Sulfur-removing, pressurizing and storing device for single-well casing gas

A technology for storage devices and well casings, which is applied in the direction of gas fuel, wellbore/well components, and production fluids, can solve the problems of high energy consumption, inapplicability, and low efficiency of booster pumps, and achieve energy consumption and structure simple and durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

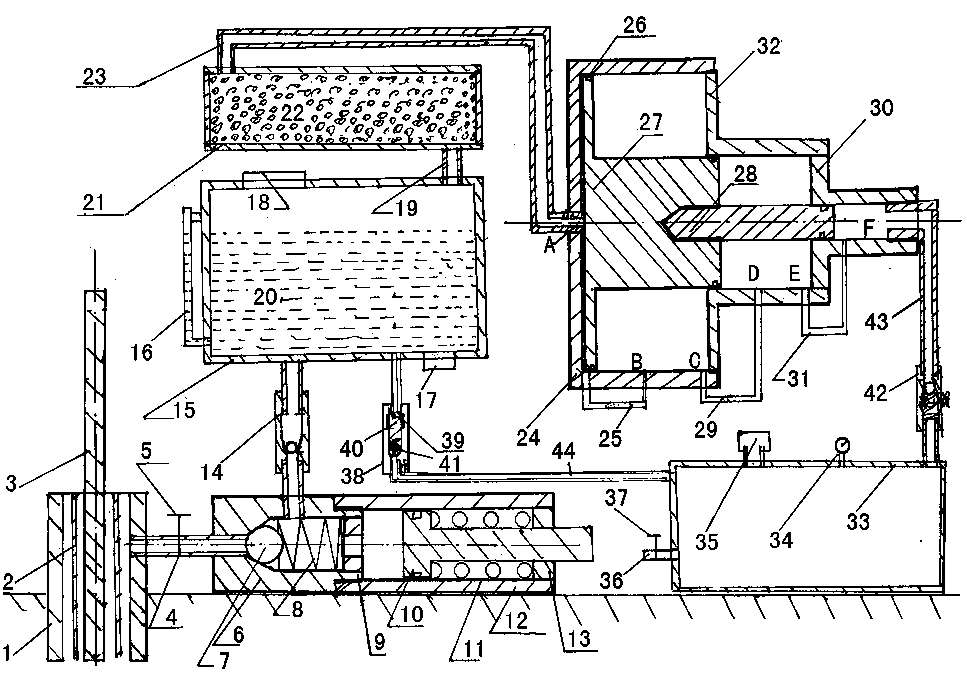

[0034] Embodiment 1, with reference to attached Figure 1-5 , the single well casing gas desulfurization pressurized storage device mentioned in the present invention, its technical solution is: include oil extraction exhaust device, chemical reaction device, natural gas drying device and multi-stage labor-saving gas compression device and compressed gas storage tank 33, The described oil extraction and exhaust device will be connected to the chemical reaction device through the gas outlet pipe after the natural gas between the casing pipe 1 and the oil pipe 2 is produced, and the chemical reaction device includes a reaction tank 15, a liquid level gauge 16, a liquid discharge Hole 17, injection hole 18, gas-collecting connecting pipe 19, chemical reaction liquid 20, the chemical reaction liquid 20 that is housed in the reaction tank 15 adopts sodium hydroxide solution, and one side of the reaction tank 15 is provided with a liquid level gauge 16, the top One side is provided ...

