Method for constructing metal-based surface with alternate hydrophilic and hydrophobic strips

A metal and hydrophobic technology, which is applied to special surfaces, pre-treated surfaces, and devices for coating liquids on surfaces, can solve the problems of limited construction methods and expensive processing costs of hydrophilic-hydrophobic stripes and alternate surfaces, and achieves low-cost structural parameters. Effects with controllable parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

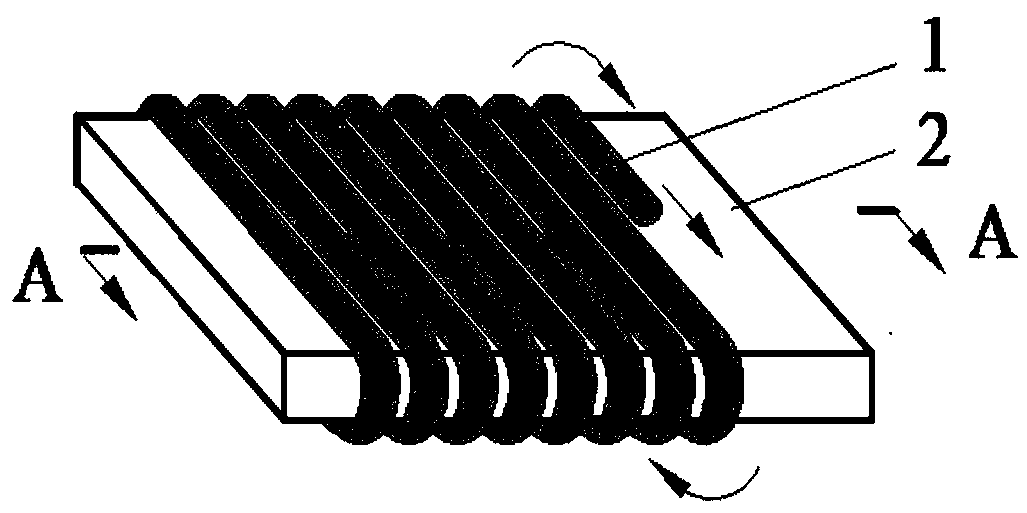

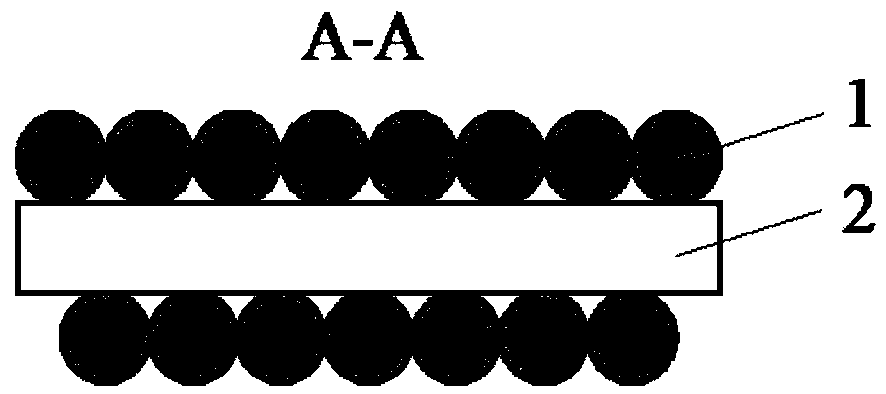

[0037] The substrate is made of aluminum-magnesium alloy, and the metal wire is made of pure aluminum. The surface of the 50mm*50mm square and 10mm thick aluminum-magnesium alloy is ground and polished, and then the oil and oxides are removed together with the pure aluminum wire with a diameter of 100μm: use acetone and alcohol in sequence , rinsed with deionized water, and dried with nitrogen gas for later use.

