A Control Method for Precise Forming of Laser Cladding Thin-walled Parts Based on Temperature Prediction

A technology of laser cladding and control method, which is applied in the directions of additive manufacturing, process efficiency improvement, coating, etc., can solve the problems of unstable thin wall thickness, etc., and achieve the effect of stable thickness and stable height increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0021] The method of this embodiment is as follows:

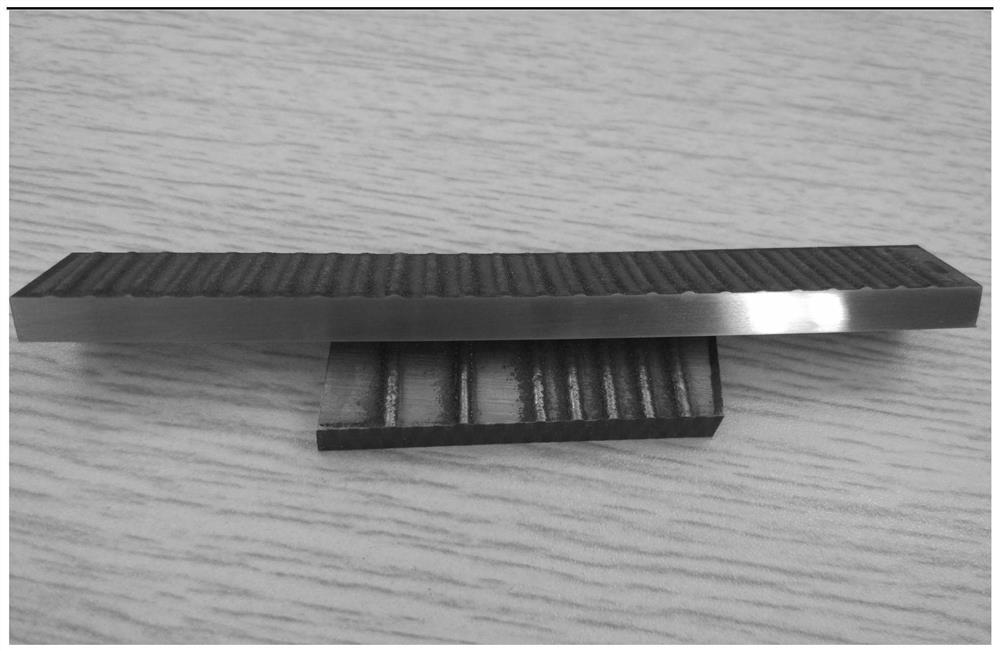

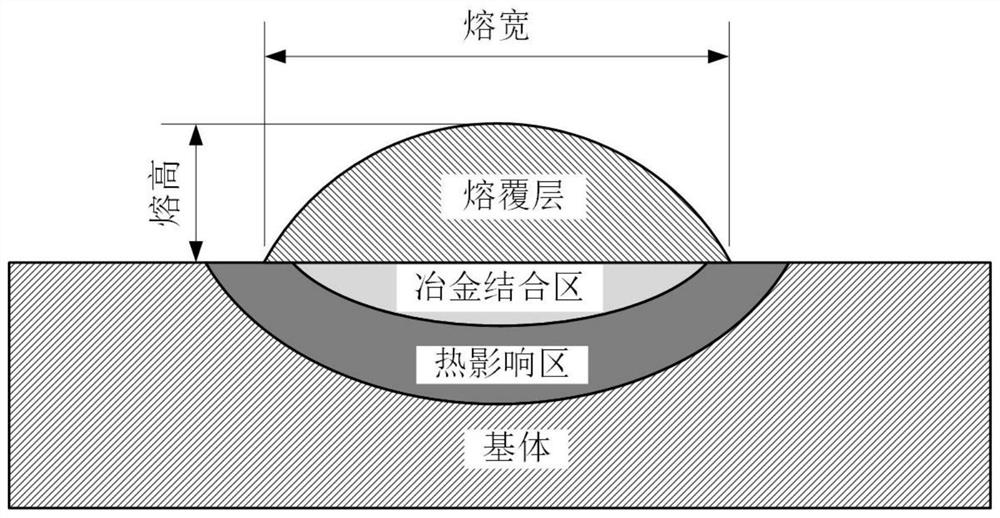

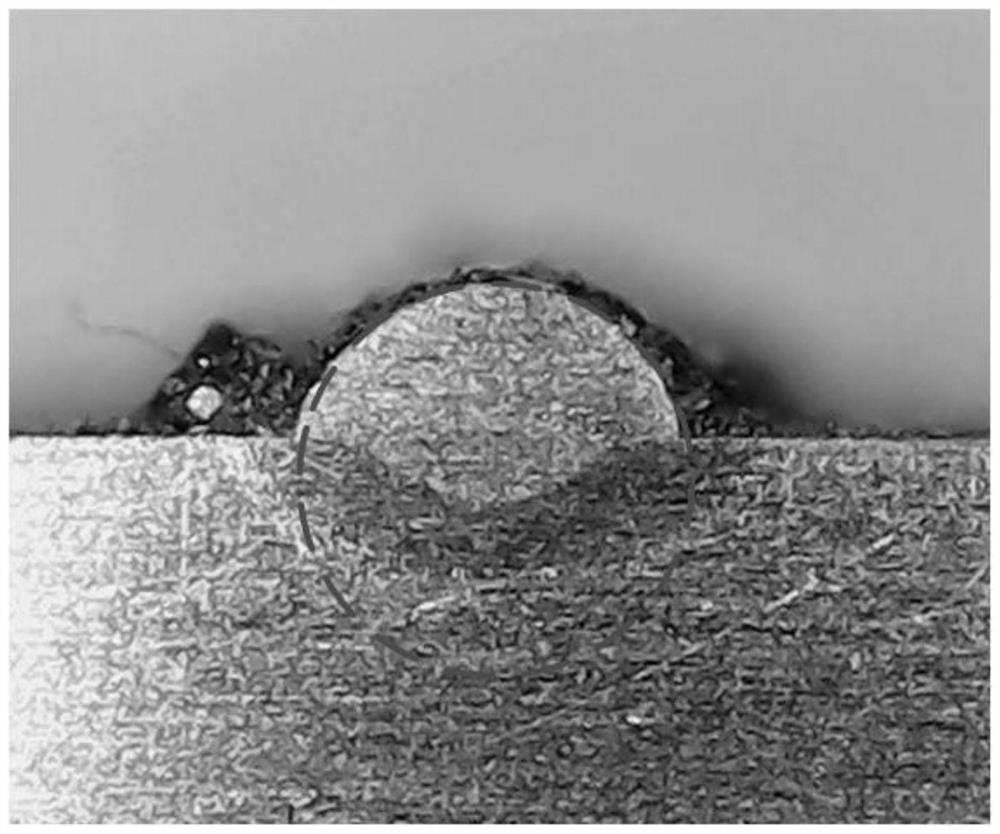

[0022] Step 1: According to the response surface method, conduct a single-pass cladding experiment, and obtain the regression model of the influence of powder feeding speed, scanning speed, laser power and substrate temperature on the parameters of the single-pass cladding layer, such as melting width, melting height and aspect ratio;

[0023] The equipment used in the examples includes a KUKA robotic arm, a coaxial powder feeding laser head, a fiber laser and a turntable powder feeder. These devices have established a communication relationship with the KUKA robot control cabinet, and these devices can be called throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com