Graphene zinc oxide conductive coating

A technology of zinc oxide and conductive coatings, applied in conductive coatings, epoxy resin coatings, coatings, etc., can solve the problems of short shelf life of zinc oxide conductive coatings, affecting the storage stability of conductive coatings, and weak interaction, etc., to achieve Improve storage stability, good electrical conductivity, and ensure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7 and comparative example 1~3

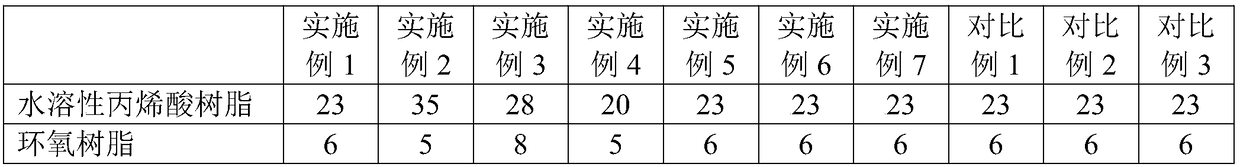

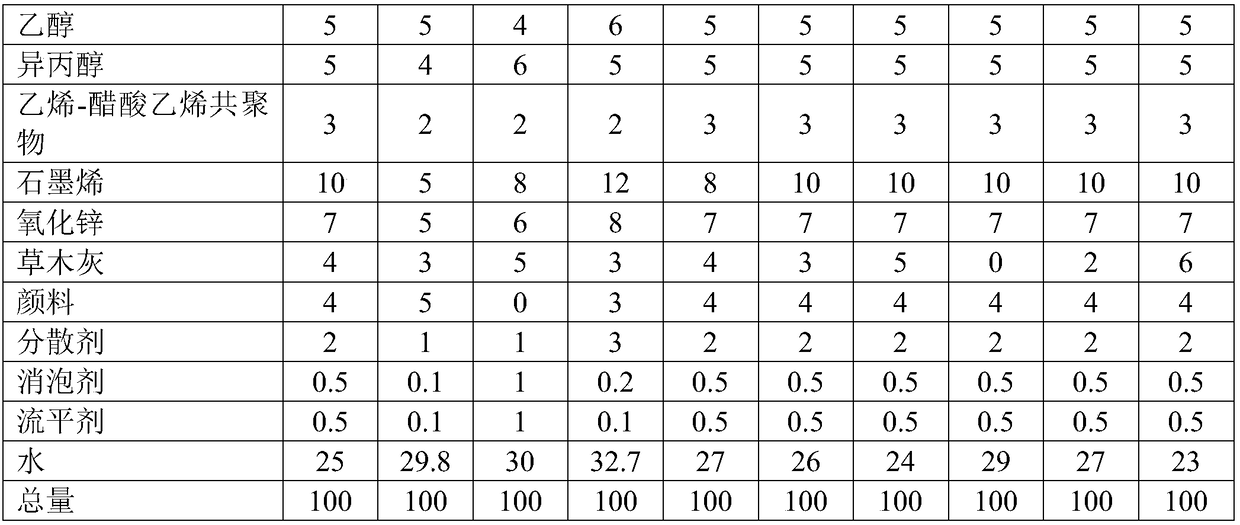

[0038] The graphene zinc oxide conductive coating component content of embodiment 1~7 and comparative example 1~3 is as shown in table 1;

[0039] The preparation method of the graphene zinc oxide conductive coating of embodiment 1~7 and comparative example 1~3 is as follows:

[0040] S1. Ethanol, isopropanol and water are formulated into solvents, and the solvent is divided into the first solvent and the second solvent with a volume ratio of 1:3; the water-soluble acrylic resin is divided into the first water-soluble acrylic acid of equal quality Resin and the second water-soluble acrylic resin; the first solvent, the first water-soluble acrylic resin, pigment, dispersant, zinc oxide, rice straw ash, and defoamer are uniformly mixed and ground to obtain a slurry;

[0041] S2. Mix the slurry in step S1. with the second solvent, the second water-soluble acrylic resin, epoxy resin, ethylene-vinyl acetate copolymer, graphene, and leveling agent to prepare graphene zinc oxide Con...

Embodiment 1

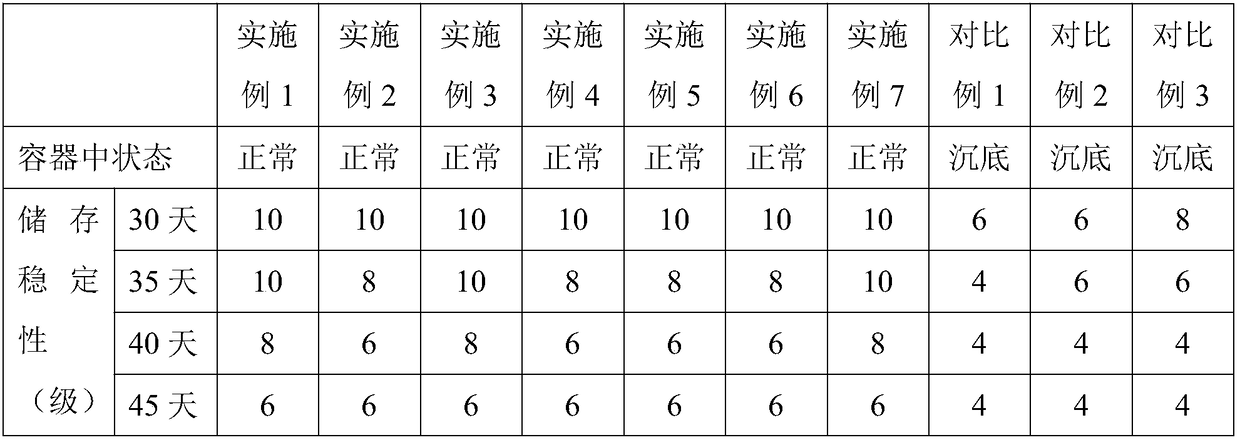

[0059] Embodiment 1 and embodiment 6~7 compare, and as can be known, the storage stability of embodiment 1 and embodiment 7 is obviously better than embodiment 6, but the electrical conductivity of embodiment 7 is slightly weaker than embodiment 6, generally speaking, implementation Example 1 and Example 7 are better than Example 6, so the performance of the graphene zinc oxide conductive coating obtained when the content of rice stalk plant ash is 4%~5% is better. Wherein the conductive property of embodiment 1 is better than embodiment 7, so the performance of the graphene zinc oxide conductive paint that makes when the content of rice stalk plant ash is 4% improves further.

[0060] And in the graphene conductive paint of comparative example 1, do not add rice straw plant ash, the storage stability of the graphene zinc oxide conductive paint that makes is relatively poor; Less than 3%, the storage stability of the prepared graphene zinc oxide conductive coating has not been...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com