IDC peeling-free wire connection mechanism

A stripping-free and wire-free technology, applied in the direction of connection, conductive connection, clamping/spring connection, etc., can solve the problem of large wire diameter and large operating force of stripping-free connection, avoid adverse effects, facilitate processing, and improve strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

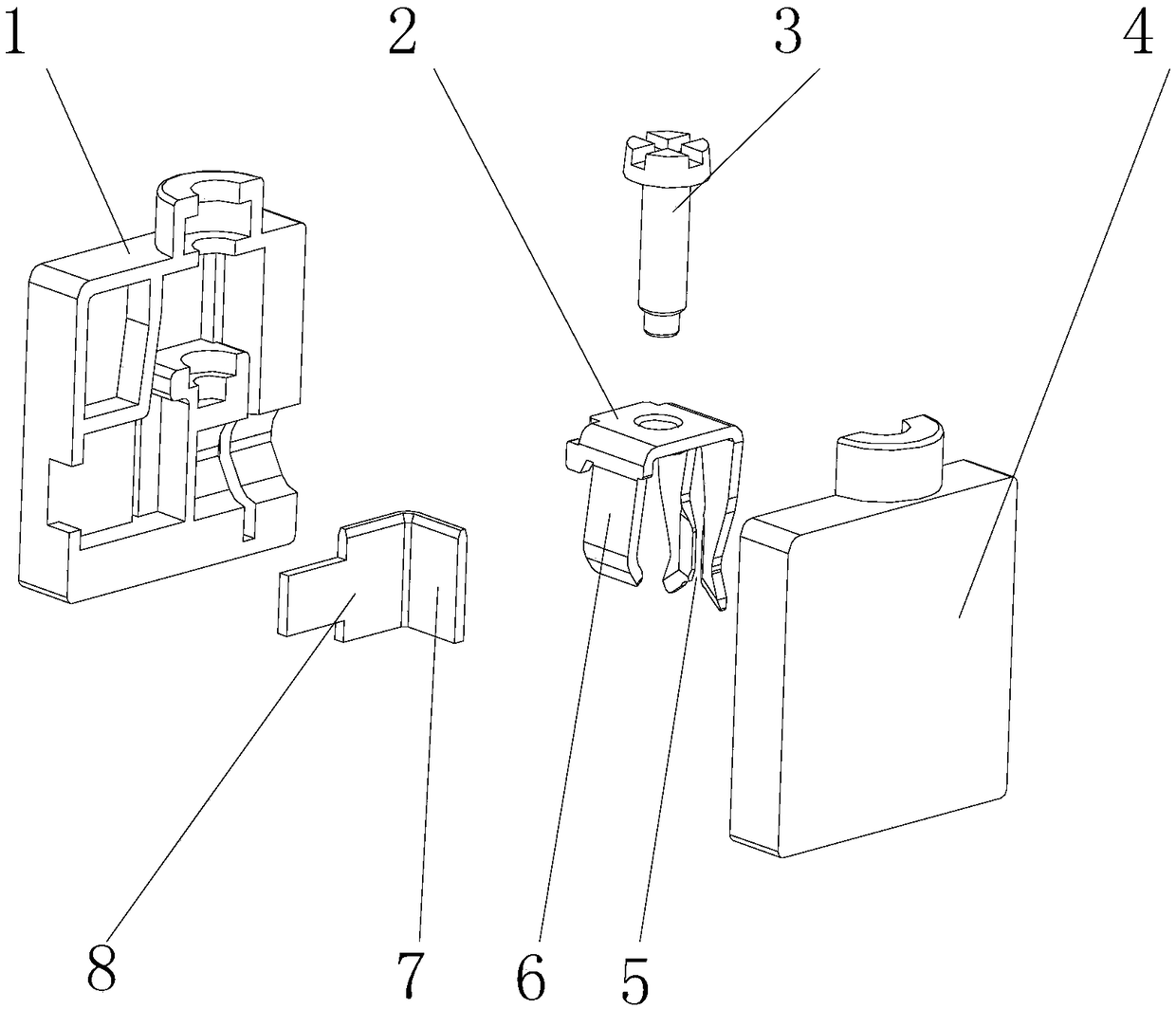

[0039] Example 1: See Figure 1-Figure 3 , the first technical solution of the present invention is: an IDC non-stripping wire connection mechanism, including a mounting shell, a switch knife conductive strip, an external conductive strip and a driver;

[0040] The installation shell is a rectangular shell structure, which is composed of a first right shell 1 and a first left shell 4 installed in one;

[0041] The external conductive strips include lath-shaped flat conductive strips 8 and side-plate conductive strips 7, and the side-plate conductive strips 7 are vertically attached to the sides of the flat conductive strips 8;

[0042] Described switch blade conductive strip is the semi-frame structure of bottom surface opening, comprises lath-shaped top surface conductive strip 2 and is connected to the shrapnel conductive strip 6 of top surface conductive strip 2 both sides and knife edge 5; Described knife edge 5 is made of two The block conductive strips are combined into...

