SiAlCN(O) ceramic nano fiber, and preparation method and application thereof

A nanofiber and ceramic technology, applied in the field of SiAlCN ceramic nanofibers and their preparation, can solve problems such as application field limitations, and achieve the effects of simple process operation, low sintering temperature and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

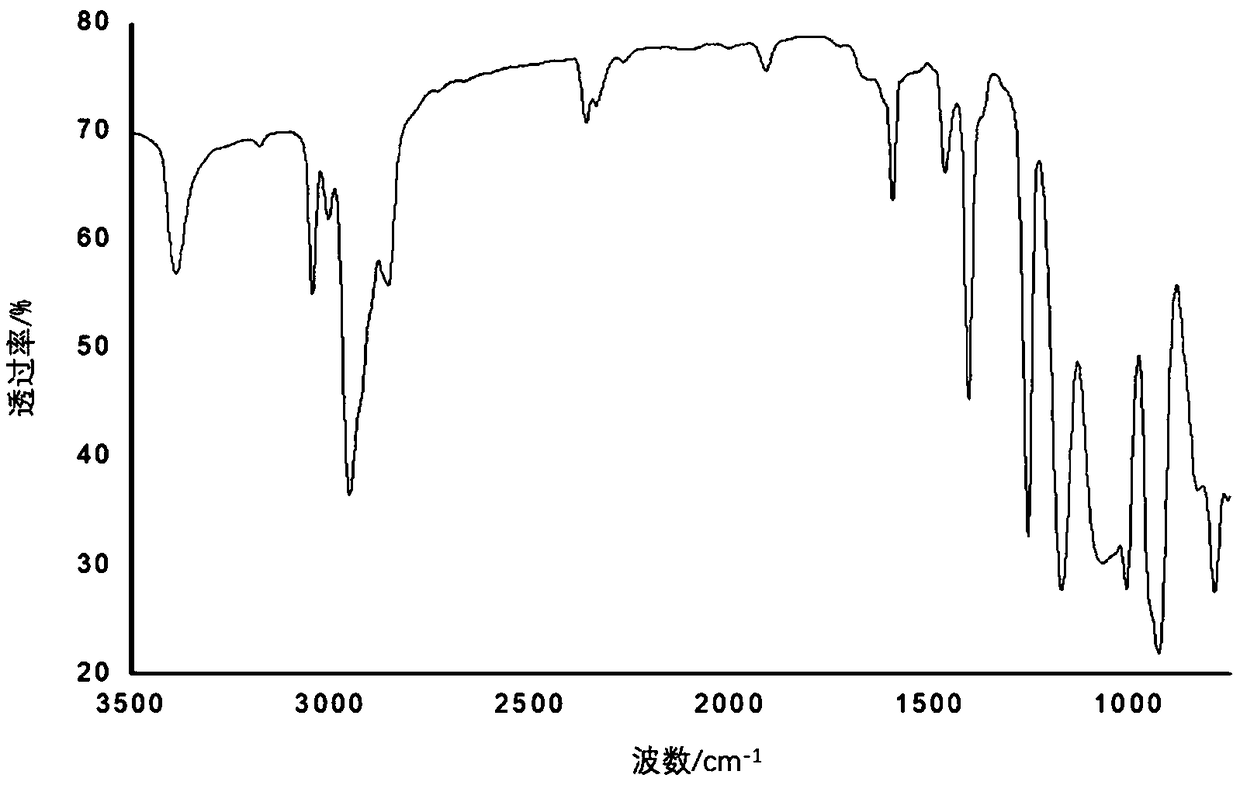

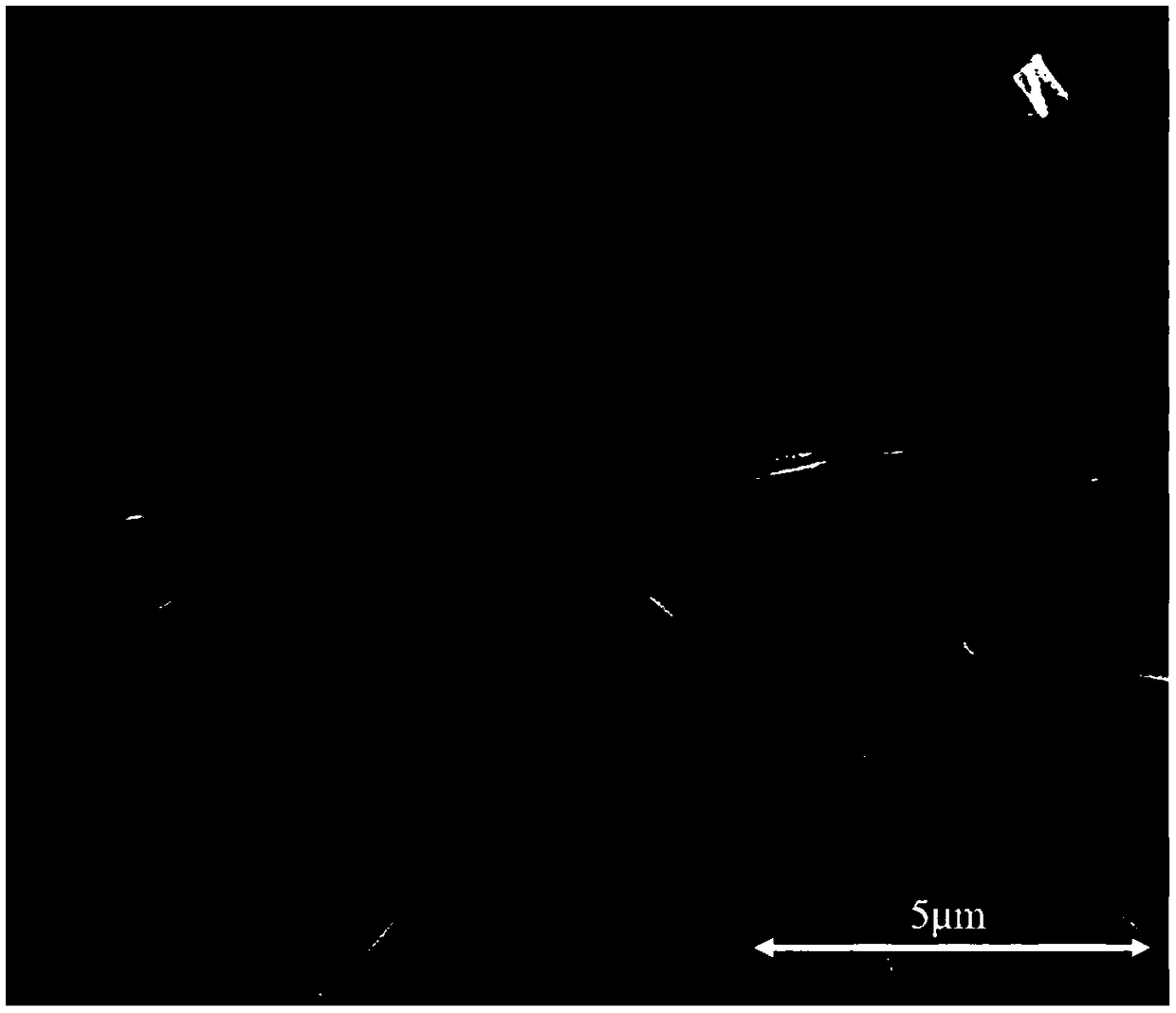

[0039] A preparation method of SiAlCN (O) ceramic nanofibers, comprising the following steps:

[0040] (1) Preparation of polyaluminosilazane

[0041] Repeatedly evacuate the Schlenk reaction bottle and fill it with high-purity argon for at least three times to ensure that the air and water in the bottle are completely discharged. Then add 100ml of anhydrous tetrahydrofuran with a syringe, and then add 15g of methylvinyldichlorosilane, methylhydrogen Dichlorosilane 0.5g, pass high-purity ammonia gas (purity 99.9999%) at 0°C for 2.5h and continue to react for 2h, then add 3.1g of octadecyl isocyanate to react overnight, and distill off the solvent under reduced pressure to obtain a viscous 12.5ml of a toluene solution of diisobutylaluminum hydride (the concentration of diisobutylaluminum hydride is 2M) was slowly added dropwise at 0°C to the liquid polysilazane, and added dropwise After completion, the temperature was raised to room temperature, reacted for 24 hours, and disti...

Embodiment 2

[0047] A preparation method of SiAlCN (O) ceramic nanofibers, comprising the following steps:

[0048] (1) Preparation of polyaluminosilazane

[0049]Repeatedly evacuate the Schlenk reaction bottle and fill it with high-purity argon for at least three times to ensure that the air and water in the bottle are completely discharged. Then add 100ml of anhydrous tetrahydrofuran with a syringe, and then add 11.12g of methylvinyldichlorosilane, methyl Hydrogen dichlorosilane 0.5g, pass through high-purity ammonia gas (purity 99.9999%) at 0°C for 2.5h after ammonolysis, then react for 2h under the protection of argon; add 8g of octadecyl isocyanate to react overnight, and remove by distillation under reduced pressure solvent, to obtain viscous liquid polysilazane; at 0°C, slowly dropwise add 12.5ml of a toluene solution of diisobutylaluminum hydride (the concentration of diisobutylaluminum hydride is 2M) to the liquid polysilazane After the dropwise addition, the temperature was rais...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com