Low-NOx sintering system based on double-layer ignition of double-layer cloth

A cloth and double-layer technology, applied in the field of low NOx sintering system, can solve the problems of long flue gas treatment process route, difficult disposal, and increased denitrification cost, so as to meet the requirements of ensuring sintering efficiency and catalyst, and is conducive to environmental protection. The effect of saving denitrification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

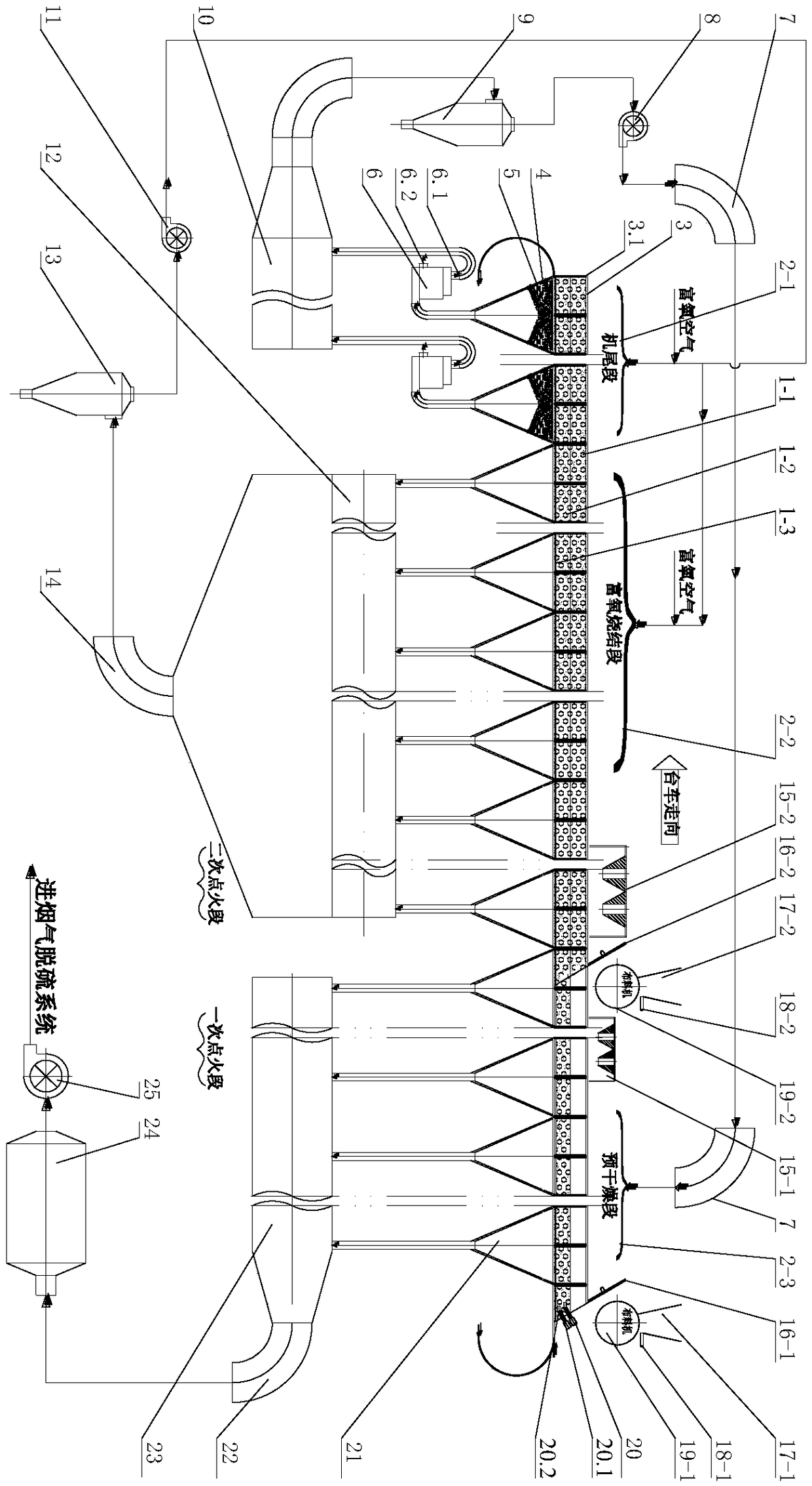

[0034] Example 1, see figure 1 , a low-NO x The sintering system includes a sintering machine 3, the sintering base material 1-3 is arranged on the sintering machine 3, and the bellows 21 is arranged under the trolley 3.1 of the sintering machine 3. Along the traveling direction of the trolley, the sintering machine 3 is sequentially divided into a lower sintering mixture distribution section, a pre-drying section, a primary ignition section, an upper sintering mixture distribution section, a secondary ignition section, an oxygen-enriched sintering section, and a tail section. Above the lower floor sintering mixture distribution section, be provided with the lower floor sintering mixture distribution machine 19-1 for laying the lower floor sintering mixture 1-2 on the sintering machine 3, and the lower floor sintering mixture distribution machine 19-1 is connected with the lower floor sintering mixture respectively. The lower hopper 17-1, the lower layer sintering mixture fee...

Embodiment 2

[0046] Embodiment 2, a kind of low NO based on double-layer cloth double-layer ignition x The sintering system includes a sintering machine, which is equipped with a sintering bottom material, and a bellows is installed under the trolley of the sintering machine, and the bellows discharges the flue gas; along the traveling direction of the trolley, the sintering machine is divided into the lower sintering mixture distribution section, the primary Ignition section, upper layer sintering mixture distribution section, secondary ignition section, oxygen-enriched sintering section, machine tail section; above the lower layer sintering mixture distribution section, there is a lower layer sintering mixture distribution machine for laying the lower layer sintering mixture on the sintering machine , the lower layer sintered mixture distribution machine is respectively connected with the lower layer sintered mixture discharge hopper, the lower layer sintered mixture discharge gate, and t...

Embodiment 3

[0047] Example 3 is different from Example 2 in that several sintering mixture distribution sections and ignition sections are provided between the secondary ignition section and the oxygen-enriched sintering section, and one sintering mixture distribution section corresponds to one ignition section.

[0048] The invention has the advantages of simple system, energy saving and environmental protection, saving investment cost of pollutant treatment, and can effectively reduce NO in the sintering process. x , Dioxin and dust emission concentration characteristics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com