Processing technology of acid and alkali resistant fabric

A processing technology, acid and alkali resistance technology, applied in the processing of textile materials, processing textile material carriers, conjugated rayon, etc., can solve the problems of unusable, single fabric structure, etc., to improve the flatness and drying effect. Good, the effect of preventing movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

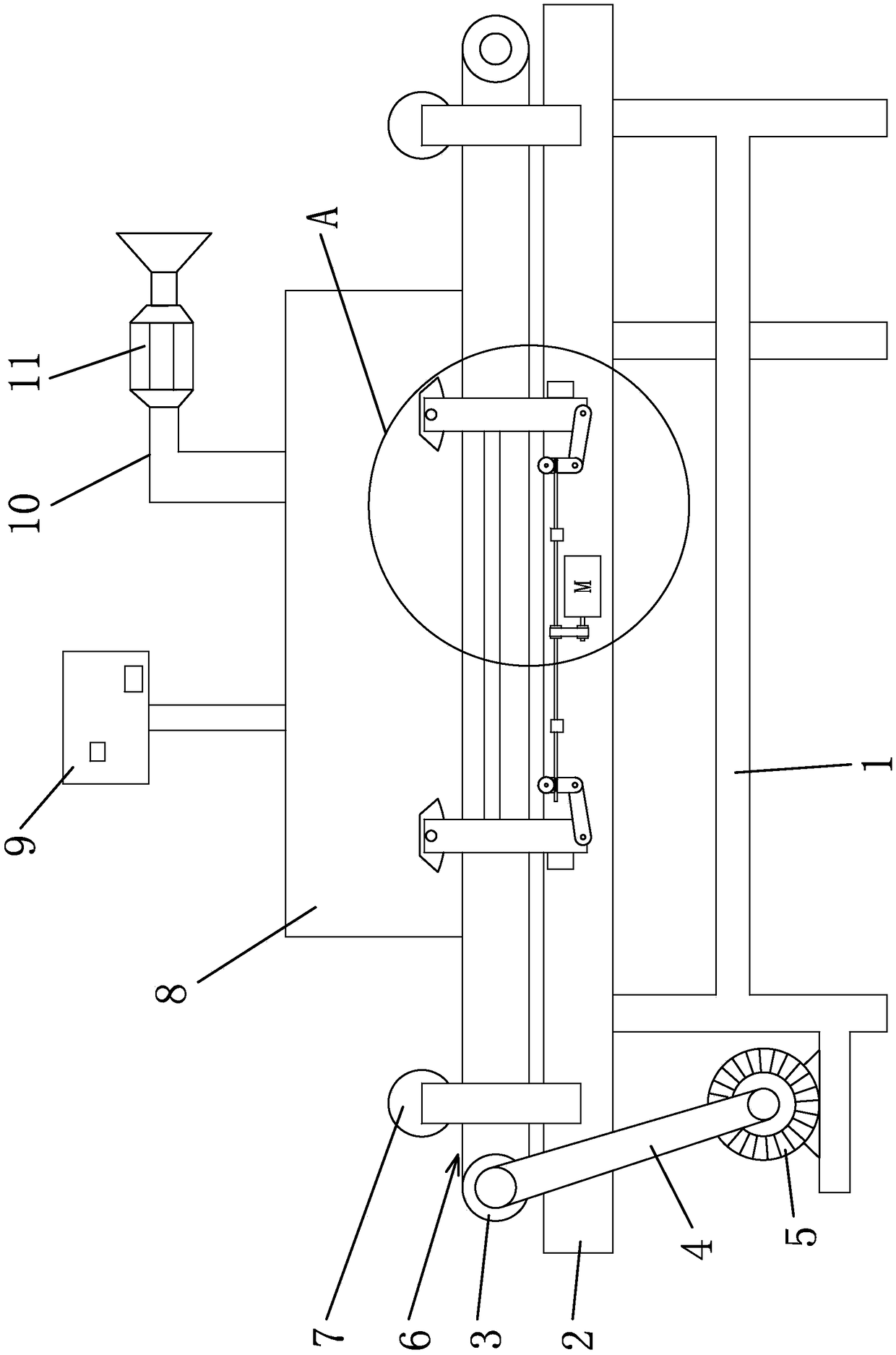

