Ultraviolet cured high-anti-fouling matte floor paint and preparation method thereof

An ultraviolet light and antifouling technology, applied in the field of coatings, achieves the effects of simple preparation method steps, strong operability and excellent fouling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) A preparation method of UV-curable high stain resistance matt floor coating, including the following steps:

[0036] (1) Raw material preparation

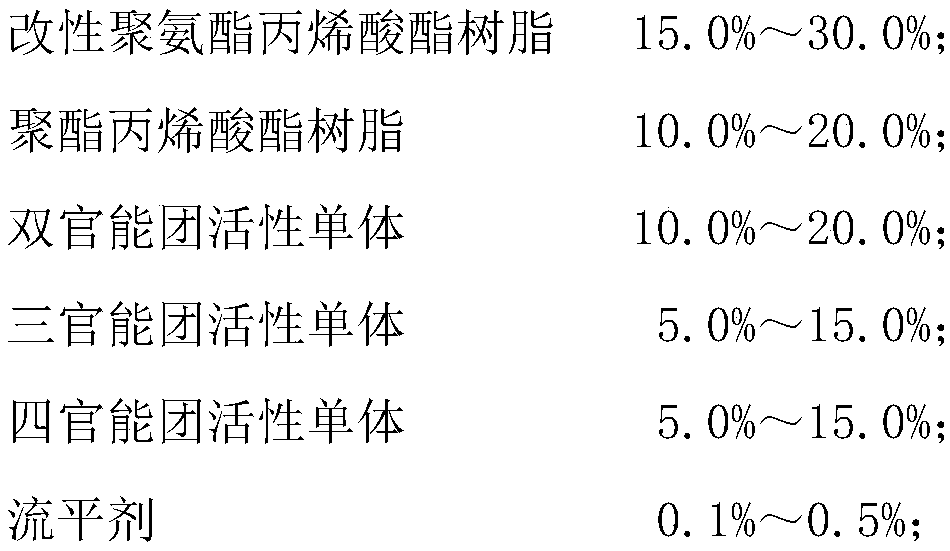

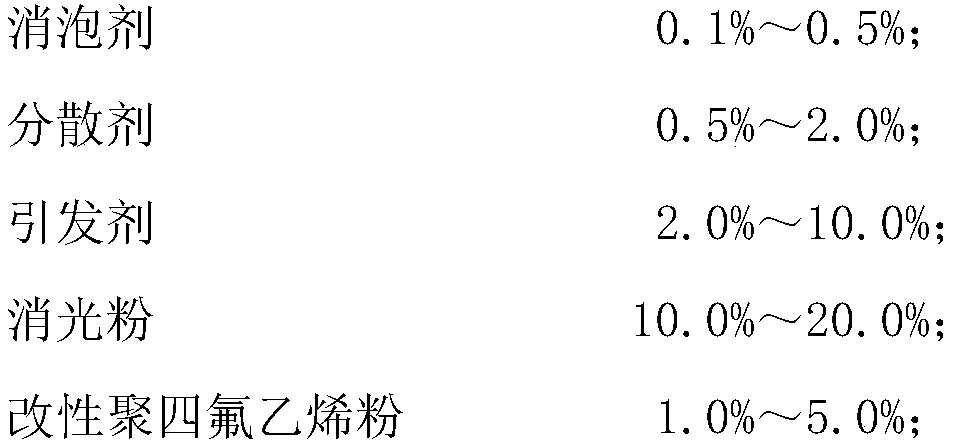

[0037] Prepare raw materials according to the mass percentage of raw material composition:

[0038] Modified polyurethane acrylate resin 15.0%, using hexafunctional urethane acrylate modified by silicone, produced by UV resin manufacturer, resin grade is DCHL-1. The modified polyurethane acrylate resin uses benzyl trimethicone, hydroxypropyl dimethacrylate and isophorone diisocyanate for epoxy ring opening and chain extension reaction to obtain the required silicone modification Polyurethane acrylate.

[0039] Polyester acrylate resin 20.0%, using Sartomer's trifunctional product, model CN2255.

[0040] The bifunctional monomer is 20.0%, and the 1,6-hexanediol diacrylate available in the professional market is used.

[0041] The triacyl group monomer is 5.0%, and the trimethylolpropane trimethacrylate available in the professiona...

Embodiment 2

[0060] (1) A preparation method of UV-curable high stain resistance matt floor coating, including the following steps:

[0061] (1) Raw material preparation

[0062] Prepare raw materials according to the mass percentage of raw material composition:

[0063] Modified polyurethane acrylate resin 25.9%, (same as Example 1).

[0064] Polyester acrylate resin 10.0%, (same as Example 1).

[0065] The bifunctional monomer is 10.0%, using the diethanol dimethacrylate available in the professional market.

[0066] The triacyl group monomer is 15.0%, using pentaerythritol triacrylate available in the professional market.

[0067] The tetrafunctional monomer is 15.0%, and the pentaerythritol tetraacrylate available on the professional market is used.

[0068] Leveling agent 0.1%, (same as Example 1).

[0069] Antifoaming agent 0.5%, (same as Example 1).

[0070] Dispersant 0.5%, (same as Example 1).

[0071] The initiator is 2.0%, using the products of Hunan Xinyu Company, the models are 184, 907, TPO....

Embodiment 3

[0078] (1) A preparation method of UV-curable high stain resistance matt floor coating, including the following steps:

[0079] (1) Raw material preparation

[0080] Prepare raw materials according to the mass percentage of raw material composition:

[0081] Modified polyurethane acrylate resin 30.0%, (same as Example 1).

[0082] Polyester acrylate resin 15.0%, (same as Example 1).

[0083] The bifunctional monomer is 15.0%, using triethylene glycol dimethacrylate available in the professional market.

[0084] The triacyl group monomer is 10.0%, and the propylene oxide glycerol triacrylate available in the professional market is used.

[0085] The tetrafunctional monomer is 8.4%, using dipentaerythritol pentaacrylate available in the professional market.

[0086] Leveling agent 0.3%, (same as Example 1).

[0087] Antifoaming agent 0.3%, (same as Example 1).

[0088] Dispersant 1.0%, (same as Example 1).

[0089] The initiator is 7.0%, using the products of Hunan Xinyu Company, the models are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com