Equipment for preparing lipid nanospheres

A kind of equipment and water phase technology, which is applied in the field of equipment for preparing liposphere colostrum, can solve the problems of undisclosed colostrum storage equipment, inability to adapt to industrial production, separation of oil phase and water phase, etc., and improve equipment utilization efficiency , reduce surface oil slick phenomenon, reduce the effect of phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

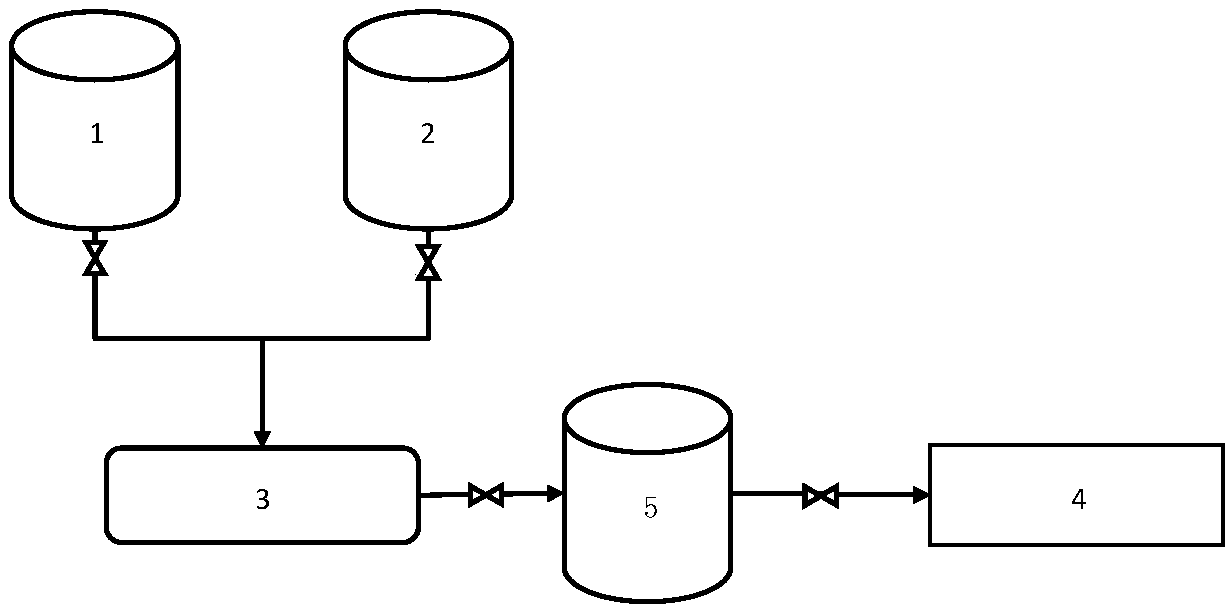

[0048] like figure 1 The described equipment for preparing lipid microsphere emulsion includes a water phase tank 1, an oil phase tank 2, a three-stage online disperser 3, a high-pressure homogenization device 4, and a storage tank 5. The water phase tank 1 and the oil phase tank 2 are connected to the inlet of the three-stage online disperser 3 through a connecting pipe, and the outlet of the three-stage online disperser is connected to the storage tank 5 through a connecting pipe, and the storage tank 5 is connected to the homogenizing equipment 4 . Valves are provided at the outlets of the water phase tank 1, the oil phase tank 2, the connecting pipe of the three-stage online disperser 3, and the storage tank 4. The valves on the connecting pipes of the water phase tank, the oil phase tank and the three-stage online disperser can adjust the mixing volume ratio of the water phase and the oil phase. The water phase tank and the oil phase tank are equipped with turbine agitat...

