Beta-glucan-enriched fermented feed and preparation method thereof,

A technology for fermenting feed and glucan, applied in animal feed, animal feed, additional food elements, etc., can solve the problem of limited beta-glucan, and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Add 500 kg of tap water, 3 kg of bacillus, and 5 kg of urea per ton of soybean molasses, stir intermittently after mixing, ferment for more than 15 days, and use it after the pH drops to 4.5.

[0031] (2) prepare bran, add above-mentioned fermented soybean molasses by every ton and be 1000 kilograms, mix and stir;

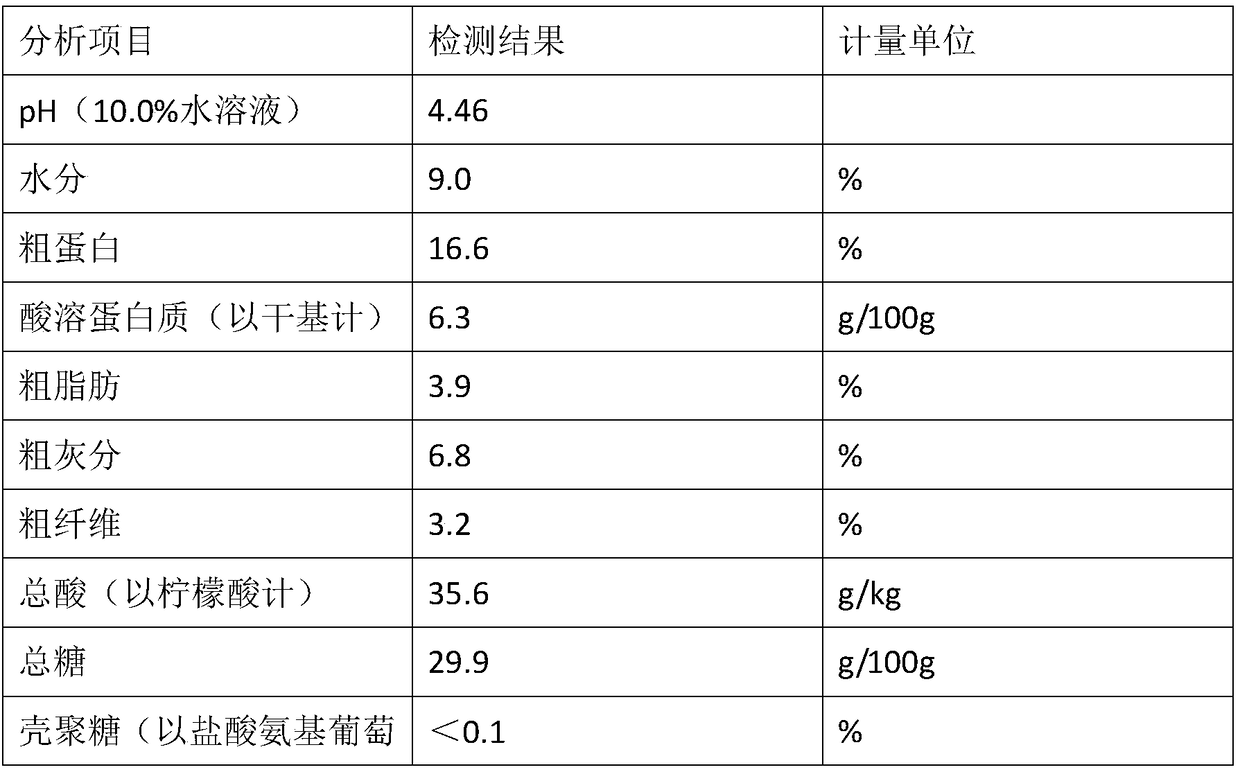

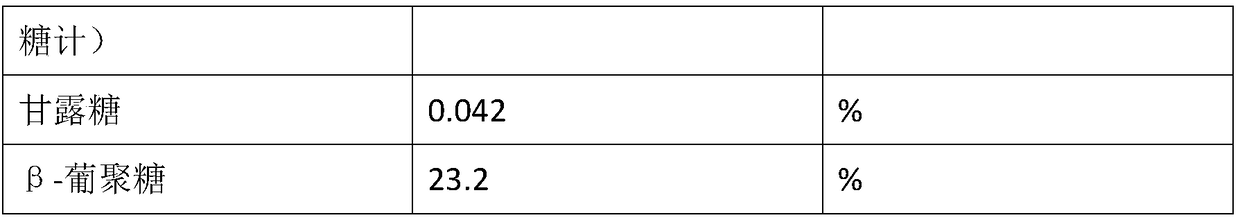

[0032] (3) The mixture is fermented until the material temperature reaches 50 degrees Celsius, then fermented for 20 hours, dried and crushed to obtain a dry fermented feed. The product testing index is shown in Table 1, wherein the content of β-glucan is as high as 23.2%.

[0033] Table 1.

[0034]

[0035]

Embodiment 2

[0037] According to requirements, add 500 kilograms of fermented soybean molasses per ton of dry fermented feed prepared in Example 1, mix evenly, subpackage after 24 hours of fermentation at normal temperature to obtain wet fermented feed.

Embodiment 3

[0039] (1) For each ton of soybean molasses, add 500 kg of tap water, 1 kg of bacillus, and 3 kg of urea, stir intermittently after mixing, ferment for more than 15 days, and use it after the pH drops to 4.5.

[0040] (2) prepare bran, add 300 kilograms of above-mentioned fermented soybean molasses by every ton, mix and stir;

[0041] (3) The mixture is fermented until the material temperature reaches 55 degrees Celsius, then fermented for 10 hours, dried and crushed to obtain a dry fermented feed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com