A coal chemical gasifier

A technology of gasifier and coal chemical industry, which is applied in the direction of gasification process, granular/powdered fuel gasification, petroleum industry, etc. It can solve problems such as work efficiency needs to be improved, the overall structure is scattered, and device linkage cannot be realized, so as to achieve improvement Speed, improved combustion effect, improved combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

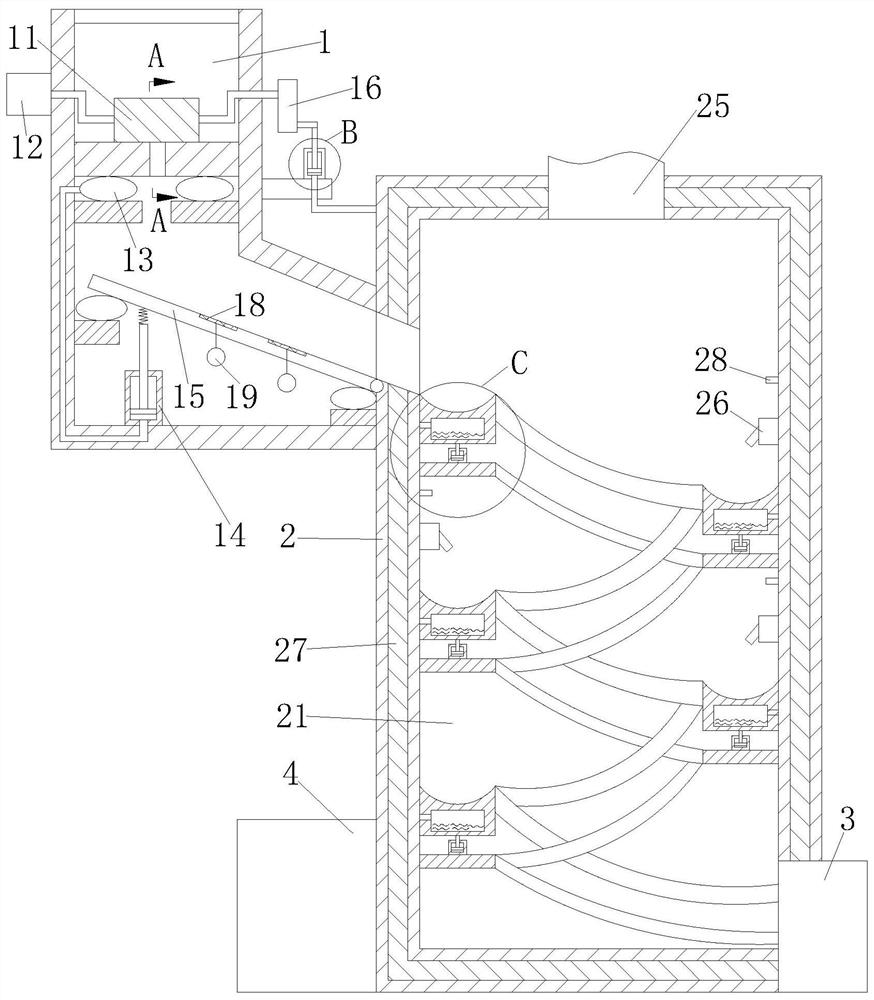

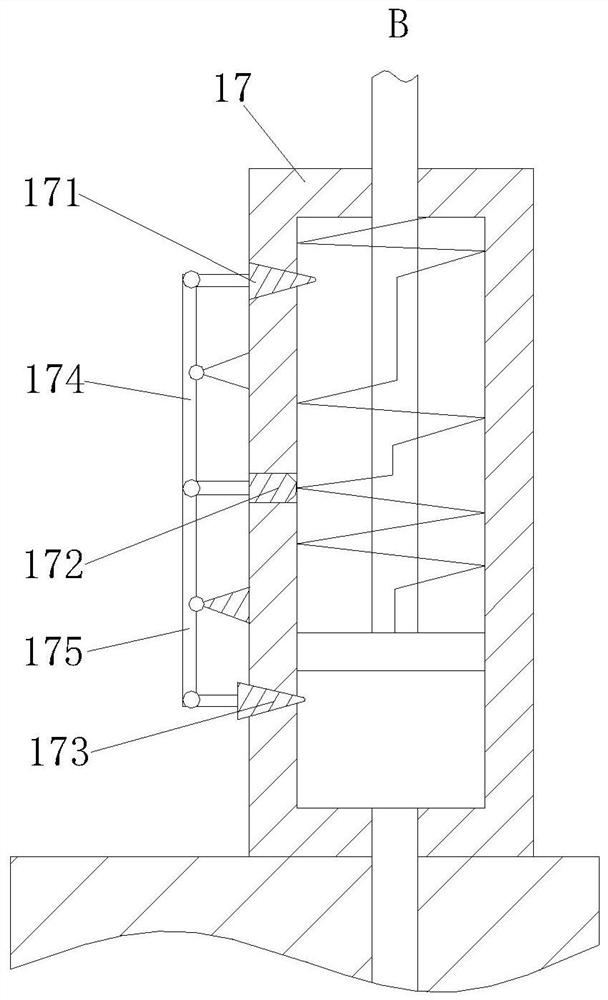

[0024] As an embodiment of the present invention, the grinding device 11 includes a roller 111 and a grinding block 112, the roller 111 is eccentrically arranged, and the roller 111 is connected to the output shaft of the motor 12; the radius of motion of the roller 111 greater than the radius of the grinding groove 113; the grinding block 112 is provided with a grinding groove 113, the grinding groove 113 is tangent to the outer ring of the roller 111, and a discharge groove 114 is arranged below the grinding groove 113. When working, the coal block enters from the feed pipe, and the roller 111 fully cooperates with the grinding groove 113 of the grinding block 112 to grind the coal block into fine coal powder, and the coal powder falls out from the discharge chute 114; wherein the roller 111 The eccentric setting, and the grinding groove 113 is set tangent to the outer ring of the roller 111, so that the coal block can be quickly ground into coal powder, and the working effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com