Ceramsite precoated sand and preparation method thereof

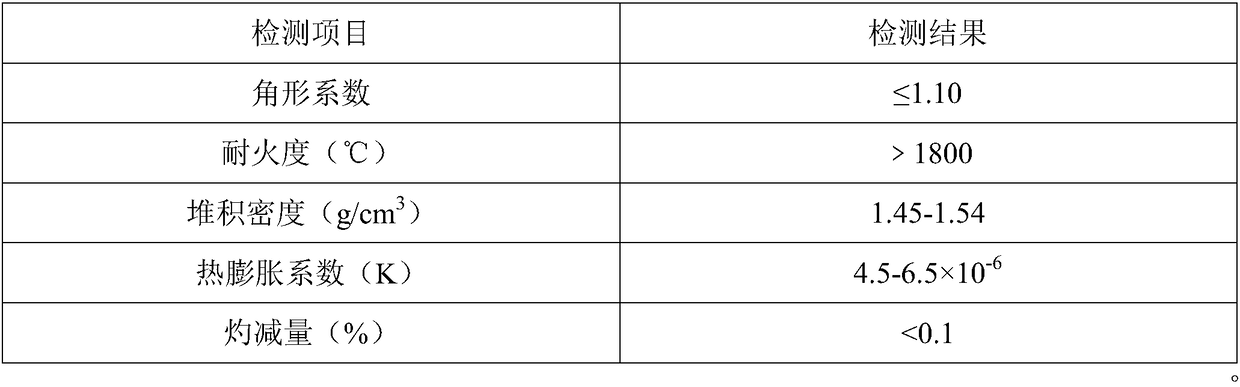

A technology of coated sand and ceramsite sand, applied in the field of foundry materials, can solve the problems of poor fluidity, damage to metallurgical quality of castings, large thermal expansion, etc., and achieve strong fluidity and permeability, good comprehensive casting performance, strong high temperature resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The ceramsite coated sand in this embodiment is prepared according to the following steps:

[0044] (1) Weighing of raw materials: Weigh each raw material according to the amount in Table 2;

[0045] (2) Raw sand heating: The raw sand is sent to the batch heating machine with a bucket elevator and heated to 125°C;

[0046] (3) Sand mixing and coating: Phenolic resin, coupling agent, curing agent, high temperature resistant auxiliary agent, lubricant are sequentially added to the heated raw sand, and after mixing uniformly, coarse sand is obtained;

[0047] (4) Screening and cooling: the coarse sand obtained in step (3) is screened to remove impurities above 30 mesh and below 200 mesh, and then the temperature is lowered to 50° C. to obtain the ceramsite coated sand of this embodiment.

[0048] Specifically in step (3), first add phenolic resin to the heated raw sand and stir, stir evenly to form a resin coating on the surface of the ceramsite sand, then add the coupling agent and...

Embodiment 2

[0051] The ceramsite coated sand in this embodiment is prepared according to the following steps:

[0052] (1) Weighing of raw materials: Weigh each raw material according to the amount in Table 2;

[0053] (2) Raw sand heating: send the raw sand to the batch heating machine with a bucket elevator and heat up to 135℃;

[0054] (3) Sand mixing and coating: Phenolic resin, coupling agent, curing agent, high temperature resistant auxiliary agent, lubricant are sequentially added to the heated raw sand, and after mixing uniformly, coarse sand is obtained;

[0055] (4) Screening and cooling: the coarse sand obtained in step (3) is screened to remove impurities above 30 mesh and below 200 mesh, and then the temperature is lowered to 40° C. to obtain the ceramsite coated sand of this embodiment.

[0056] Specifically in step (3), first add phenolic resin to the heated raw sand and stir, stir evenly to form a resin coating on the surface of the ceramsite sand, then add the coupling agent and cu...

Embodiment 3

[0058] The ceramsite coated sand in this embodiment is prepared according to the following steps:

[0059] (1) Weighing of raw materials: Weigh each raw material according to the amount in Table 2;

[0060] (2) Raw sand heating: the raw sand is sent to the batch heating machine with a bucket elevator and heated to 130℃;

[0061] (3) Sand mixing and coating: Phenolic resin, coupling agent, curing agent, high temperature resistant auxiliary agent, lubricant are sequentially added to the heated raw sand, and after mixing uniformly, coarse sand is obtained;

[0062] (4) Screening and cooling: the coarse sand obtained in step (3) is screened to remove impurities above 30 mesh and below 200 mesh, and then the temperature is lowered to 30° C. to obtain the ceramsite coated sand of this embodiment.

[0063] Specifically in step (3), first add phenolic resin to the heated raw sand and stir, stir evenly to form a resin coating on the surface of the ceramsite sand, then add the coupling agent and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com