was placed in a reactor, a certain amount of water was added, the reactor was sealed, and nitrogen replacement was used for 5 times. at 80 o C, 0.1 MPa, 100 rpm for 30 min. After the catalyst was recovered by filtration, it entered the next phenol hydrogenation activity test experiment, which was applied 10 times in total. The results showed that the selectivity of cyclohexanone remained basically unchanged, and the conversion of phenol decreased by about 15%.

Embodiment 3

[0029] The mixture after phenol hydrogenation reaction catalyzed by Pd@CN catalyst was filtered and separated to recover the catalyst. The recovered catalyst was placed in the reactor, a certain amount of ethanol was added, the reactor was sealed, and replaced with argon 5 times. at 140 o C, wash at 1.5 MPa, 300 rpm for 90 min. After the catalyst was recovered by filtration, it entered the next phenol hydrogenation activity test experiment, which was applied 10 times in total. The results showed that the selectivity of cyclohexanone remained basically unchanged, and the conversion of phenol decreased by about 25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com