A coal chemical wastewater treatment device

A technology of coal chemical wastewater and treatment device, which is applied in the directions of grease/oily substance/float removal device, separation method, liquid separation, etc., can solve problems such as difficult to be removed, and achieve the effect of ensuring oil scraping and cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

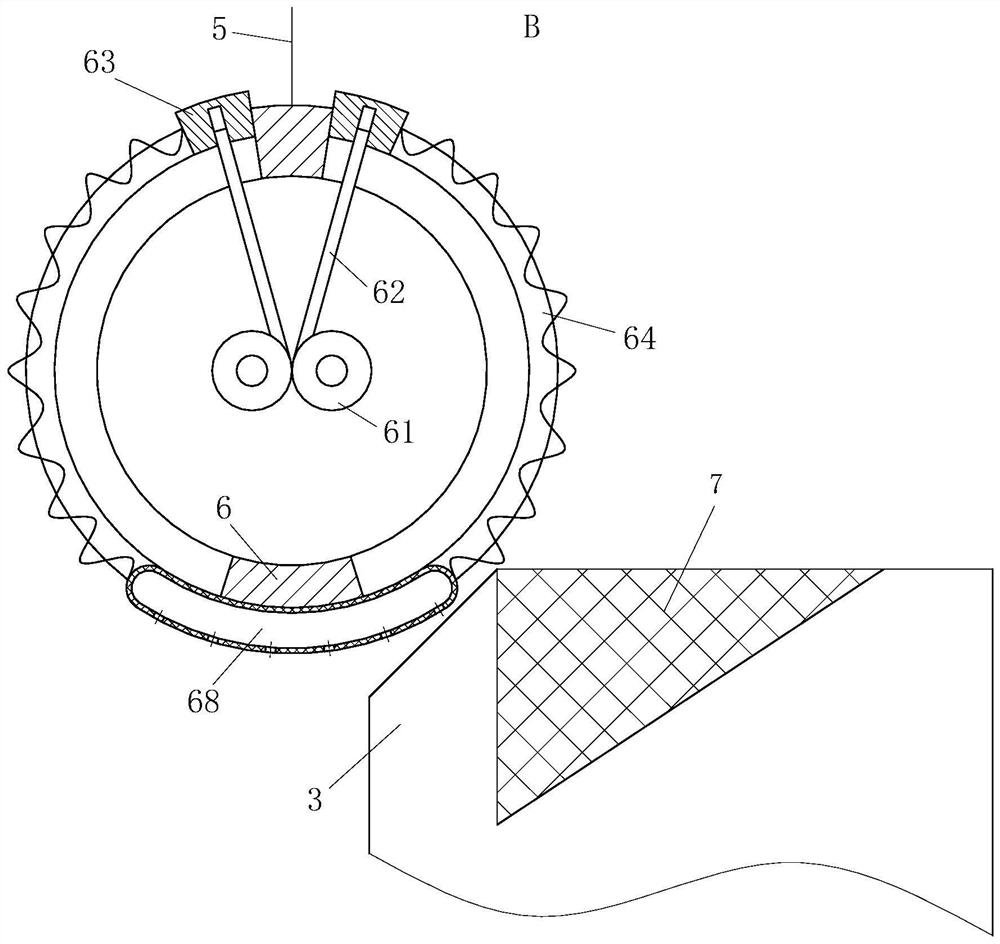

[0025] As a kind of embodiment of the present invention, the left end of described swing arc-shaped plate 65 is hinged a swing base 67; The bottom surface of described swing base 67 can fit completely with the surface of No. 2 magnet 63; During work, conveyor belt 4 will When the oil scraper rod 6 is driven to the rightmost end, the oil scraper rod 6 is lifted, and the No. 2 magnet 63 on the right side of the oil scraper rod 6 attracts the swing seat 67 at the left end of the swing arc plate 65, and the swing arc plate 65 passes through the swing seat 67 Drive the No. 2 magnet 63 to move along the annular chute 64, and the spring on the swing arc plate 65 is continuously compressed simultaneously, and the angle of the swing seat 67 at the end of the swing arc plate 65 is also constantly changing, ensuring the swing seat 67. The bottom surface is completely attached to the surface of the No. 2 magnet 63, thereby ensuring the reliability of attraction.

[0026] As an embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com