Continuous construction method for aluminum alloy template for comprehensive pipe rack

A technology of aluminum alloy formwork and integrated pipe gallery, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of difficult demoulding, low reuse rate, and consumption of wood resources, and achieve smooth and clean surface quality, save Effects of construction cost and construction environment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the drawings and embodiments.

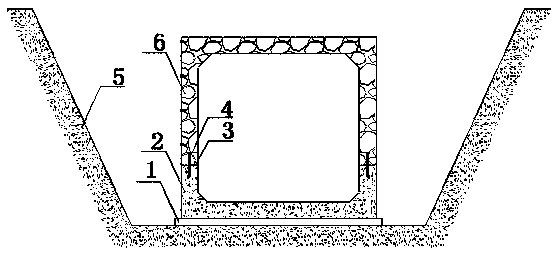

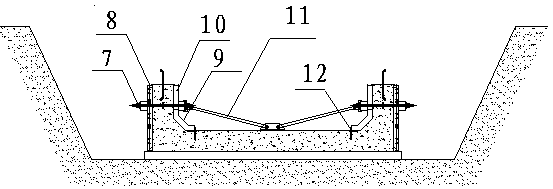

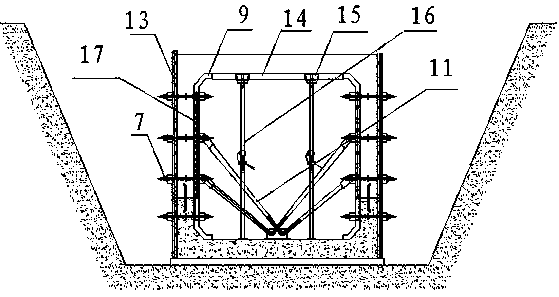

[0036] Refer to figure 1 , A continuous construction method of aluminum alloy formwork for integrated pipe gallery. The main structure of the integrated pipe gallery is divided into two layers of construction, namely the construction of bottom plate and guide wall 2, and the construction of wall and roof 6. Expansion joints are divided into sections according to the structural design in the horizontal direction, horizontal construction joints are set in the vertical direction, water-stop steel plates 4 and rubber water-stop belts are installed at the positions of the construction joints, the first concrete pouring bottom plate and guide wall 2, and the second concrete pouring wall and For the top plate 6, there are 2 sets of combined aluminum alloy templates for the first pouring, 1 set of aluminum alloy templates for the second pouring, and 3 sets of early dismantli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com