One-step preparation of biocompatible oil-core microcapsules and its application

A biocompatible, step-by-step technology, applied in the field of one-step preparation of biocompatible oil core microcapsules, can solve the problems of difficulty in mass production and long time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

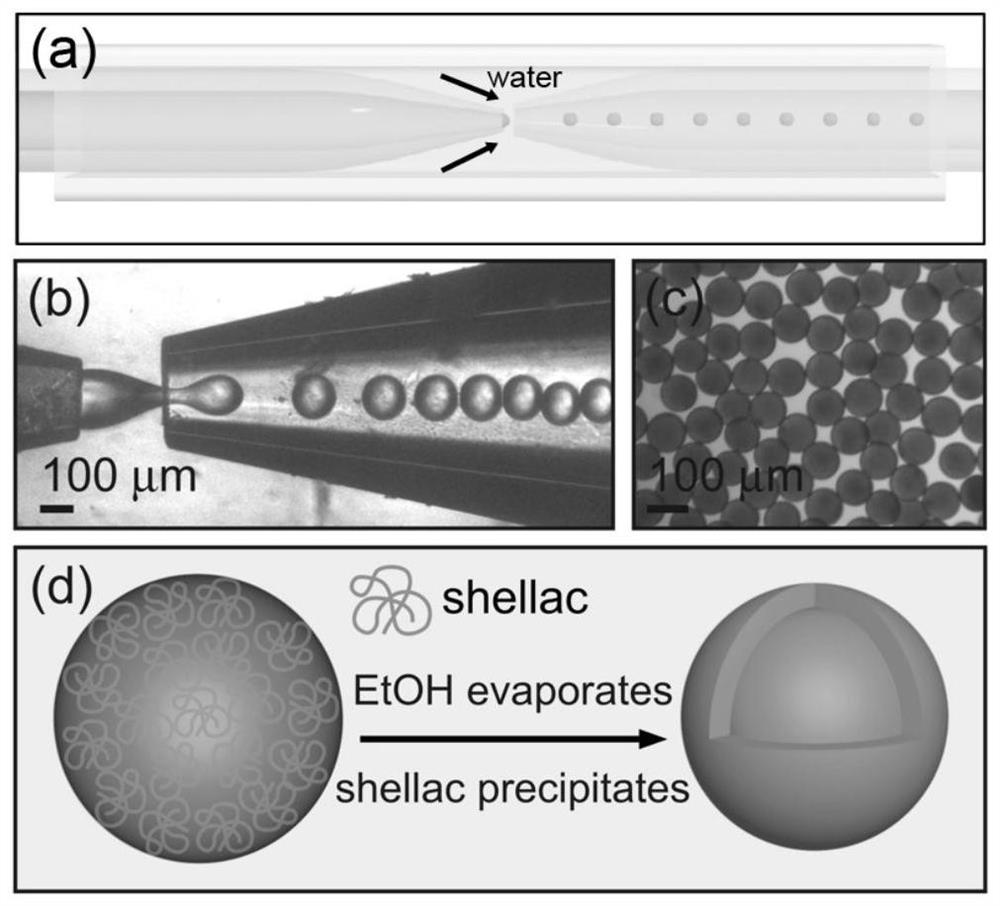

[0043] Example 1: Preparation of oil-core microcapsules with uniform size and diameter of about 89 μm

[0044] Refer to attached figure 1 , using the method of the present invention to prepare biocompatible oil-core microcapsules, the specific steps are as follows: (1) Fabrication of the microfluidic device: prepare two circular glass capillaries and one square glass capillary. Ultrasonic cleaning of the above-mentioned glass capillary and drying; using an extensometer to process one end of the circular glass capillary into a tapered shape; rubbing the pointed end of the circular glass capillary with sandpaper to make the port flat; Insert one end of the pointed cone from both ends of the square glass capillary respectively, and center the pointed ends of two round glass capillaries in the square glass capillary, and then fix all the above-mentioned glass capillaries on the glass slide with glue. Capillary glass tube microfluidic device as attached figure 1 As shown, there i...