Embodiment 2

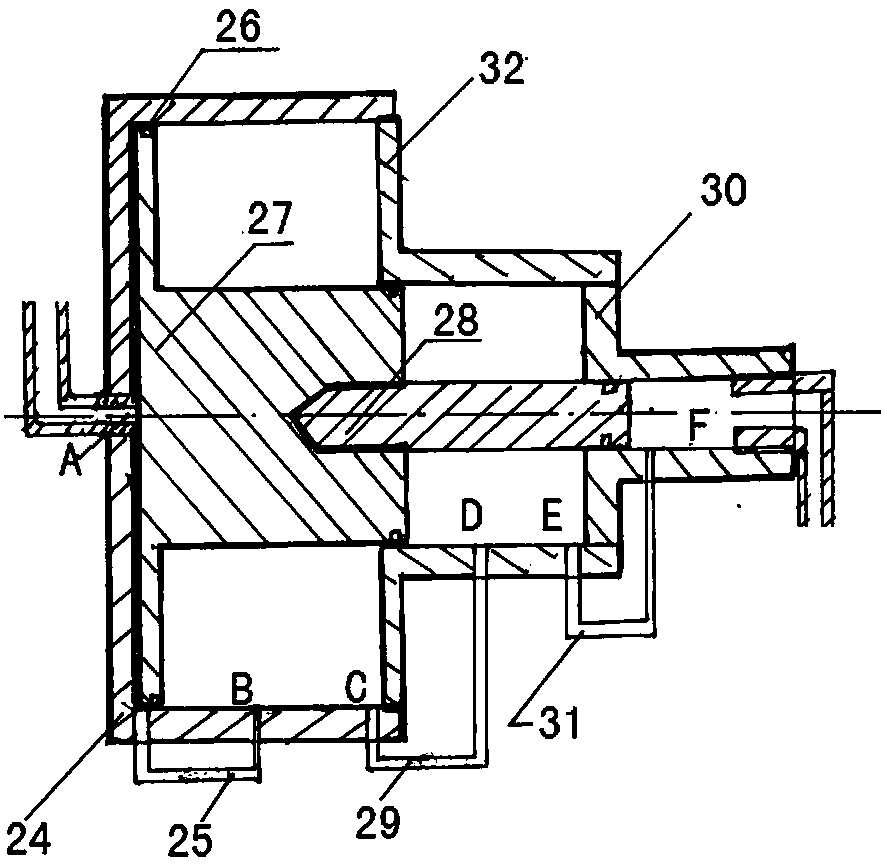

[0052] Embodiment 2, with reference to attached Image 6 The difference between the present invention and Embodiment 1 is: the left end face of the supercharging power cylinder 24 of the multi-stage labor-saving gas compression device is connected to the compression intake pipe 23, and the above-mentioned compression intake pipe 23 is formed by combining a dynamic sealing steel pipe and a PVC steel wire composite pipe , and the left end of the power piston 27 is connected and fixed through the dynamic sealing steel pipe, and the dynamic sealing steel pipe between the power piston 27 and the left end inner wall of the booster power cylinder 24 is provided with a plurality of air outlets, that is, the A place. Moreover, the inner wall of the left end of the power piston 27 and the left end of the supercharging power cylinder 24 is provided with a limiting block 47, and the position of the intake end of the supercharging air supply pipe 25 moves to the right.

[0053] The PVC ste...

Embodiment 3

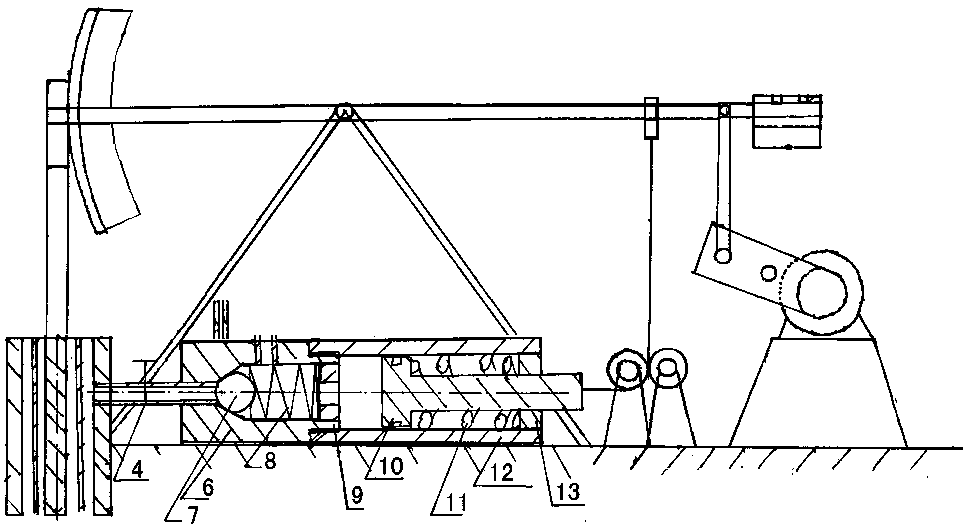

[0058] Embodiment 3, with reference to attached Figure 10 The difference between the technical solution mentioned in the present invention and Embodiment 2 is that one end of the compressed air intake pipe 23 is connected to the gas dryer 21, the other end is connected to the B of the booster power cylinder 24, and the power piston 27 is connected to The left end is connected with the dynamic seal shaft, and the outer end of the dynamic seal shaft is connected by a wire rope, and the wire rope is connected to the rear end of the beam of the beam pumping unit by going around the fixed pulley, so that the beam moves up and down at any time, moving with the wire rope, and then The steel wire rope is driven to move with the dynamic seal shaft, thereby giving the power piston 27 an external force.

[0059] The use method of the present invention differs from Embodiment 1 in that: the pressurization process of the multi-stage labor-saving gas compression device is different, specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com