Method of ultraviolet-introducing oxidization of undaria pinnatifida polyphenol for enhancing gel property

A technology of polyphenol oxidation and wakame, applied in the direction of food science, etc., to achieve the effect of improving gel strength, facilitating industrial production, improving elasticity and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

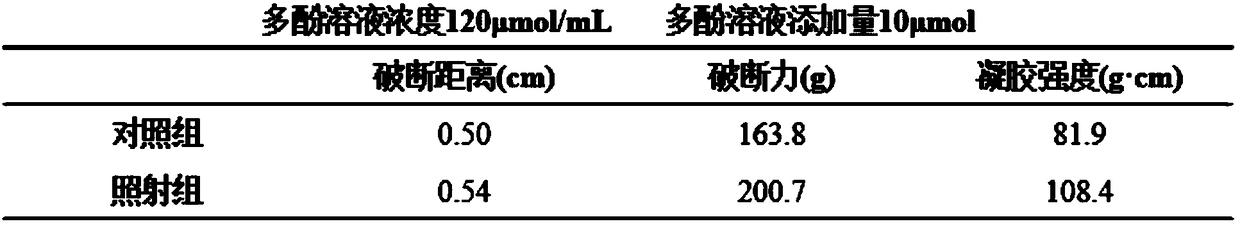

Embodiment 1

[0044] Thaw the chilled Spanish mackerel, remove the head, tail and viscera, and collect the meat in an ice bath, and collect 20g of fish meat for beating. Add 10 μmol of wakame sporophyll polyphenol solution with a concentration of 120 μmol / mL to 20 g of fish pulp and continue homogenization and mixing. After the obtained fish meat is evenly coated on the petri dish, it is irradiated with ultraviolet light for 1.5h, and the irradiation intensity is 0.8W / m 2 . After refrigerating and standing for 14 hours, fish sausages with a diameter of 15 mm were made. Then, it was heated in a water bath at a heating temperature of 80° C. and a heating time of 8 minutes to make it gel. The heat-treated samples were immediately stored in an ice bath for 40 min, and the gel strength was tested after equilibrating at 27 °C for 2 h. The breaking distance of fish sausage products without UVA irradiation was 0.50cm, and the gel strength was 81.9g·cm; the breaking distance of fish sausage produ...

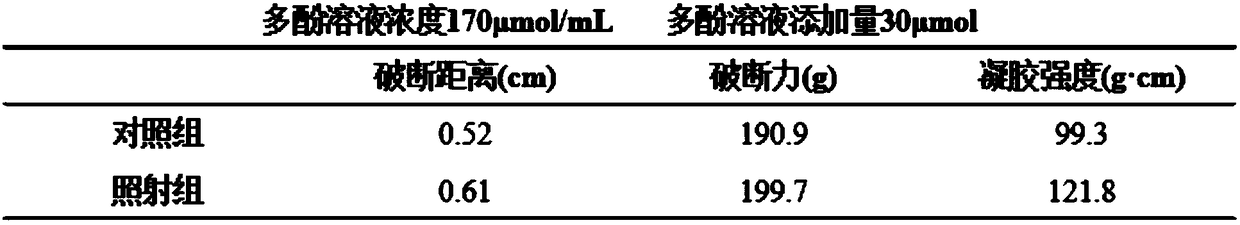

Embodiment 2

[0048] Thaw the chilled Spanish mackerel, remove the head, tail and viscera, and collect the meat in an ice bath, and collect 30g of fish meat for beating. Add 30 μmol of wakame sporophyll polyphenol solution with a concentration of 170 μmol / mL to 30 g of fish pulp and continue homogenization and mixing. After the obtained fish meat is flat-coated on a petri dish, it is irradiated with ultraviolet rays for 3 hours, and the irradiation intensity is 1.0W / m 2 . After refrigerating and standing for 15 hours, fish sausages with a diameter of 15 mm were made. Then, it was heated in a water bath at a heating temperature of 95° C. and a heating time of 20 minutes to make it gel. The heat-treated samples were immediately stored in an ice bath for 30 min, and the gel strength was tested after equilibrating at 25 °C for 4 h. The breaking distance of fish sausage products without UVA irradiation was 0.52cm, and the gel strength was 99.3g·cm; the breaking distance of fish sausage produc...

Embodiment 3

[0052] Thaw the chilled Spanish mackerel, remove the head, tail and viscera, and collect the meat in an ice bath, and collect 40g of fish meat for beating. Add 120 μmol of wakame sporophyll polyphenol solution with a concentration of 150 μmol / mL to 40 g of fish pulp and continue homogenization and mixing. After the obtained fish meat is flat-coated on a petri dish, it is irradiated with ultraviolet rays for 2 hours, and the irradiation intensity is 1.2W / m 2 . After refrigerating and standing for 18 hours, fish sausages with a diameter of 15 mm were made. Then heat in a water bath, the heating temperature is 65°C, and the heating time is 25 minutes to make it gel. The heat-treated samples were immediately stored in an ice bath for 35 minutes, and the gel strength was tested after equilibrating at 28°C for 2 hours. The breaking distance of fish sausage products without UVA irradiation was 0.60 cm, and the gel strength was 104.2 g cm; the breaking distance of fish sausage prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Gel strength | aaaaa | aaaaa |

| Gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com