A safe water supply joint for motor vehicles and a water supply connection method

A connection method and technology of water joints, which are applied in the direction of hose connection devices, pipes/pipe joints/fittings, connections with fluid cut-off devices, etc., which can solve the problems of not having automatic opening and closing, safety accidents, and delays in water supply efficiency And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

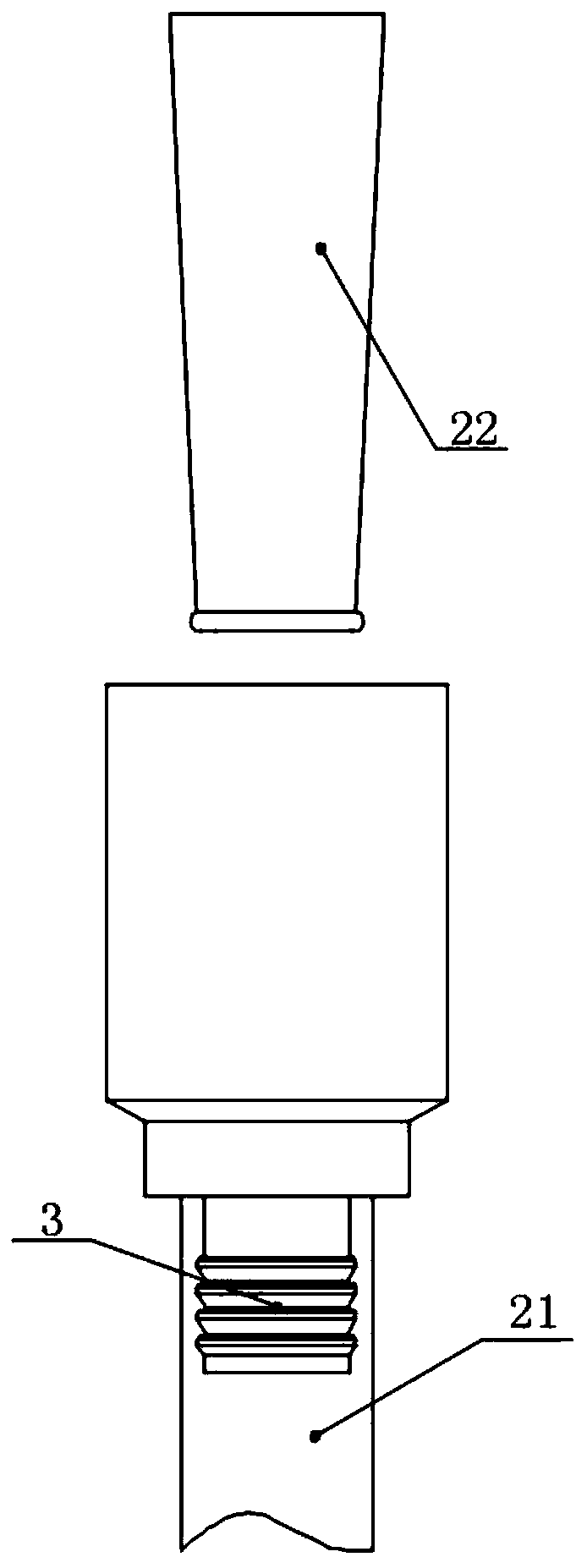

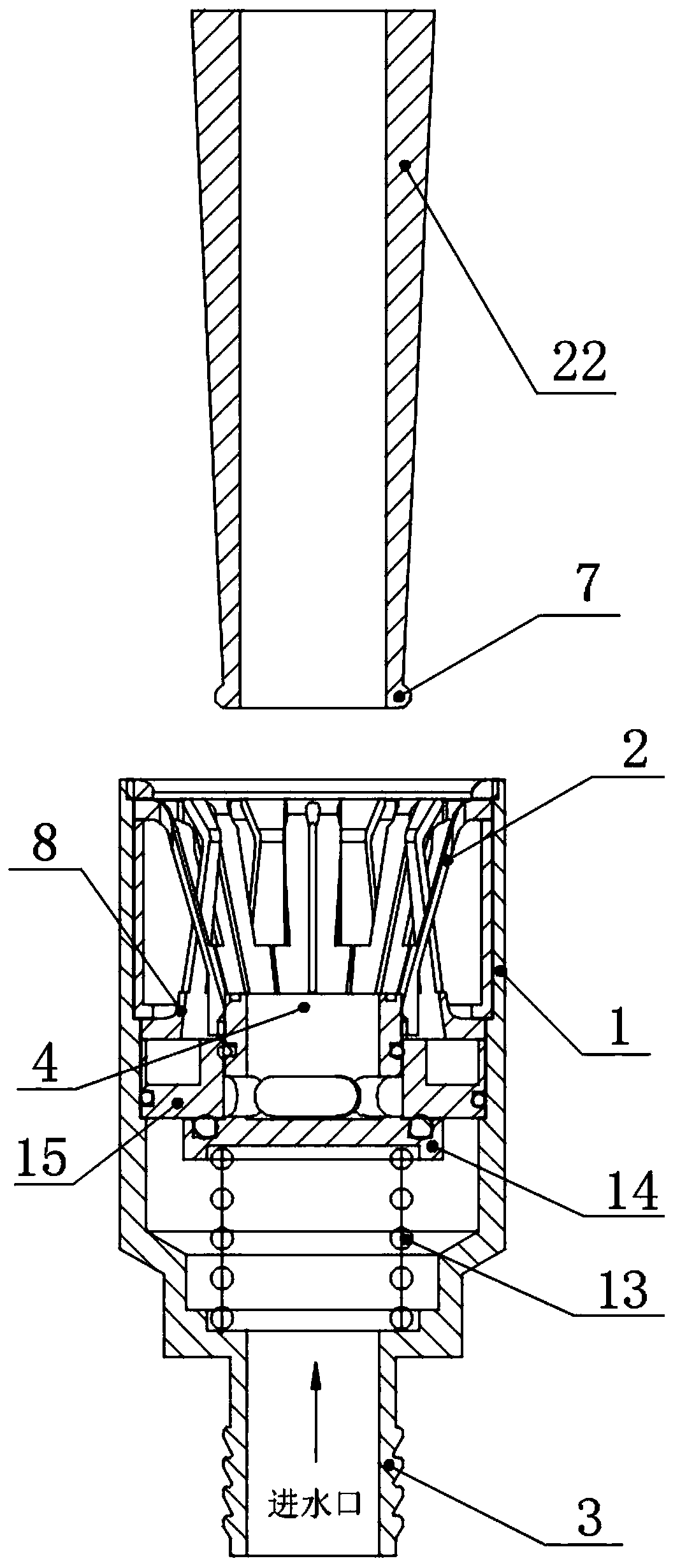

[0037] Such as Figure 1-5 As shown, a safety water supply joint for motor vehicles of the present invention includes a water supply joint housing 1, a check valve and a first water supply expansion ring 2, and the two ends of the water supply joint housing 1 are respectively large and small joints, and the big head is used to connect with the water supply joint. The connection end of the water supply joint 22, the small head is the water inlet pipe joint 3 for connecting with the water supply pipe 21, the lower end of the water supply joint housing 1 is provided with the water intake pipe joint 3, and the upper end of the water supply joint housing 1 is the installation cavity of the water supply joint 4. A check valve is provided at the lower part of the installation cavity 4 of the water supply joint; when the safe water supply joint and the water supply joint 22 are installed and connected, the check valve will be automatically triggered to open, and the water supply joint ...