Embodiment 2

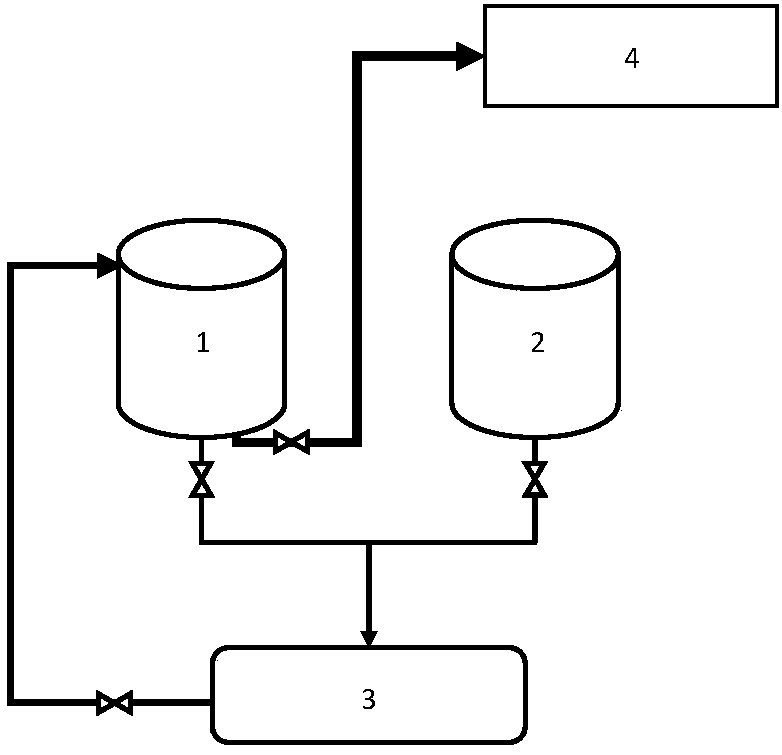

[0051] like figure 2 The described equipment for preparing lipid microsphere emulsion includes a water phase tank 1, an oil phase tank 2, a three-stage online disperser 3, and a homogenization device 4. The water phase tank 1 and the oil phase tank 2 are connected to the inlet of the three-stage online disperser 3 through a connecting pipe, the outlet of the three-stage online disperser is connected to the top of the water phase tank through a connecting pipe, and another outlet is set at the bottom of the water phase tank and passed through the connecting pipe Connected with homogenizing equipment 4. Valves are installed at the outlets of the water phase tank 1, oil phase tank 2, and connecting pipes of the third-stage online disperser 3. The valves on the connecting pipe of the disperser can adjust the flow rate to control the mixing volume ratio of the water phase and the oil phase. There are stirring devices to promote dissolution in both the water phase tank and the oi...

Embodiment 3

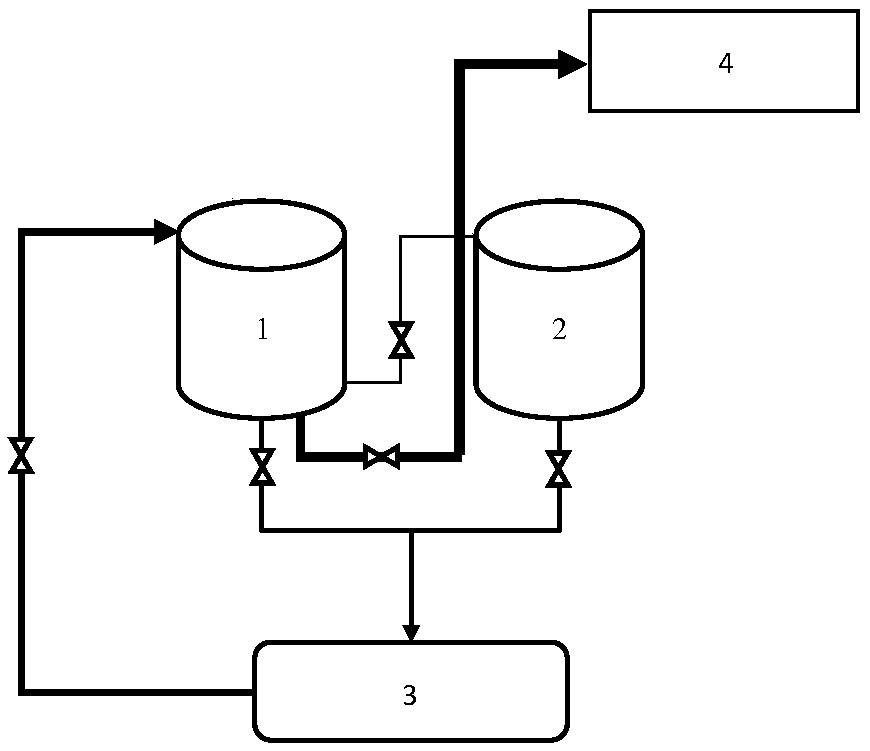

[0055] like image 3 In the described equipment for preparing lipid microsphere emulsion, on the basis of the equipment in Example 2, a connecting pipe is added between the bottom of the water phase tank 1 and the top of the oil phase tank, and the connecting pipe is provided with a valve.

[0056] image 3 The equipment completes the configuration of the water phase and the oil phase in the water phase tank 1 and the oil phase tank 2 respectively, by adjusting the valve on the connecting pipe between the water phase tank 2 and the three-stage online disperser 3, and the oil phase tank 2 and the three-stage online The valve on the connecting pipe of the disperser 3 allows the water phase and the oil phase to enter the three-stage online disperser 3 for shear emulsification according to the volume ratio of 5:1, and the sheared mixture flows into the water phase tank 1 through the connecting pipe. After the oil phase tank is emptied, close the valve on the connecting pipe betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com