Roughening-free construction method and mould for precast hollow slab girder

A hollow plate beam, chisel-free technology, applied in the direction of manufacturing tools, molds, unloading devices, etc., can solve the problems of easily destroying the plate beam structure, difficulty in manual or mechanical chiseling, uneven distribution of chiseling hair, etc. Gross process, shortening the casting and installation cycle of slab beams, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

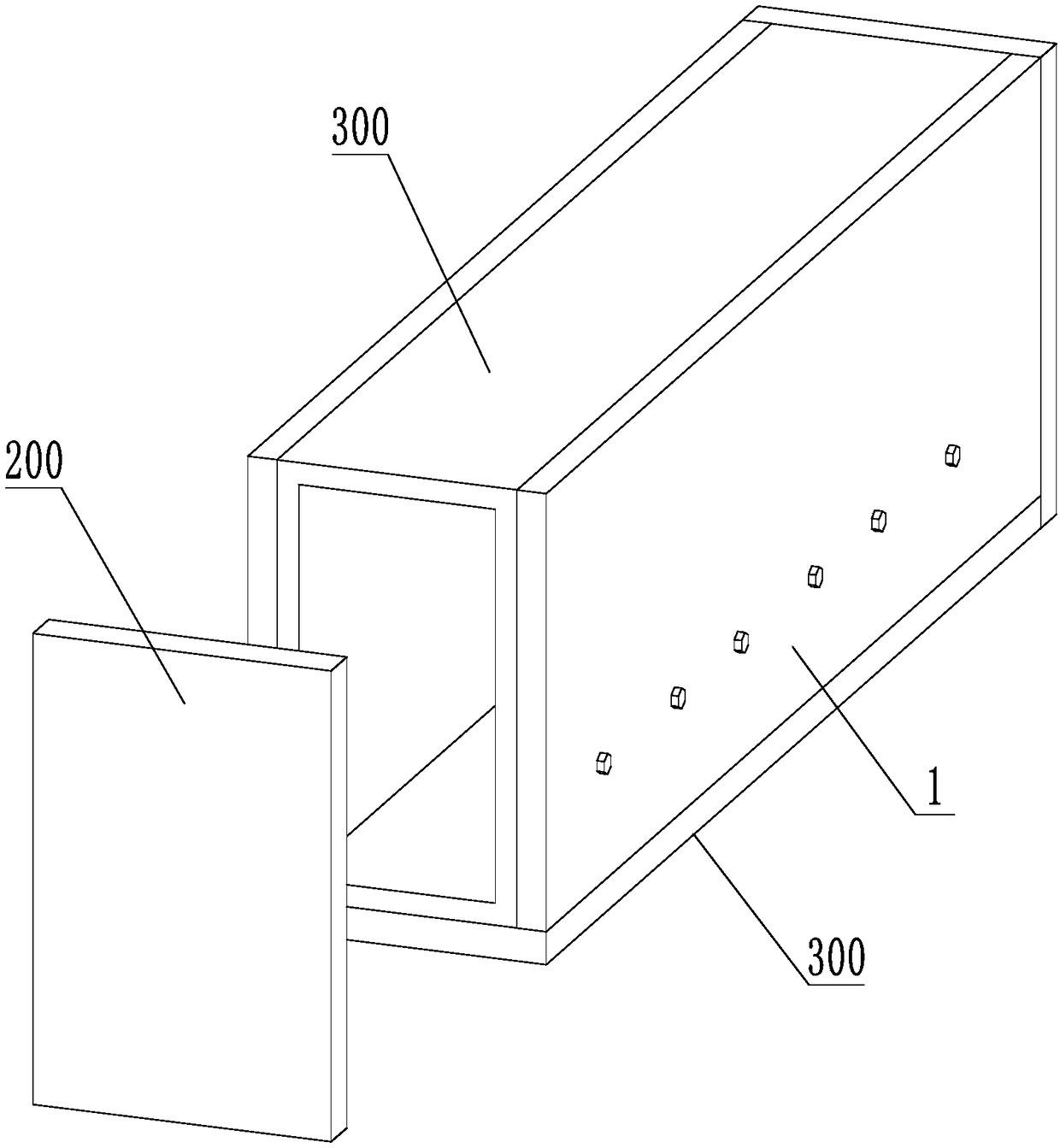

[0040] A prefabricated hollow slab beam free of chiseling construction mold, as attached figure 1 As shown, the mold is mainly composed of bottom formwork 100 at the bottom, end formwork 200 at both ends of the mold length direction, and side formwork 1 on both sides to form a mold with an upper opening. An inner mold is also arranged inside the plate girder 300 .

