Preparation method and application of functional single-walled carbon nanohorn

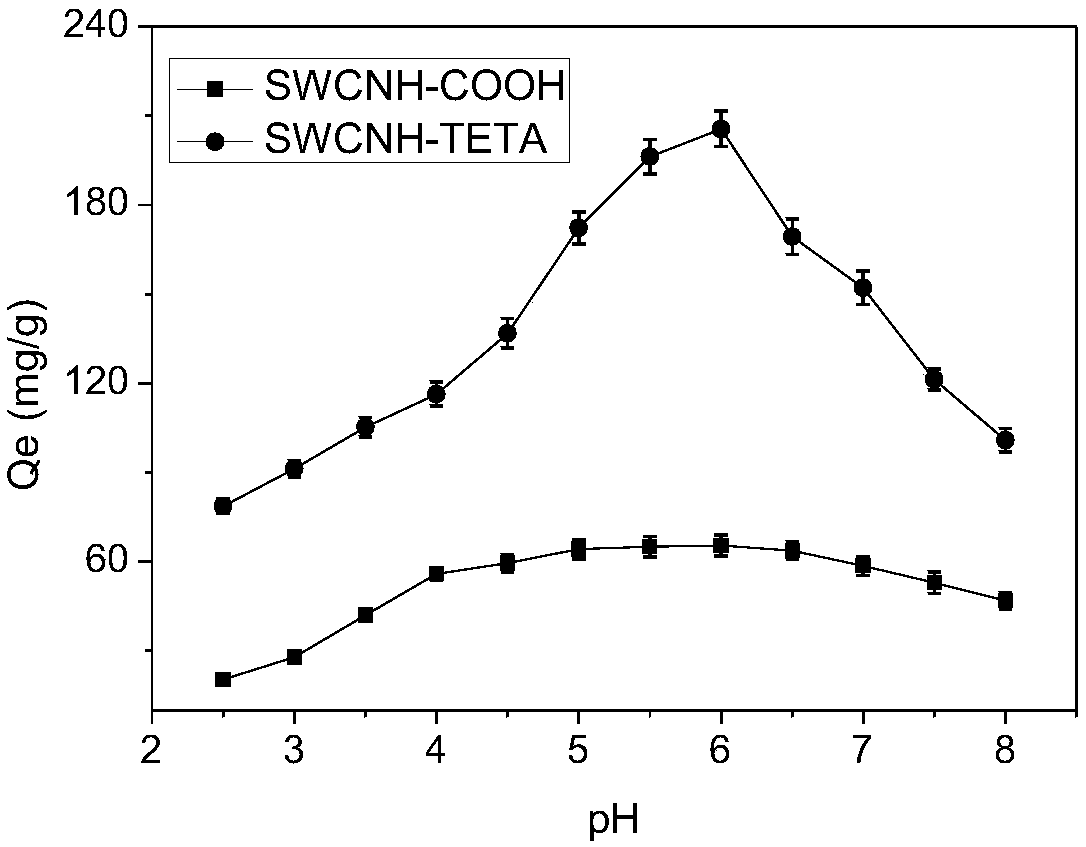

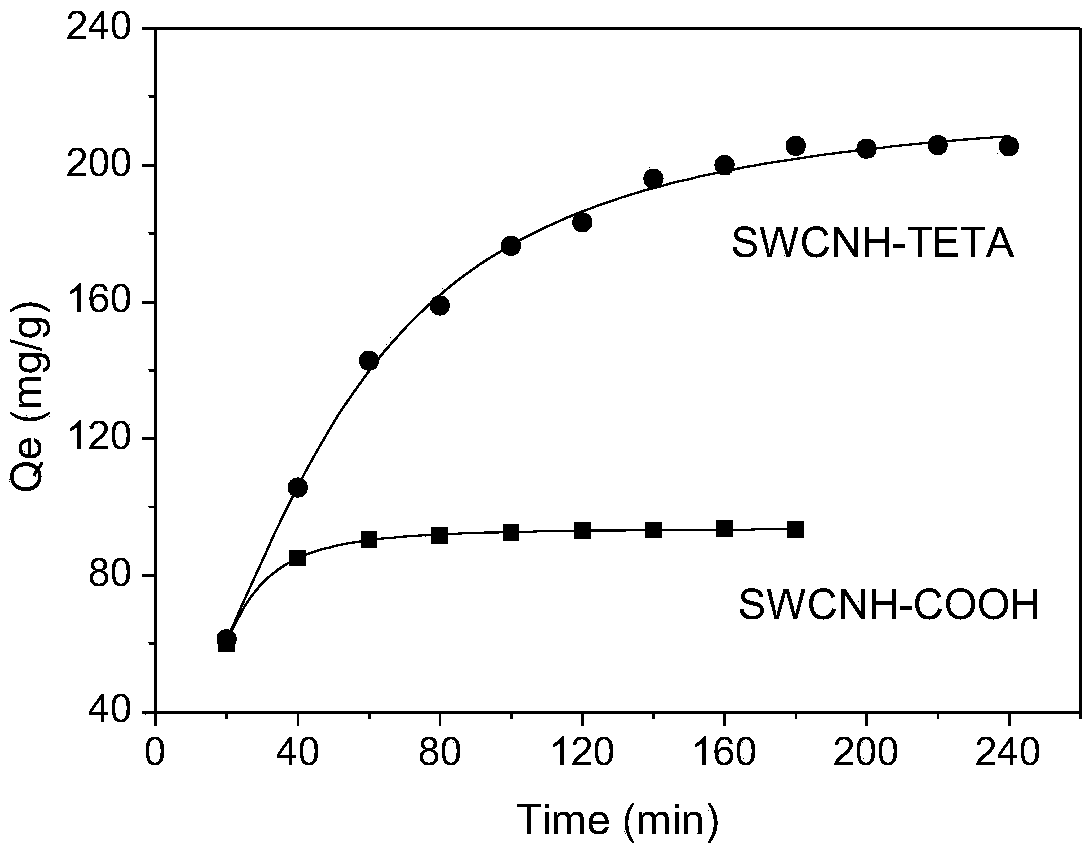

A single-wall carbon nanohorn, functionalized technology, applied in chemical instruments and methods, inorganic chemistry, radioactive purification, etc., can solve the problems of difficult separation of impurities, no good way to remove, small adsorption capacity, etc., and achieve high adsorption. The speed, the method is simple, the effect of high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing functionalized single-walled carbon nanohorns, comprising the following steps:

[0029] Step 1: Modification of SWCNH

[0030] Disperse 100 mg of SWCNH into 150 mL of nitric acid solution and reflux at 100 ° C for 24 hours to obtain a carboxylated SWCNH (SWCNH-COOH) dispersion, which is centrifuged, washed and filtered with deionized water several times until the filtrate becomes neutral, Then vacuum-dry, then disperse the carboxylated single-walled carbon nanohorn in deionized water, and prepare a 0.5 mg / mL dispersion for subsequent use;

[0031] Step 2: Triethylenetetramine functionalized SWCNH (SWCNH-TETA)