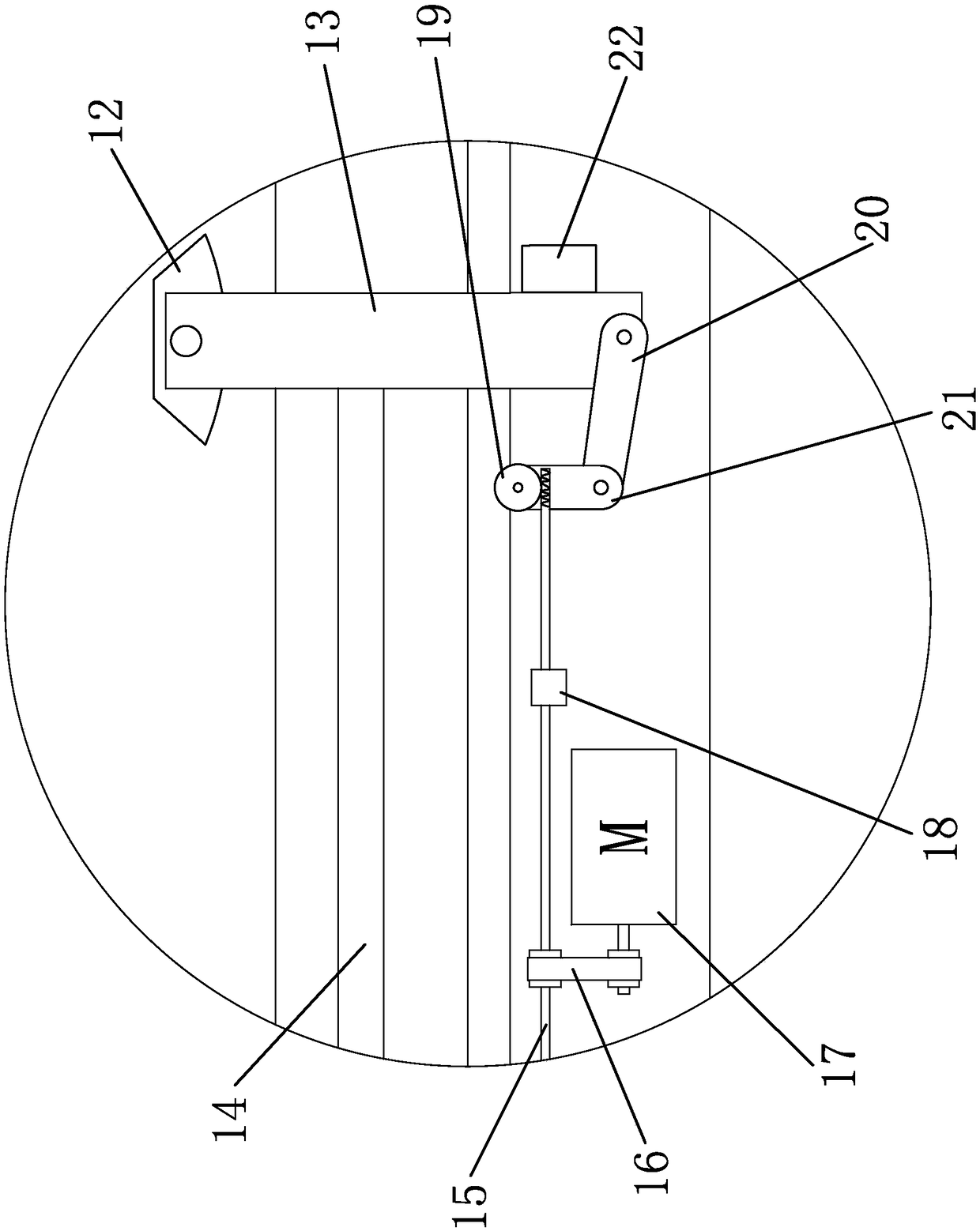

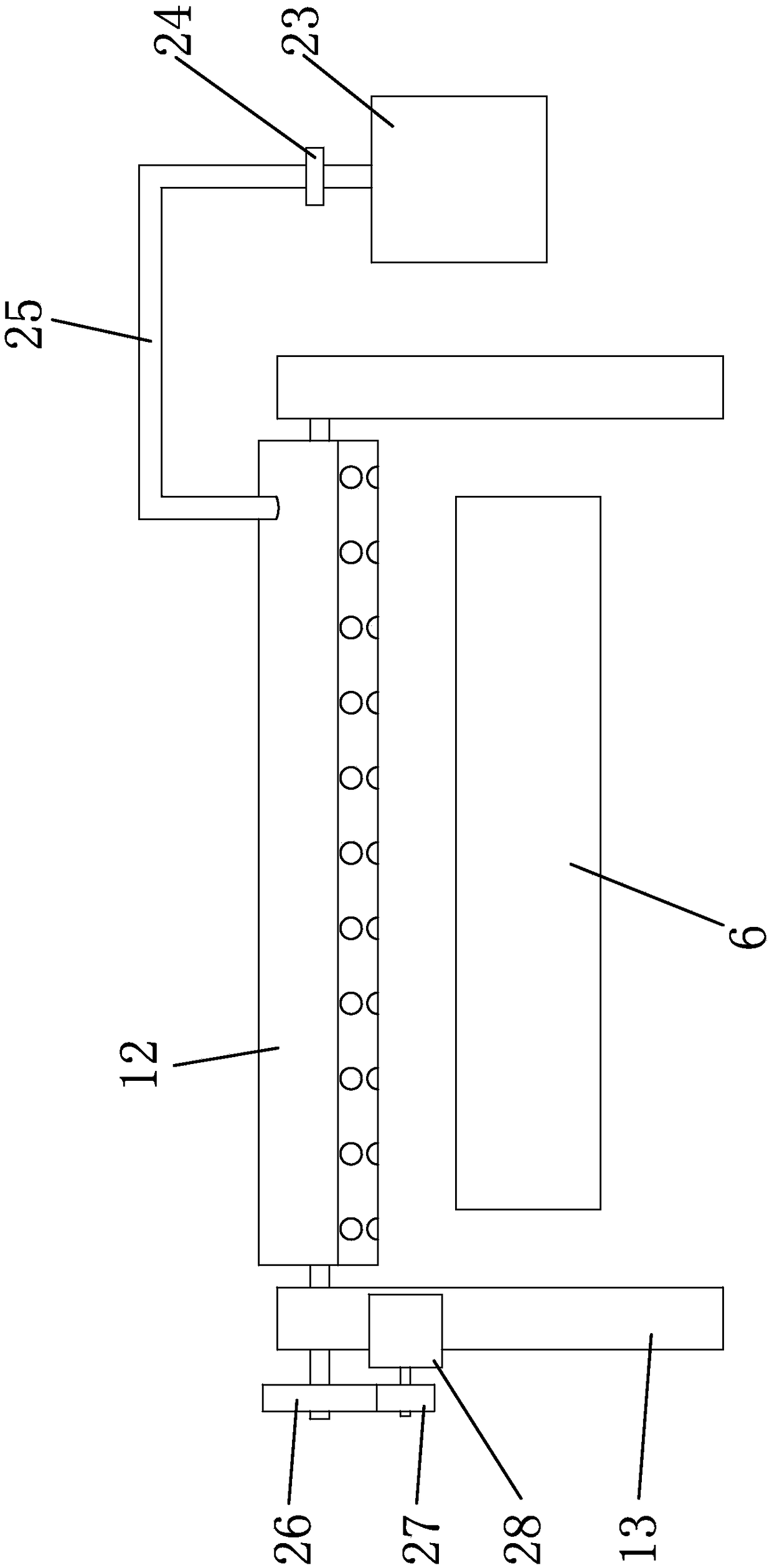

[0038] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

[0039] The processing technology of the acid and alkali corrosion resistant fabric comprises the following steps:

[0040]a. Ultrasonic pulverization: by weight, take 9-12 parts of bamboo fiber, 25-30 parts of soybean fiber, 15-20 parts of spandex fiber and 2-4 parts of citric acid and soak them in 5% hydrogen peroxide Sterilize and activate, dry after soaking for 3-4h, then put into an ultrasonic pulverizer with a power of 160-240kW and pulverize for 25-35min to obtain pulverized objects; in the present embodiment, 11 parts of bamboo fibers are taken in parts by weight , 26 parts of soybean fiber, 17 parts of spandex fiber and 3 parts of citric acid are soaked in 5% hydrogen peroxide for disinfection and activation, soaked for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com