Device and method for dynamic detection of mirror surface scratches

A dynamic detection and mirror technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that manual detection methods cannot meet the high-quality and high-efficiency production needs, light reflection interference on the mirror surface, and irregular shape of scratches, etc. , to achieve the effects of easy implementation, easy popularization and application, and efficient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

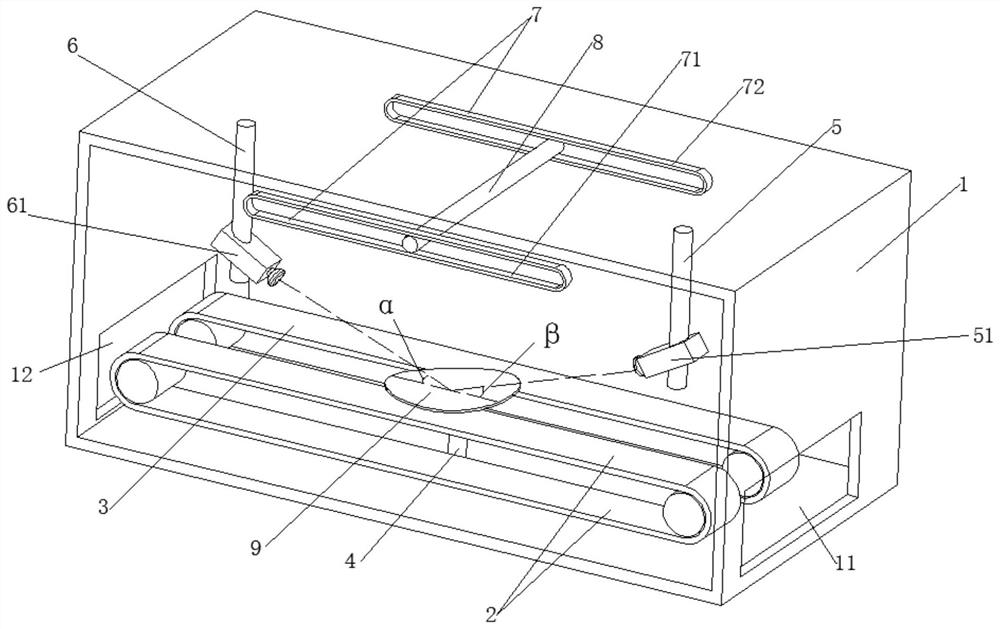

[0037] like figure 1 and figure 2 The mirror surface scratch dynamic detection platform shown includes a dark box 1, a first conveyor belt 2 and a second conveyor belt 3 for transmitting the lens 9 to be inspected, and a lifting rod 4 is arranged between the first conveyor belt 2 and the second conveyor belt 3 , the camera obscura 1 is also provided with a first camera fixing rod 5, a second camera fixing rod 6, a scanning lamp dynamic slide rail 7 and a scanning lamp tube 8, and the first camera fixing rod 5 and the second camera fixing rod 6 are arranged on the bracket Above the lifting bar 4, a first CCD camera 51 is fixed on the first camera fixing bar 5, a second CCD camera 61 is fixed on the second camera fixing bar 6, and the first CCD camera 51 and the second CCD camera 61 are also positioned at the lifting position. above the rod 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com