Embodiment 2

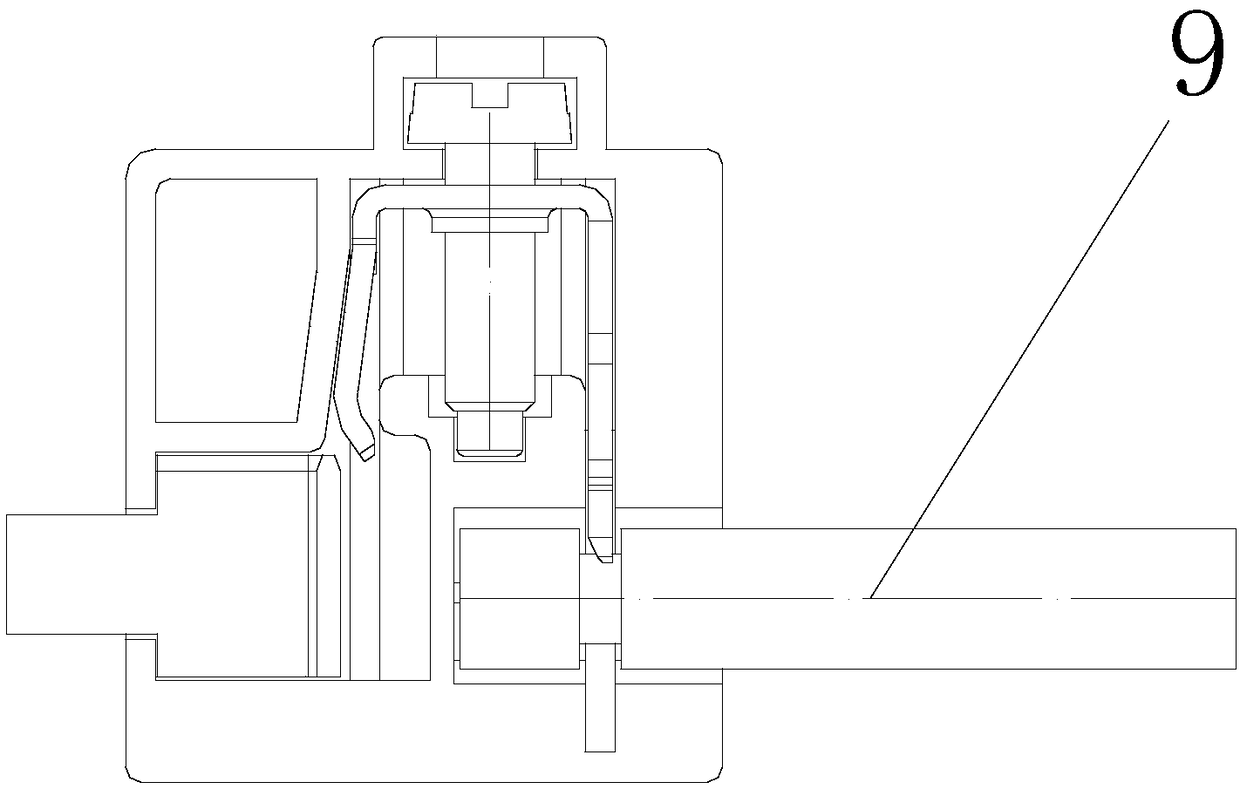

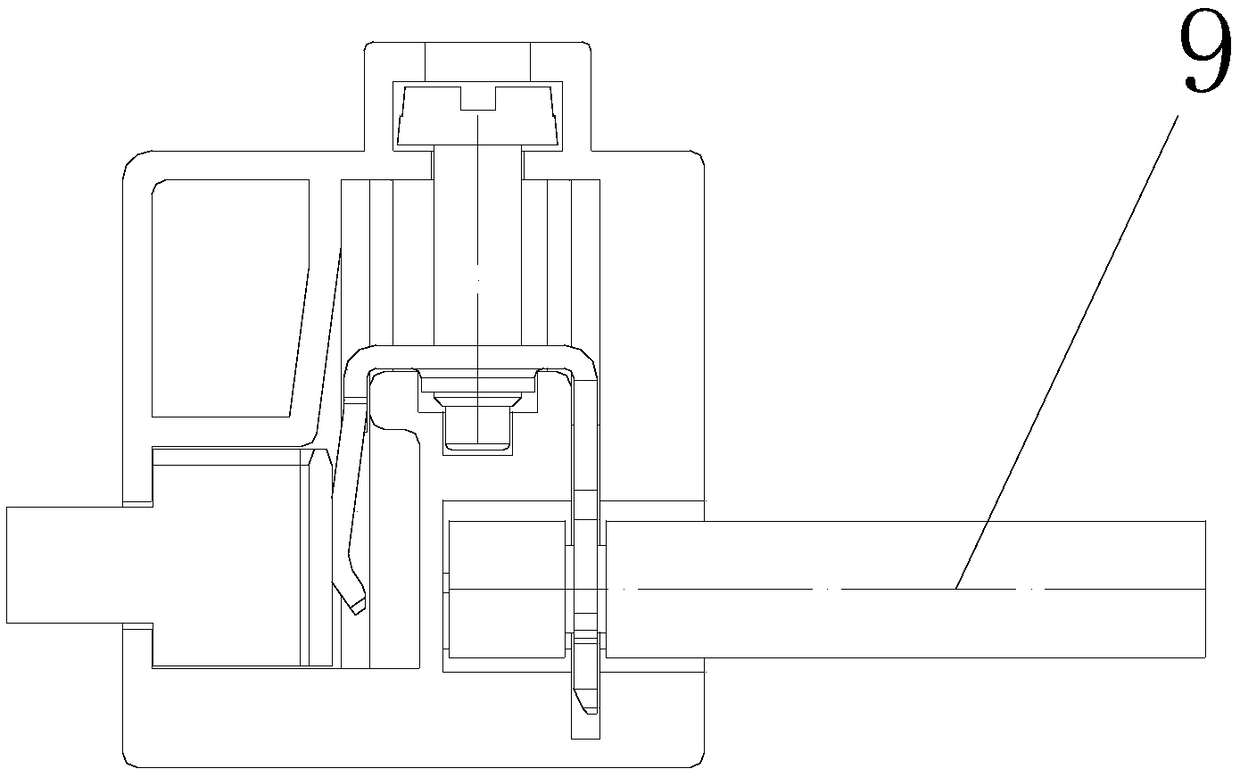

[0051] Example 2: see Figure 4-Figure 6, the difference between the second technical solution of the present invention and the first technical solution is that the switch knife conductive strip is different from the external conductive strip, that is: the switch knife conductive strip is a semi-frame structure with an opening on the bottom surface, including a strip-shaped The top surface conductive strip 2 and the straight conductive strip 10 and the knife edge 5 connected to the two sides of the top surface conductive strip 2; the knife edge 5 is composed of two conductive strips into a figure-eight structure, and is vertically fixed to the top surface conductive strip 2; the flat conductive strip 10 is vertically fixed to the lower end of the top conductive strip 2;

[0052] The external conductive strip includes a flat conductive strip 8 and a U-shaped shrapnel conductive strip 11 fixedly connected to the flat conductive strip 8, and the opening end of the U-shaped elasti...

Embodiment 3

[0055] Example 3: See Figure 7-Figure 10 The difference between the third technical solution of the present invention and the first technical solution is that it also includes an inner casing and a nut 12; the inner casing is a rectangular casing structure, and the second right casing 13 installed in one Composed of the second left casing 14; the inner casing can be reciprocated up and down and installed on the upper part of the installation casing;

[0056] The switch knife conductive strip is fixedly installed at the inner lower end of the inner casing, and the shrapnel conductive strip 6 and the knife edge 5 are exposed on the lower side of the inner casing;

[0057] The screw 3 is rotatably installed on the inner upper end of the inner casing, the upper end of the screw 3 is fixedly connected to the top conductive strip 2, and the lower end is exposed on the lower side of the inner casing;

[0058] The nut 12 is fixedly installed in the middle of the installation housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com