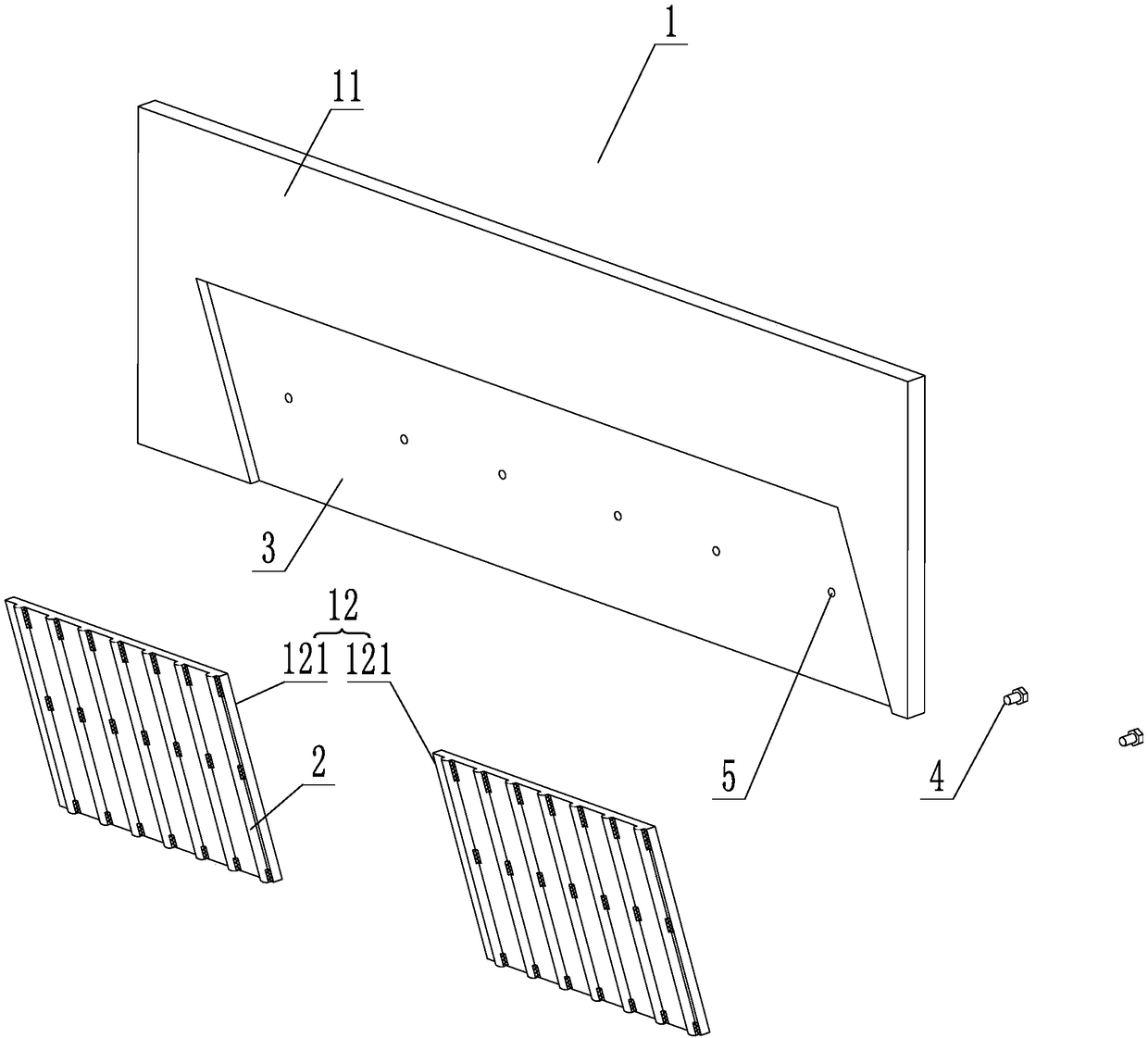

[0041] as attached figure 2 As shown, the side formwork 1 is formed by connecting the outer panel 11 and the inner lining panel 12, wherein the inner lining panel 12 is detachably connected to the inner side of the outer panel 11, which facilitates the disassembly and replacement of the inner lining panel 12. The outer plate 1 is a rectangular plate, and the lower part of its inner surface is provided with a parallelogram-shaped groove 3, the groove 3 extends along the length direction of the outer plate 11, and the inner lining plate 12 is composed of a plurality of single plates 121 of equal size. less than th...