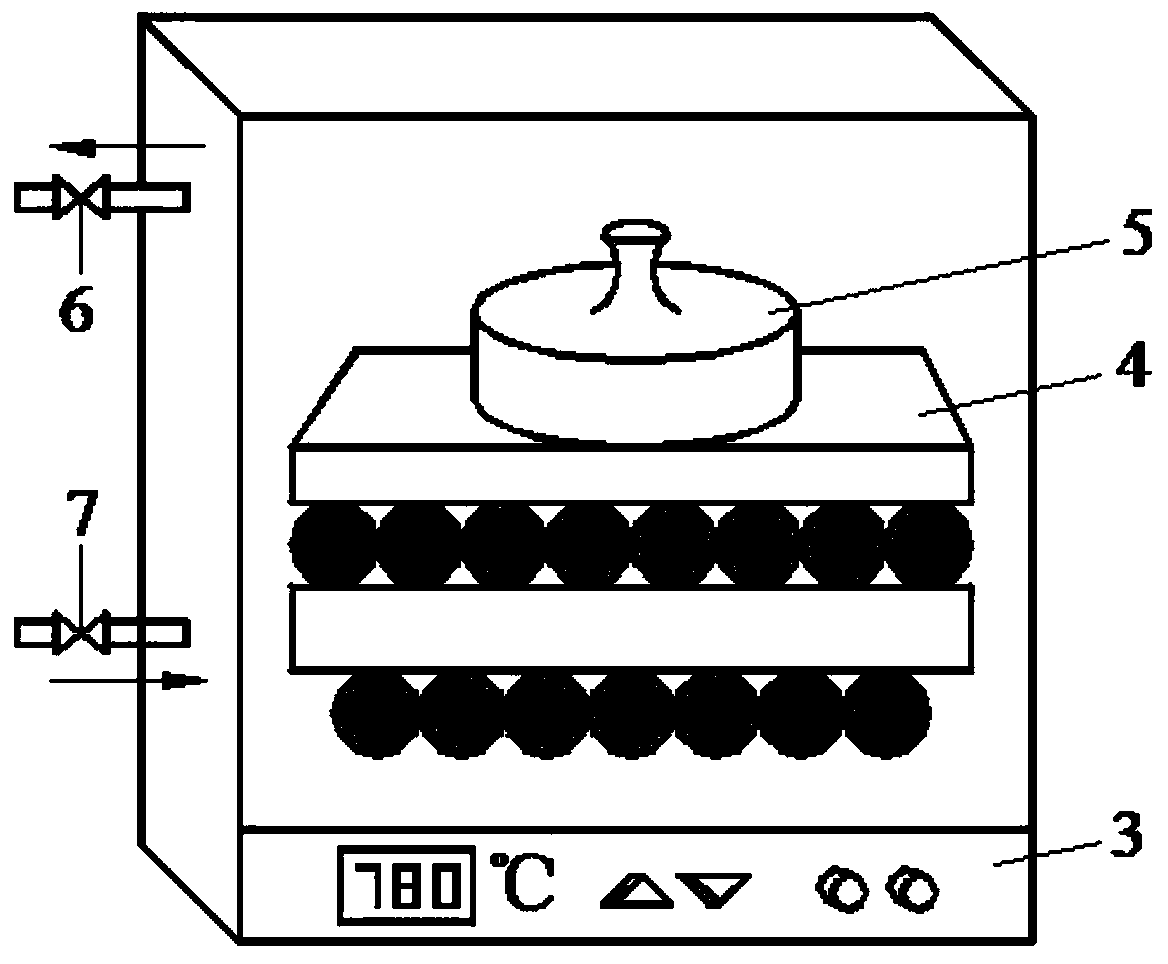

[0038] The clean aluminum wire is tightly wound on the polished and clean aluminum-magnesium alloy substrate, and put into the atmosphere sintering furnace. A 5kg stainless steel ingot weight is placed on the closely arranged aluminum wires to apply compressive stress, and the aluminum wire and the stainless steel ingot weight are separated by a graphite plate to prevent the two from sticking under high temperature sintering. After vacuuming the furnace, fill it with 40kPa nitrogen, raise the temperature to 550°C, keep it warm for 4 hours and cool it to room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com