[0032]Using carboxylated single-walled carbon nanohorn (SWCNH-COOH) and triethylenetetramine (TETA) as reaction raw materials, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride ( EDC) / N-hydroxysuccinimide (NHS) as a catalyst, under the protection of nitrogen, the reaction temperature was controlled at 70 ° C, reacted for 12 hour...

Embodiment 2

[0034] A method for preparing functionalized single-walled carbon nanohorns, comprising the following steps:

[0035] Step 1: Modification of SWCNH

[0036] Disperse 150 mg of SWCNH into 200 mL of nitric acid solution and reflux at 120 ° C for 24 hours to obtain a carboxylated SWCNH (SWCNH-COOH) dispersion, which is centrifuged, washed and filtered with deionized water for several times until the filtrate becomes neutral, Then vacuum-dry, then disperse the carboxylated single-walled carbon nanohorn in deionized water, and prepare a 1.0 mg / mL dispersion for subsequent use;

[0037] Step 2: Triethylenetetramine functionalized SWCNH (SWCNH-TETA)

[0038] Using carboxylated single-walled carbon nanohorn (SWCNH-COOH) and triethylenetetramine (TETA) as reaction raw materials, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride ( EDC) / N-hydroxysuccinimide (NHS) as a catalyst, under the protection of nitrogen, the reaction temperature was controlled at 80 ° C, reacted for 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com