Label removal device of plastic bottle

A technology for plastic bottles and labels, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low efficiency, time-consuming and labor-intensive label removal methods, and achieves reasonable and novel design, convenient operation and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

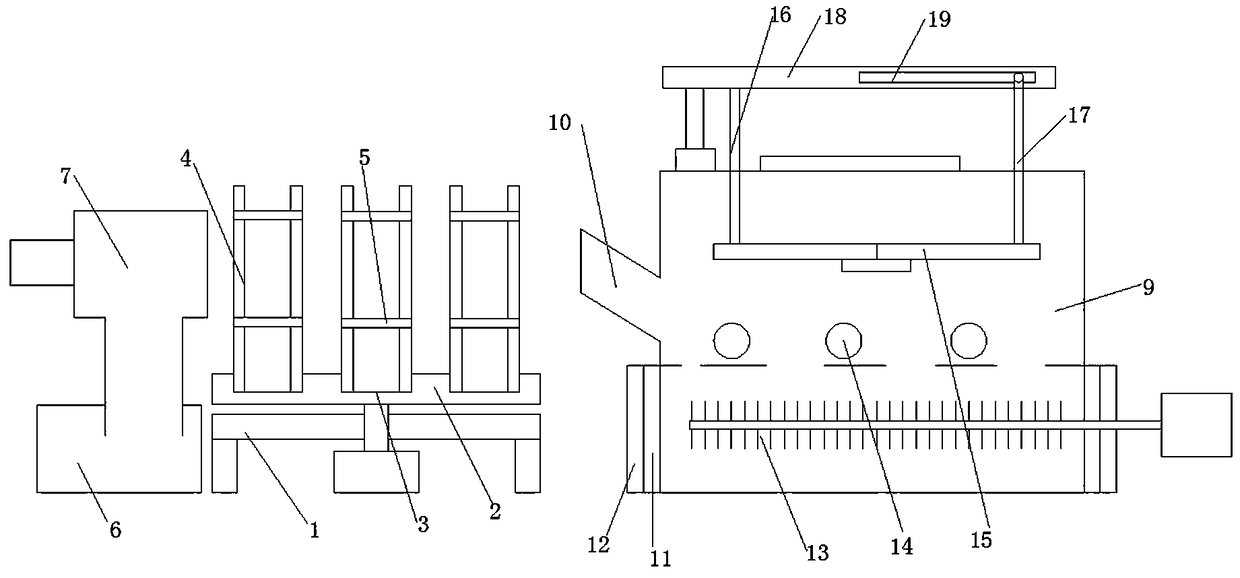

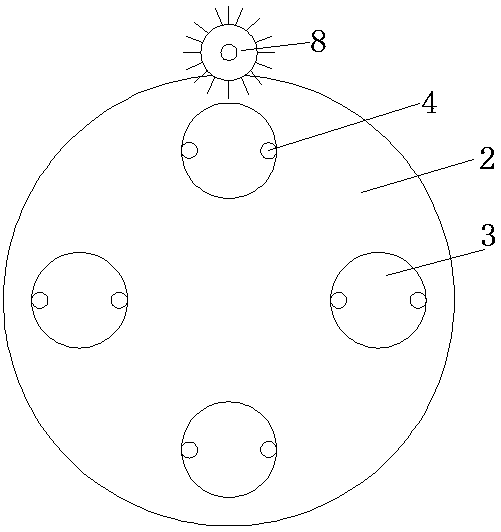

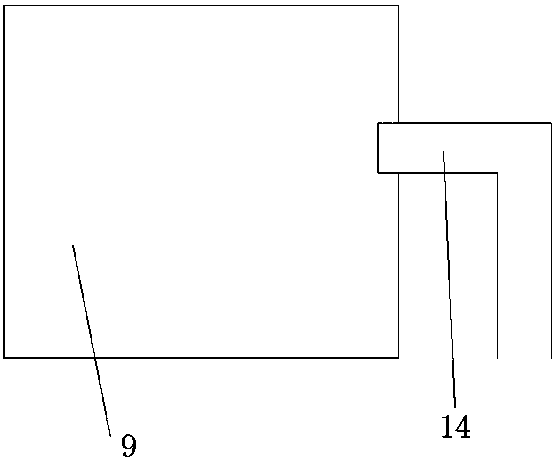

[0016] Such as Figure 1-3 As shown, the present invention is a plastic bottle label removal device, including a support base 1, a rotating base 2 driven by a motor is arranged above the supporting base 1, and several grooves 3 are arranged on the rotating base 2 , preferably, the number of grooves is four, which are symmetrically arranged in pairs, and support frames 4 are also provided on the left and right sides above each of the grooves 3, and limit stops are respectively set above and below the two support frames 4 Circle 5, the plastic bottle is placed in the support frame and is limited by the limit circle, and the position of the label is leaked. On the rear side of the rotating base 2, there is also a needle roller 8 driven by a motor to rotate. In the process of rotation, it contacts with the label of the plastic bottle to achieve the purpose of piercing the label. The rotation speed of the needle roller is greater than that of the rotating base. In this way, the nee...

Embodiment 2

[0018] Such as Figure 4 As shown, the present invention is a plastic bottle label removal device, comprising a support base 1, a rotating base 2 driven by a motor is arranged above the supporting base 1, and several Groove 3, preferably, the number of grooves is four, symmetrically arranged in pairs, support frames 4 are also arranged on the left and right sides above each of the grooves 3, and above and below the two support frames 4 respectively Set the limit ring 5, place the plastic bottle in the support frame and limit the position through the limit ring, and leak the position of the label. On the rear side of the rotating base 2, there is also a needle roller 8 driven by a motor to rotate on the needle roller The piercing needles are in contact with the label of the plastic bottle during the rotation, which can achieve the purpose of piercing the label. The rotation speed of the needle roller is greater than the rotation speed of the rotating base. In this way, the need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com