Embodiment 2

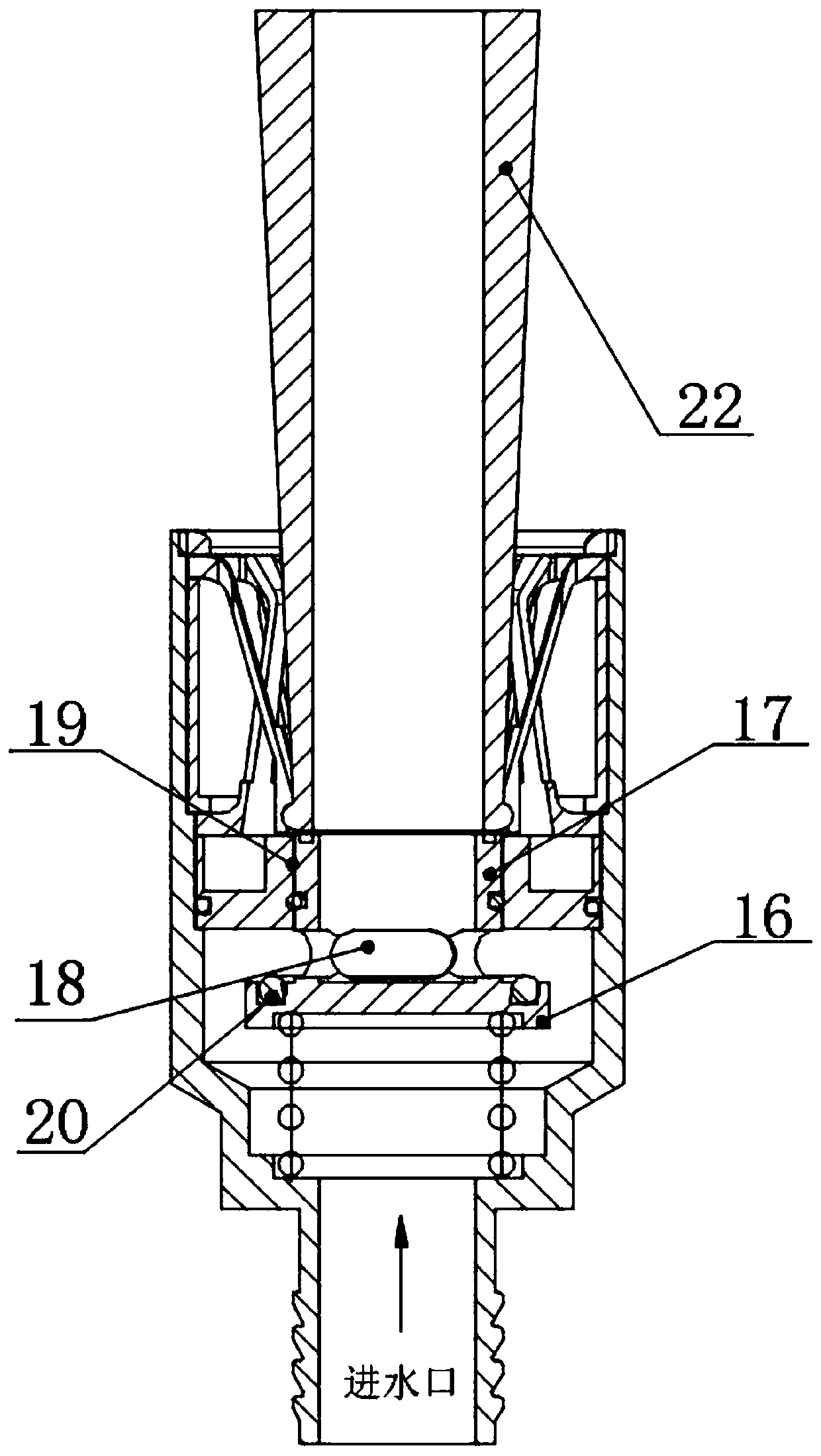

[0045] Such as Figure 1-5 As shown, the present invention is a safe water supply joint for motor vehicles. On the basis of Embodiment 1, the check valve includes a check valve spring 13, a check valve seat 14 and a check valve sleeve 15, and the check valve spring 13 It is arranged at the bottom of the installation cavity 4 of the water supply joint. The check valve seat 14 includes a seat plate 16 and a check valve core barrel 17. The check valve core barrel 17 is arranged on the upper end surface of the seat plate 16. 17 and the seat plate 16 are surrounded by a water hole 18, and the bottom end surface of the seat plate 16 is set on the check valve spring 13; The middle part of the return valve sleeve 15 is provided with a check valve core installation hole 19 , and the check valve core barrel 17 of the check valve seat 14 is sealed and inserted in the check valve core installation hole 19 . The upper end surface of the seat plate 16 surrounds the check valve core barrel ...

Embodiment 3

[0048] Such as Figure 1-5 As shown, a water supply connection method for a motor vehicle safety water supply joint is characterized in that it includes the steps:

[0049] Step 1, use the water inlet pipe joint 3 to connect with the water inlet pipe 21, and open the water inlet pipe 21;

[0050] Step 2. Insert the water supply joint 22 into the first water supply expansion ring 2, and the water supply joint 22 is fixed on the bottom end of the water supply joint limit block 5 through the raised retaining ring 7 provided around its end, Thereby, the water supply joint 22 is tightly connected with the check valve, and the water supply joint clamping block 10 of the second water expansion ring 8 is clamped on the water supply joint, and the water supply joint 22 is squeezed by the check valve of the check valve at the same time. seat 14, so that the check valve core barrel 17 moves downward in the check valve core mounting hole 19, the seat plate 16 is separated from the check ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com