Embodiment 2

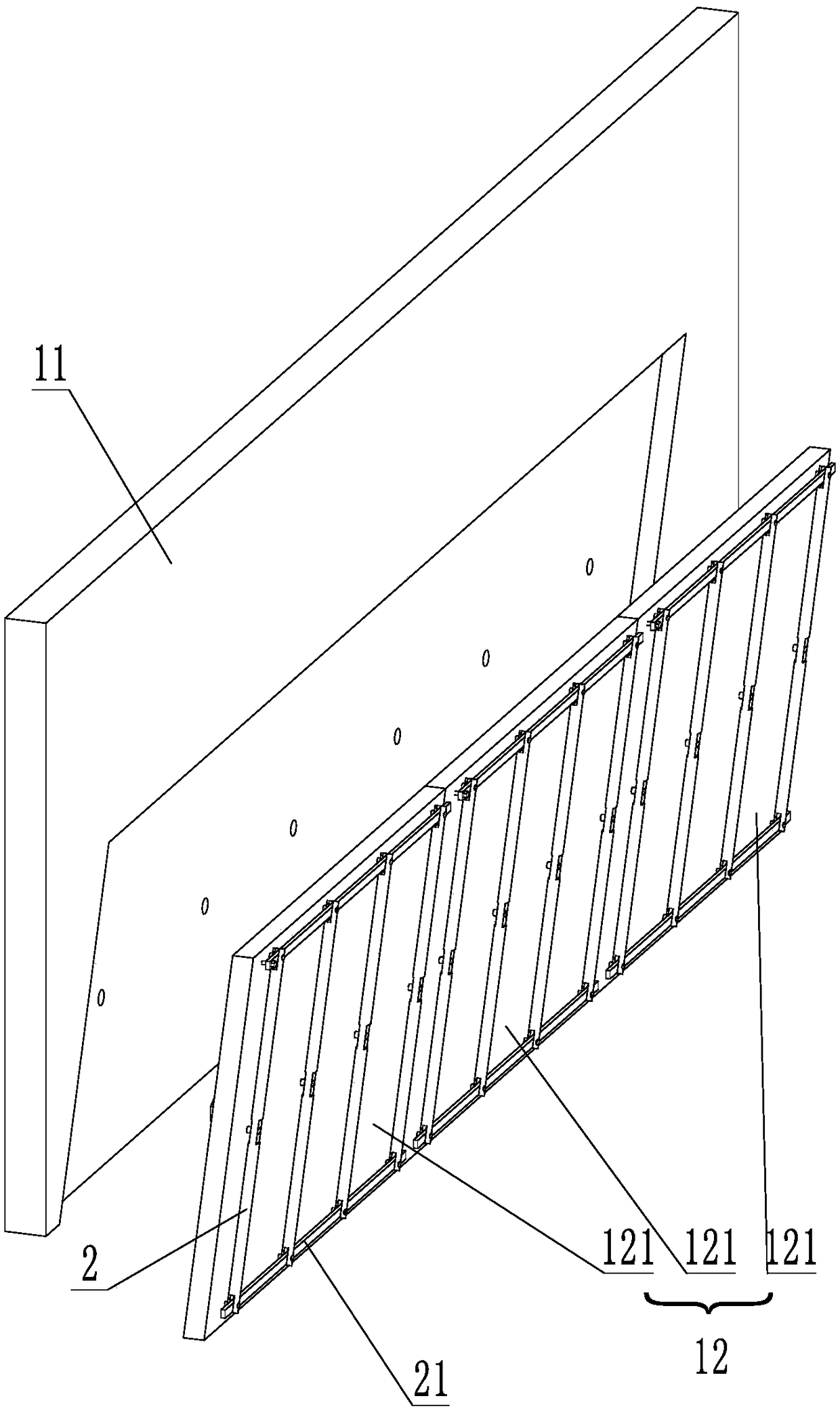

[0046] as attached image 3 and 4As shown, a plurality of ribs 2 are rotatably connected to the middle position of the inner surface of each single plate 121 of the inner liner 12, and the rotation axis of the ribs 2 is set in the middle of the ribs 2, and is located at the same position on the single plate 121. level height. In the present embodiment, the rib 2 adopts a plurality of equal-length metal rods, pointing to the upper and lower sides of the veneer 121, the length of the rib 2 is equal to the height of the veneer 121, and the rib 2 rotates, so that the upper and lower ends of the rib 2 will not move from the single plate 121. The upper and lower sides of the plate 121 protrude; the convex ribs 2 are equally spaced on the single plate 121, and the distance between the rotation axes of adjacent convex ribs 2 is 100mm.

[0047] The upper and lower ends of the ribs 2 on each veneer 121 are hinged with a connecting rod 21, and the connecting rod 21 is hinged with all t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com