Overhead lines key parts monitoring system and detection method

A monitoring system and component technology, applied in the field of catenary, can solve the problem of failure to effectively monitor the force of components, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

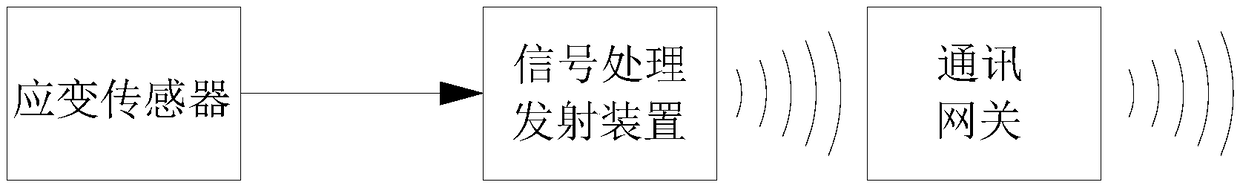

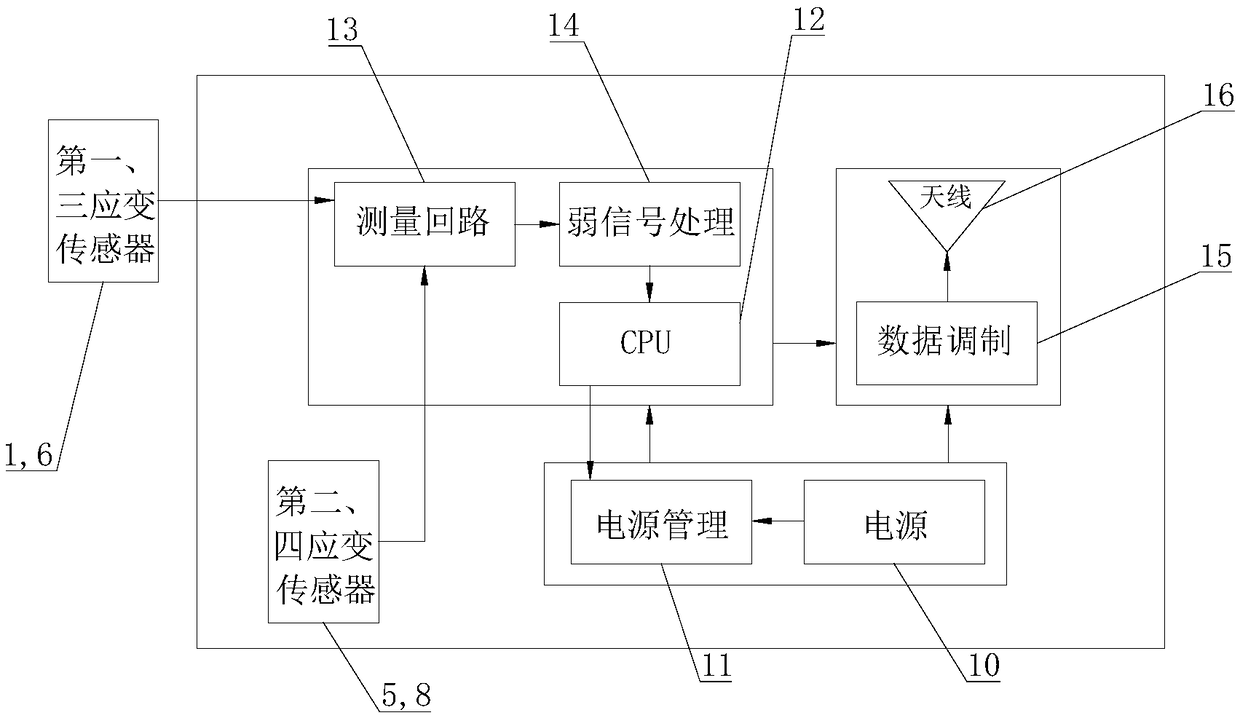

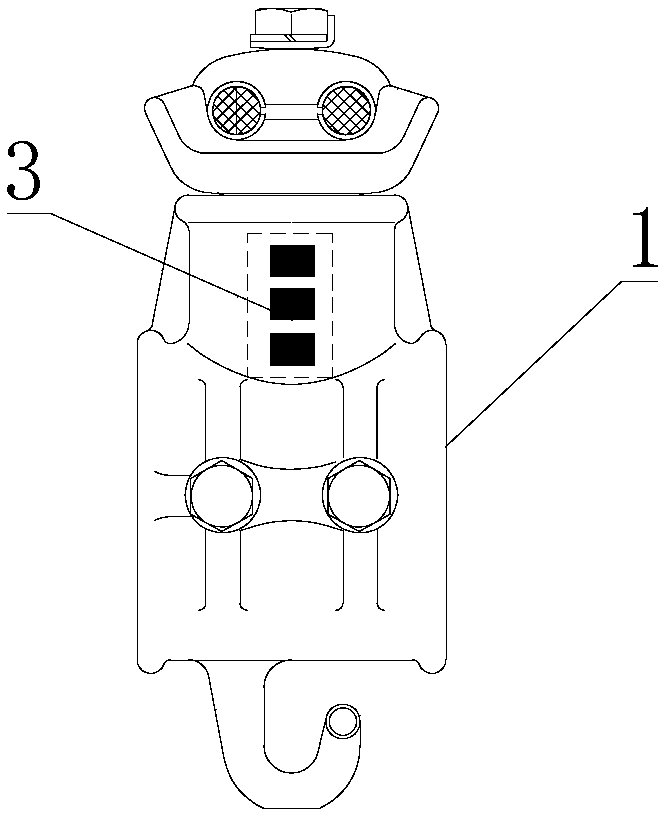

[0020] Such as figure 1 The shown provides a method for real-time monitoring of catenary components: the strain sensor group senses the force and transmits the signal to the signal processing transmitter, and the signal processed by the signal processing transmitter is transmitted to the communication Gateway, the signal received by the communication gateway is transmitted to the user for real-time monitoring. Specifically, the real-time detection method for the catenary cable seat and the anchor support positioning clip is as follows: a pair of strain sensor groups are respectively installed on the catenary cable seat and the anchor support positioning clip, and the strain sensor senses the position of the catenary cable seat and the anchor support position. The stress change on the clamp transmits the signal to the respective signal processing transmitters, and the signals transmitted from the strain sensor are processed by the signal processing transmitters, and then the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com