A constant pressure control system and method for chemical grouting pump

A chemical grouting, constant pressure control technology, applied in pump control, pump testing, liquid variable capacity machinery, etc., can solve the problems of unsafe operation, poor dynamic performance of chemical grouting pump pressure regulation, low stability, etc. Accurate pressure control, guaranteed pressure stability, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

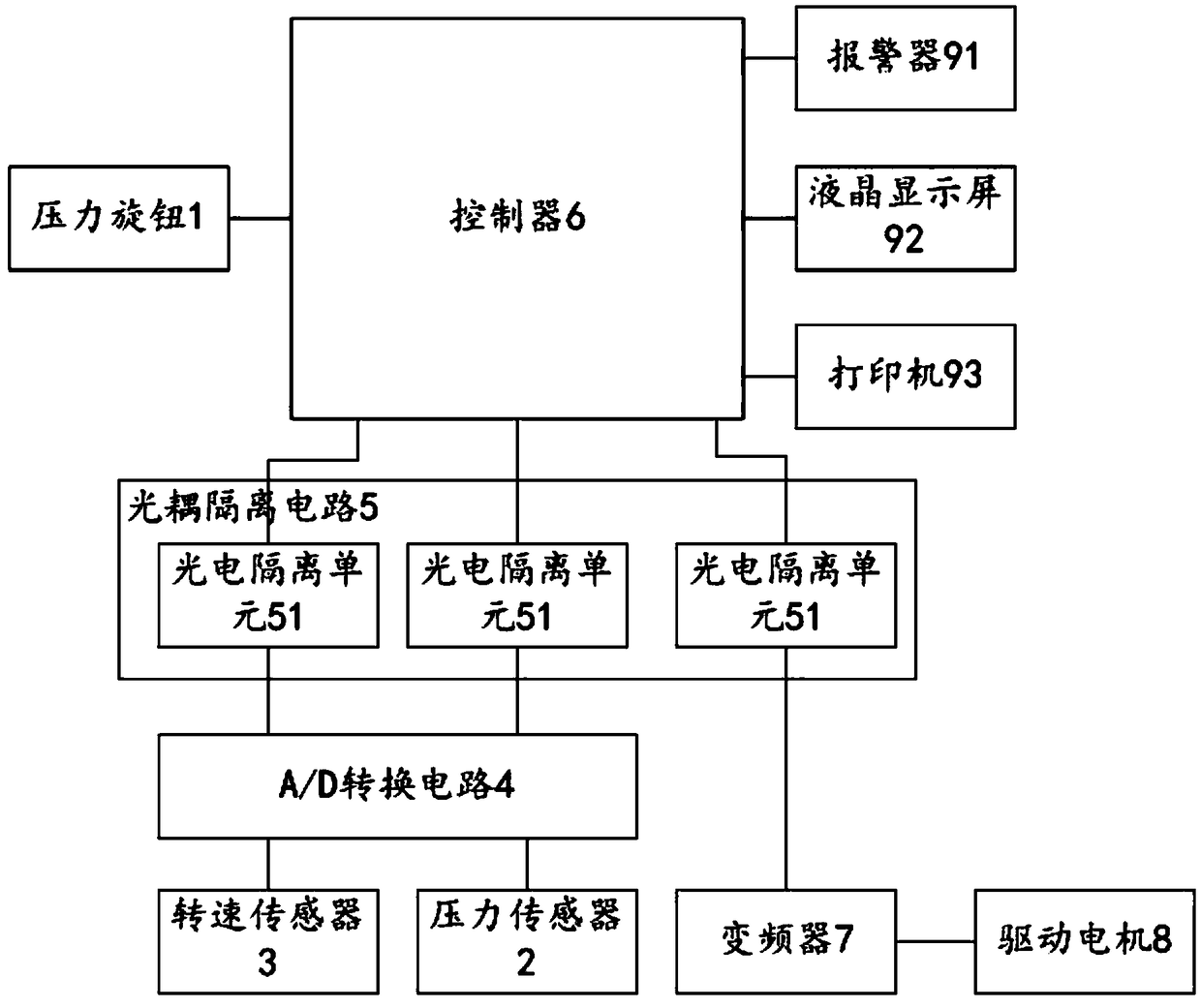

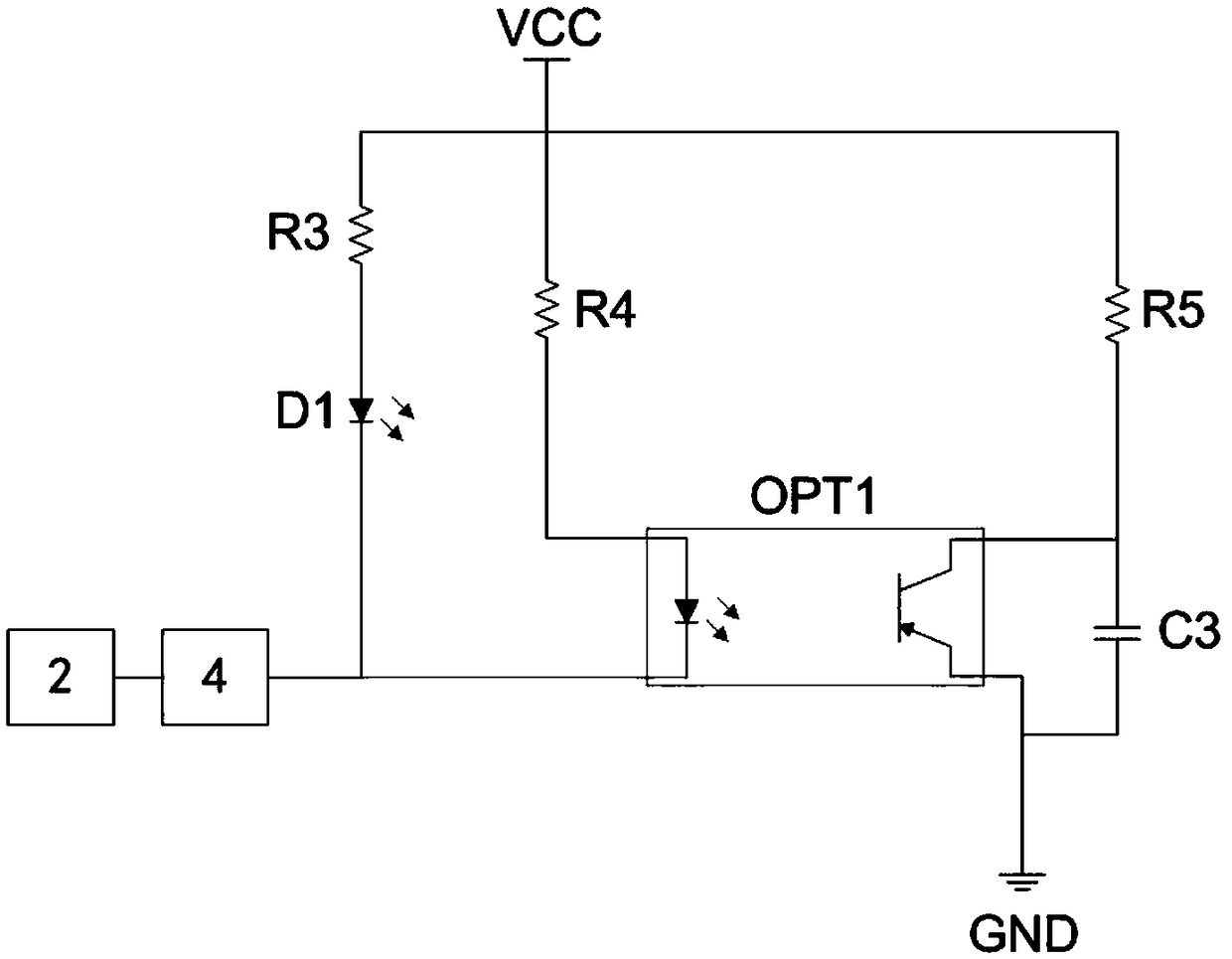

[0026] Such as figure 1 As shown, Embodiment 1 of the present invention provides a chemical grouting pump constant pressure control system, hereinafter referred to as the constant pressure control system, including a pressure knob 1, a pressure sensor 2, a speed sensor 3, an A / D conversion circuit 4, an optocoupler An isolation circuit 5, a controller 6, a frequency converter 7, and a drive motor 8, the pressure knob 1 is electrically connected to the controller 6, and the pressure sensor 2 and the rotational speed sensor 3 are connected to each other through the A / D conversion circuit 4 and The optocoupler isolation circuit 5 is electrically connected, the optocoupler isolation circuit 5 is electrically connected to the controller 6, and the controller 6 is also electrically connected to the frequency converter 7 through the optocoupler isolation circuit 5, so The driving motor 8 is electrically connected to an external power supply through the frequency converter 7, the pres...

