Continuous device for preparing benzaldehyde midbody and application thereof

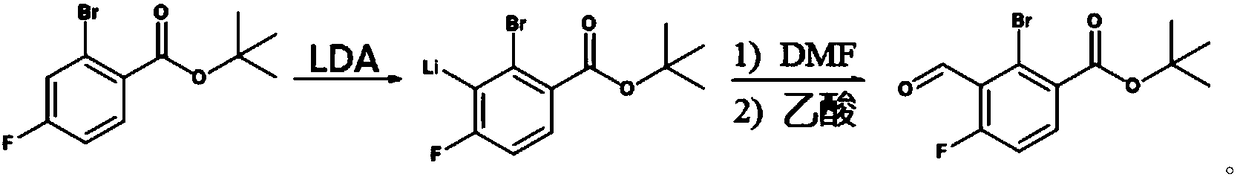

A chemical device and technology of benzaldehyde, applied in the field of continuous devices for preparing benzaldehyde intermediates, can solve the problems of poor reaction selectivity and harsh reaction conditions, and achieve the goal of improving reaction selectivity, short reaction time and fast reaction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

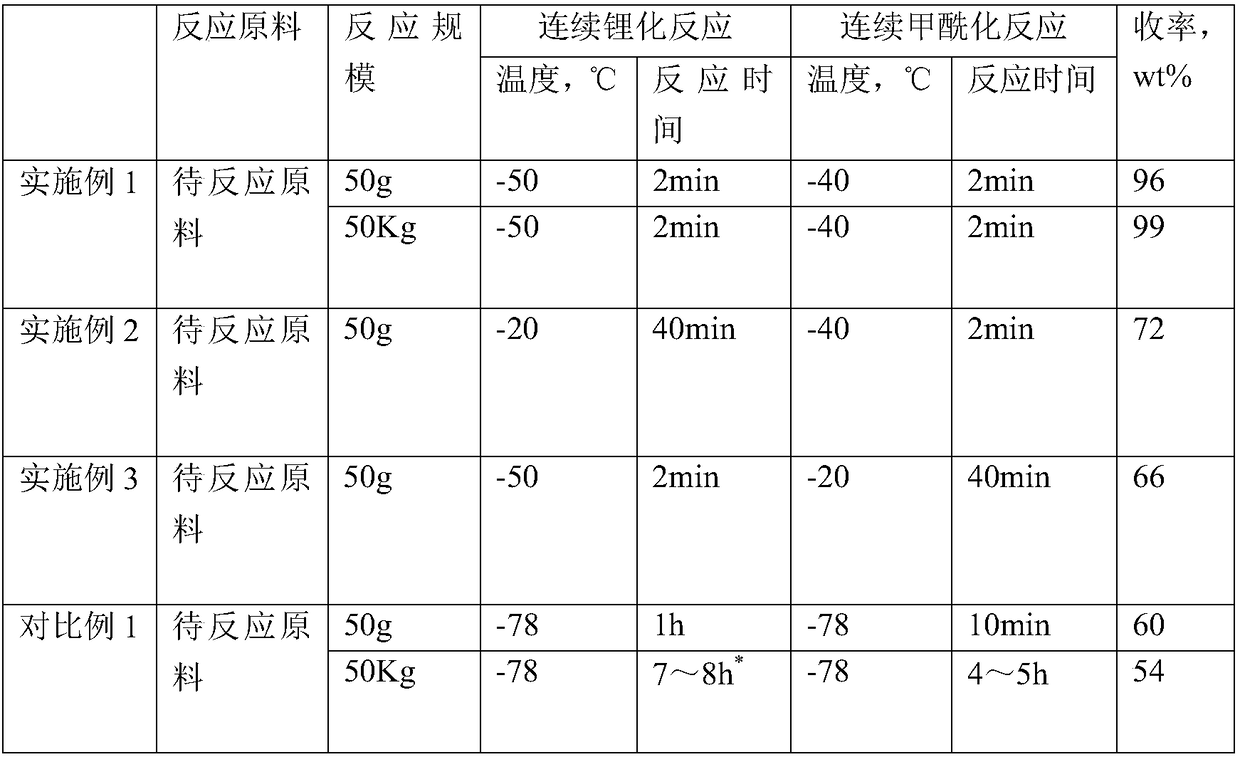

Embodiment 1

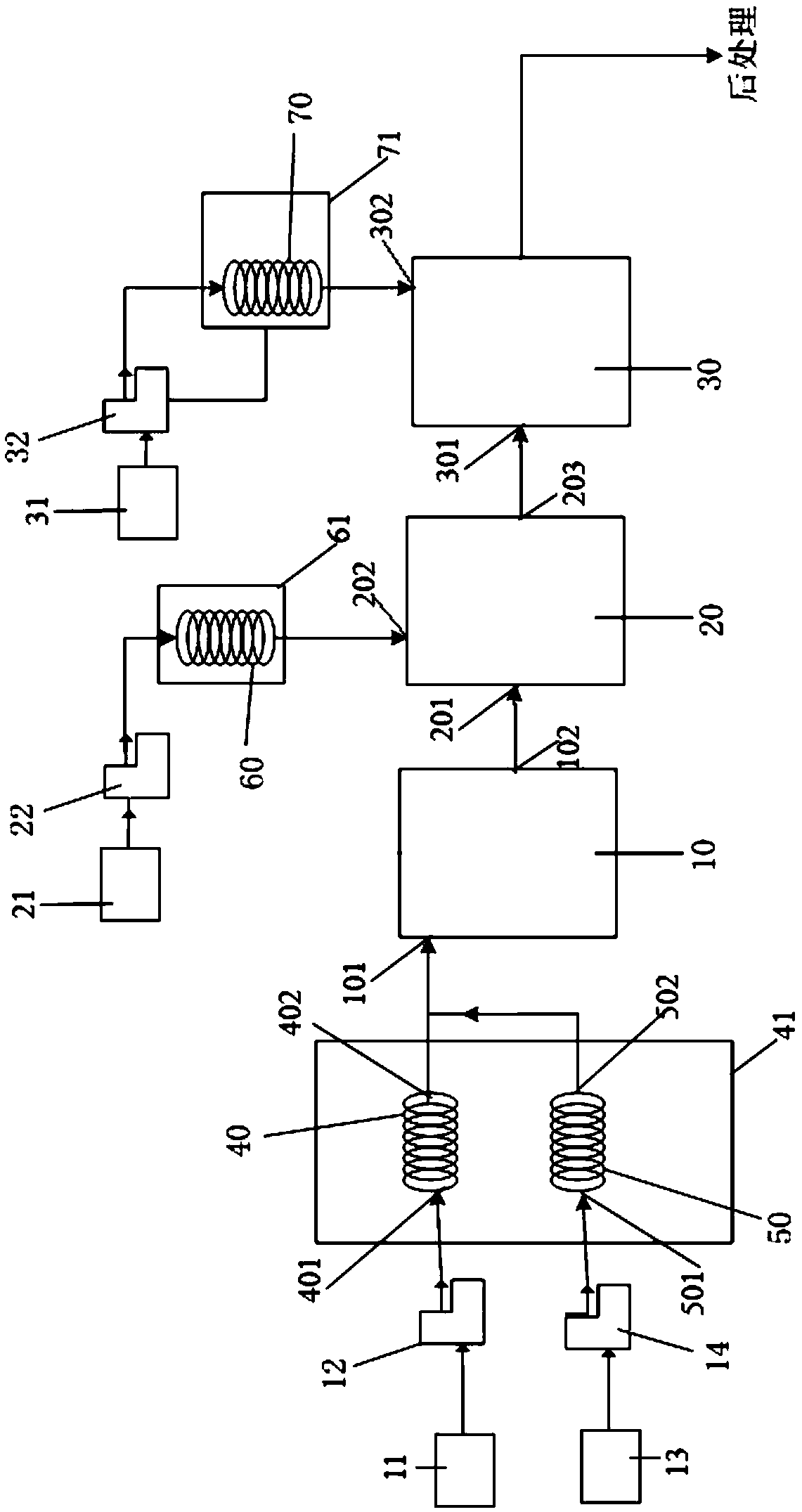

[0054] use as figure 1 The shown device prepares benzaldehyde intermediates, and the specific operation process is as follows:

[0055]The prepared 2-bromo-4-fluorobenzaldehyde tert-butyl tetrahydrofuran solution (1.0 equivalent) is output from the raw material liquid supply device 11, and is transported to the first precooling device 40 continuous coil reactor through the second delivery pump 12 , Lithium diisopropylamide (1.1 equivalents) is transported to the second pre-cooling unit 50 by the organolithium reagent supply unit 13 by the third delivery pump 14, and is carried out under the effect of the first jacket outer bath temperature control unit 41 temperature control. The pre-cooled raw material solution and the organic lithium reagent solution are mixed in the continuous lithiation reaction device 10 and undergo a first-stage continuous lithiation reaction to obtain a lithiation product. During the reaction, the raw material solution and the organic lithium reagent ...

Embodiment 2

[0060] The difference from Example 1 is that the reaction temperature of the continuous lithiation reaction is -20° C. and the reaction time is 40 minutes.

Embodiment 3

[0062] The difference from Example 1 is: the reaction temperature of the continuous formylation reaction is -20° C. and the reaction time is 40 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com