Manufacturing method of tear-resistant ventilating type blended knitted fabric

A technology of knitted fabric and production method, which is applied in the directions of knitting, warp knitting, textile and papermaking, etc., can solve the problems of poor air permeability and poor tear resistance of knitted fabrics, and achieves high production efficiency, stable structure and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

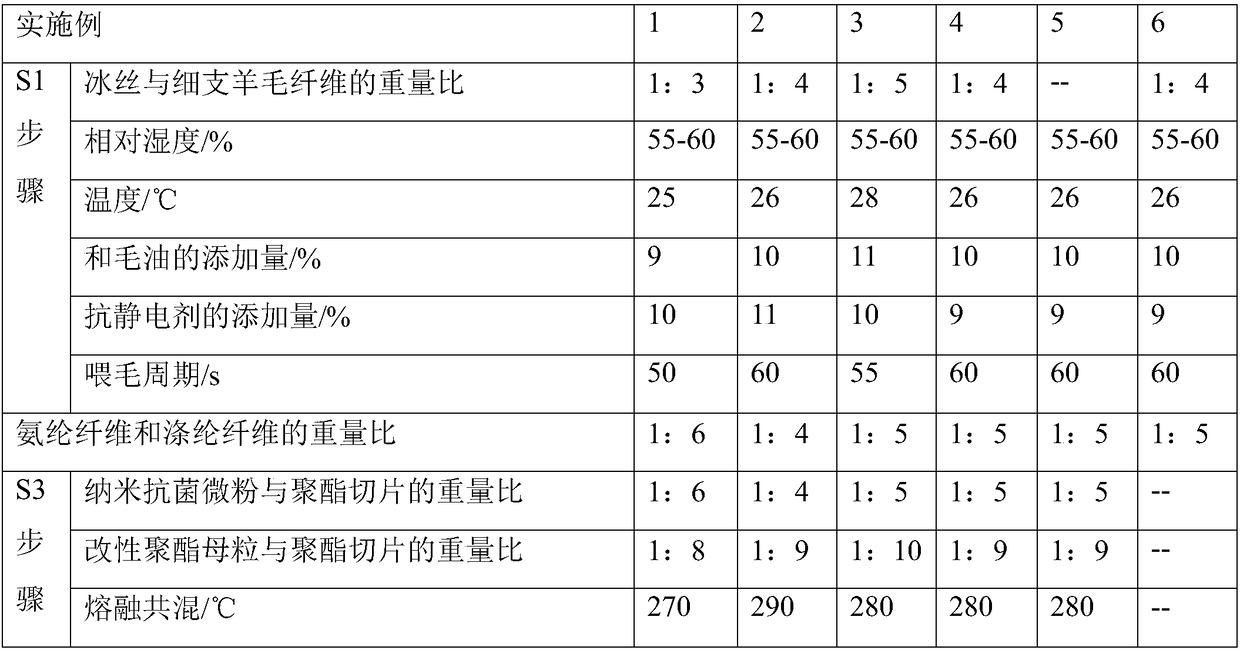

[0027] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

[0028] A method for making a tear-resistant and air-permeable blended knitted fabric, comprising the following steps:

[0029] Preparation of S1 blended yarn: Mix ice silk and fine wool fiber according to weight ratio to obtain blended yarn raw material, through carding, blending, beating, opening, slivering, drawing, spinning and automatic winding Spinning is carried out in the process to prepare blended yarn;

[0030] S2 Preparation of spandex-coated polyester yarn: mix spandex fiber and polyester fiber according to the weight ratio to obtain spandex-coated polyester yarn raw material, and prepare spandex-coated polyester yarn through fiber blending process;

[0031] S3 Preparation of modified polyester fiber: Melt blend nano-antibacterial micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com