A mining explosion-proof electro-hydraulic brake valve

An electro-hydraulic braking, mine explosion-proof technology, applied in the direction of brakes, brake transmission devices, multi-way valves, etc., can solve the problems of difficult electrification control of braking systems, no explosion-proof function, and high labor intensity of workers. Reduce the labor intensity of workers, easy electrical control, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

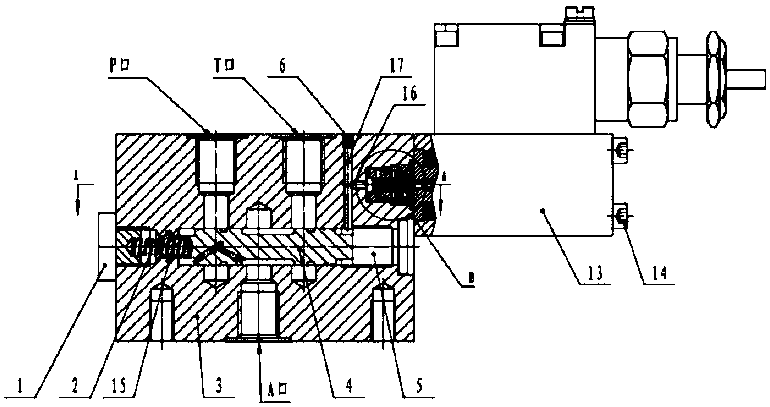

[0019] Such as figure 1 As shown, a mining explosion-proof electro-hydraulic brake valve includes a venting screw plug 1, a spring 2, a valve body 3, a valve core 4, a plug 5, a pilot valve core 7, a pilot valve sleeve 8, and a tower return spring 12 and an explosion-proof linear force motor 13, the valve body 3 is provided with A ports, P ports and T ports, and the valve body 3 is provided with an internal space for installing a valve core, and the internal space is provided with a valve core 4, and the The inner space is respectively connected with A port, P port and T port, one end of the valve core 4 is in contact with the plug 5, the other end of the valve core 4 is connected with the spring 2, the spring 2 is fixed on the venting screw plug 1, and the venting screw plug 1 is connected with the valve Body 3 threaded connection.

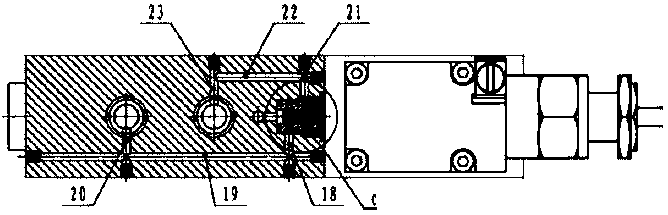

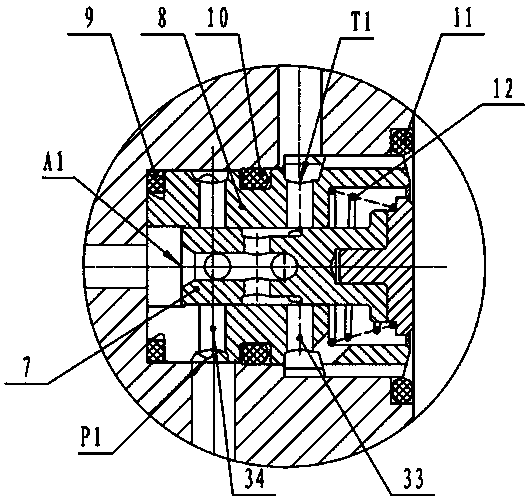

[0020] Such as image 3 , 4 As shown, the valve body 3 is also provided with a pilot valve sleeve 8, and a clearance fit is used between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com