Embodiment 2

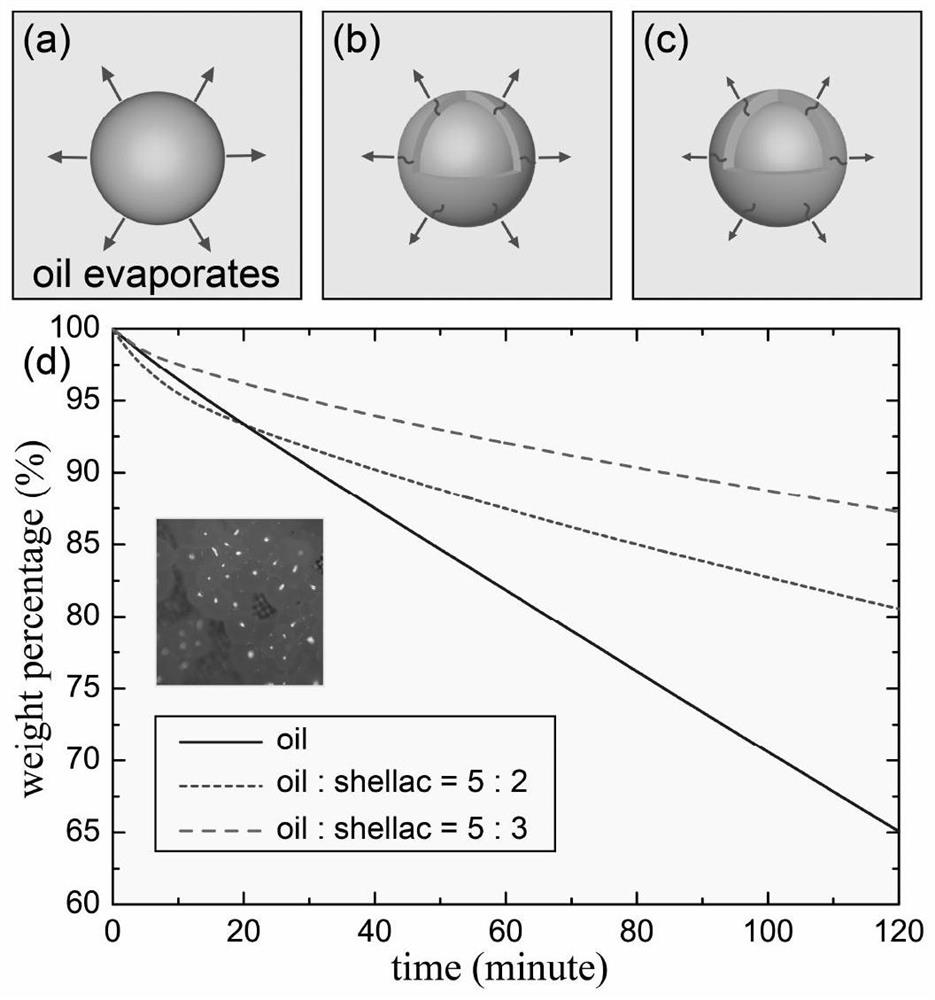

[0048] Example 2: Diffusion rate of oily substance wrapped in oil-core microcapsules as a function of wall thickness.

[0049] (1) 2ml dehydrated alcohol and 5ml lavender essential oil are mixed, then the shellac of 800mg is dissolved in the mixed solution, and this solution is used as new internal phase, and the oil nucleus microcapsule that wraps oily substance is prepared according to embodiment 1;

[0050] (2) 3ml dehydrated alcohol and 5ml lavender essential oil are mixed, then the shellac of 1200mg is dissolved in the mixed solution, and this solution is used as the new internal phase, and the oil nucleus microcapsule that wraps oily substance is prepared according to embodiment 1;

[0051] (3) The wrapped oily substance microcapsules prepared by (1) and (2) are cleaned three times with deionized water, then filtered with a filter screen, and the moisture on the surface of the microcapsules is removed to obtain surface-dried oil core microcapsules ( as attached figure ...

Embodiment 3

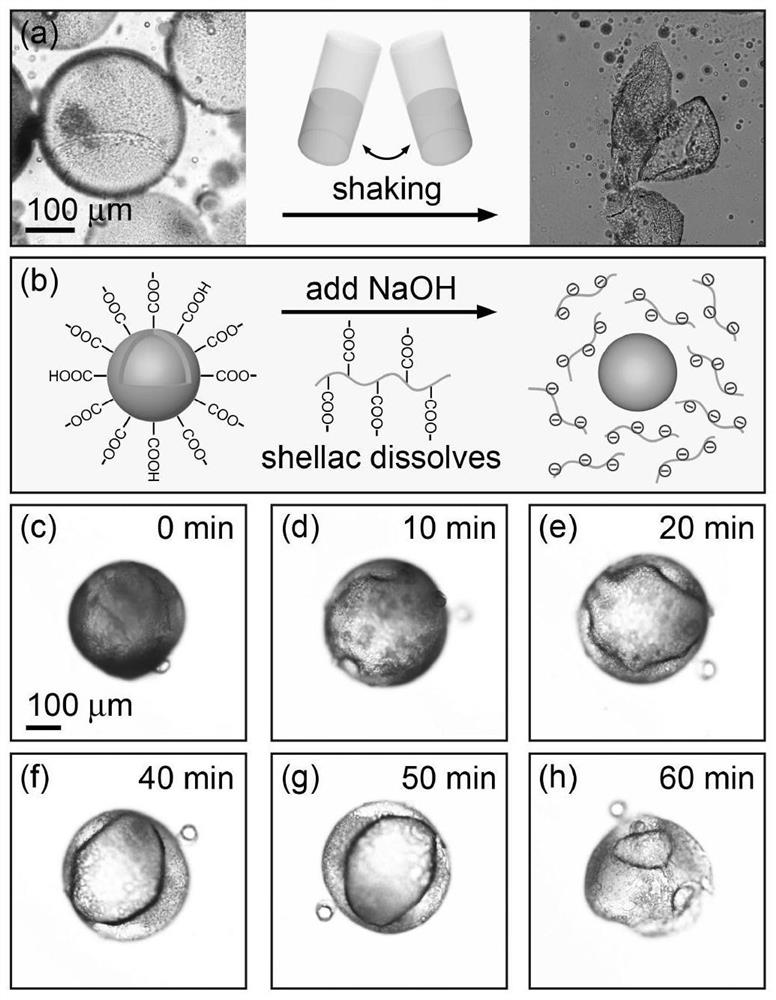

[0053] Example 3: Oil core microcapsules achieve sudden release of microcapsules by shaking

[0054] (1) 1ml dehydrated alcohol and 5ml lavender essential oil are mixed, then the shellac of 100mg is dissolved in the mixing solution, obtains internal phase, this solution is used as new internal phase, prepares the oil nucleus that obtains wrapping oil substance by embodiment 1 Microcapsules;

[0055] (2) Prepare oil core microcapsules according to (1) in Example 2, and wash it three times with deionized water;

[0056] (3) Disperse the microcapsules in deionized water, then place them in a test tube, and shake them back and forth to realize the rapid release of the encapsulated oily substance from the microcapsules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com