Embodiment 2

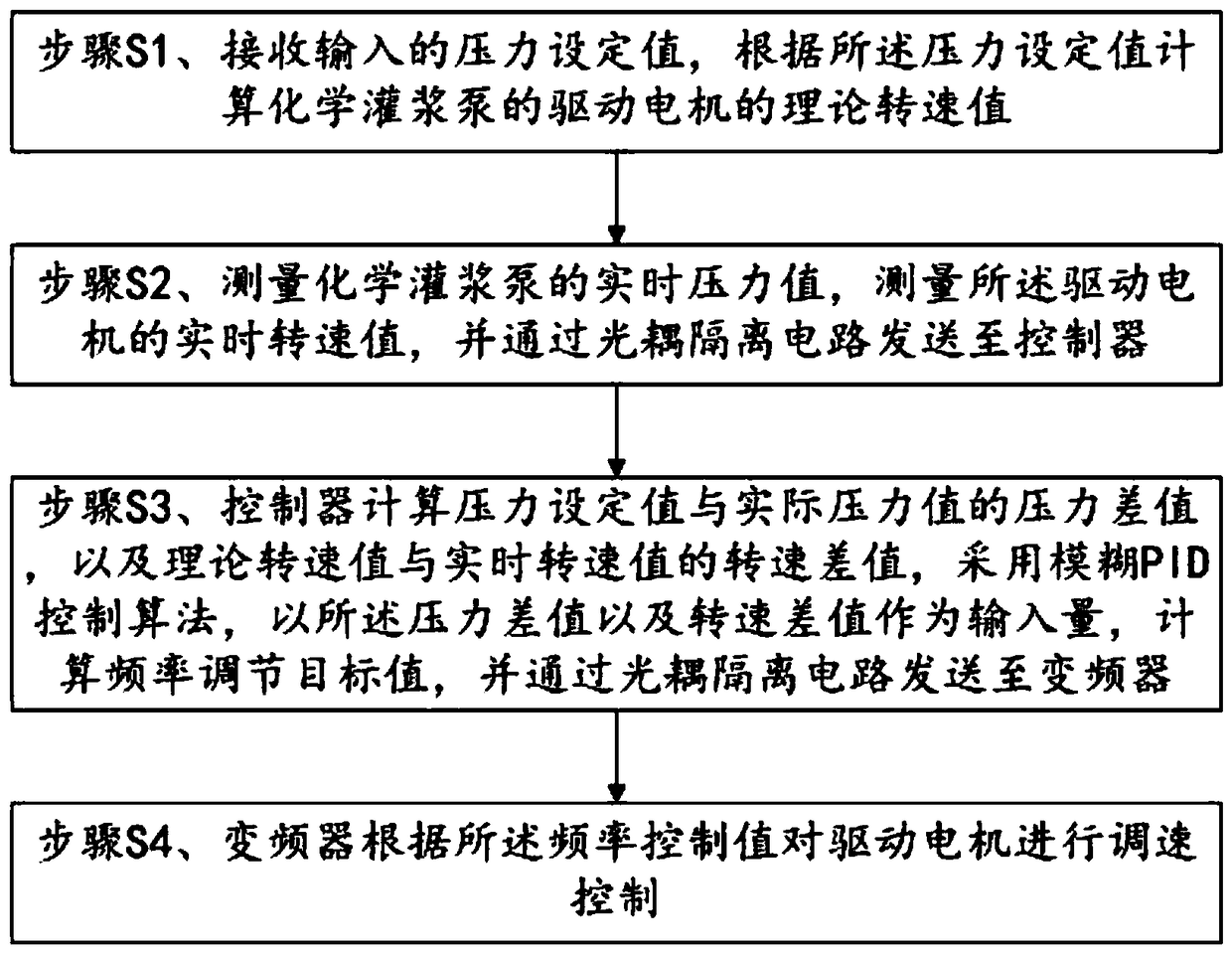

[0054] Such as image 3 As shown, Embodiment 2 of the present invention provides a method for controlling constant pressure of a chemical grouting pump, comprising the following steps:

[0055] Step S1, receiving the input pressure setting value, and calculating the theoretical rotational speed value of the driving motor of the chemical grouting pump according to the pressure setting value;

[0056] Step S2, measure the real-time pressure value of the chemical grouting pump, measure the real-time speed value of the driving motor, and send it to the controller through the optocoupler isolation circuit;

[0057] Step S3, the controller calculates the pressure difference between the pressure setting value and the actual pressure value, and the speed difference between the theoretical speed value and the real-time speed value, and adopts the fuzzy PID control algorithm, using the pressure difference and the speed difference as input Calculate the frequency adjustment target value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com