Exhaust gas denitration device and method of controlling exhaust gas denitration device

A waste gas and denitrification technology, which is applied in the direction of electric control of exhaust treatment devices, exhaust devices, chemical instruments and methods, etc., can solve problems such as high cost of combustion-supporting burners, changes in flow and temperature, and complicated device structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

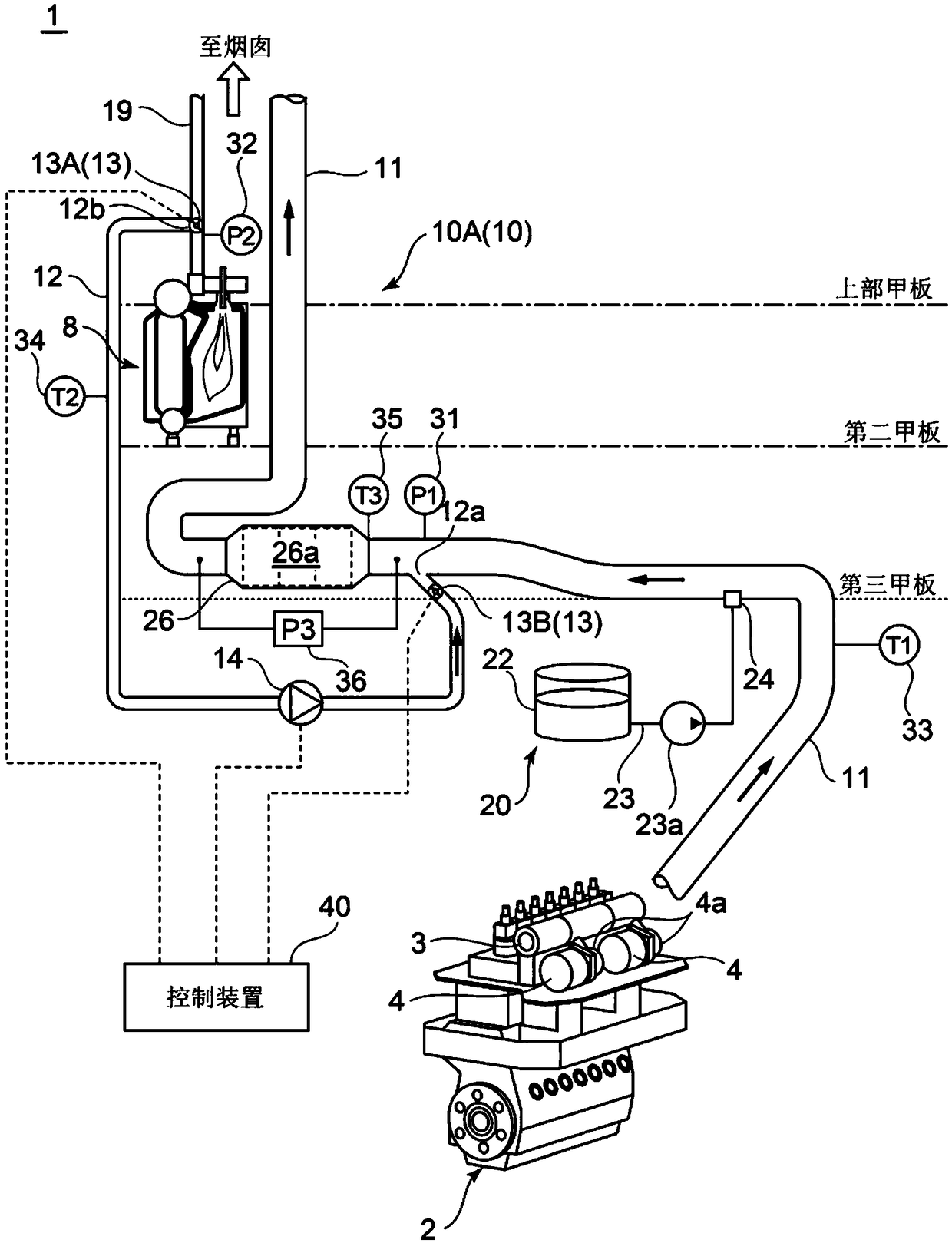

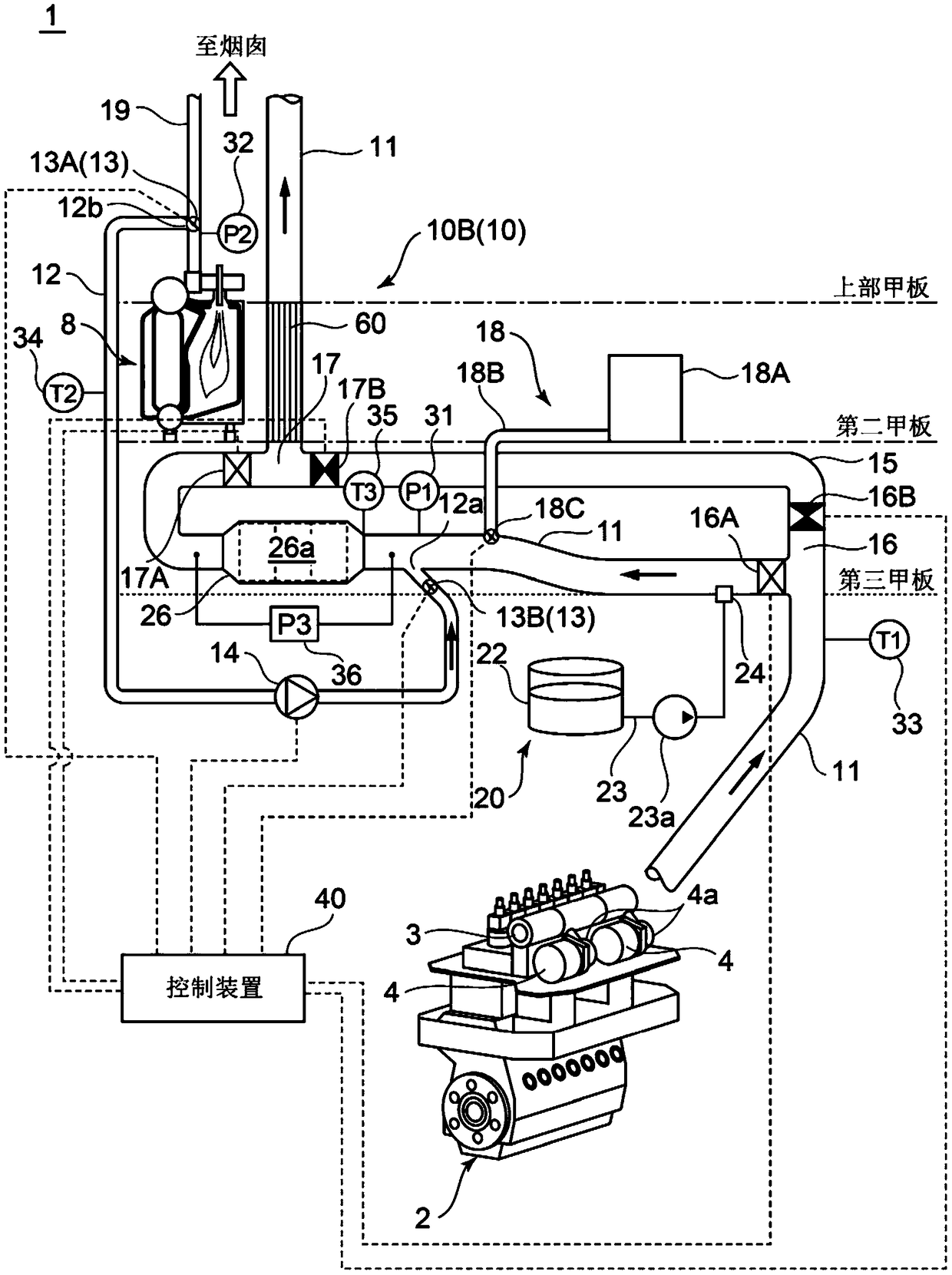

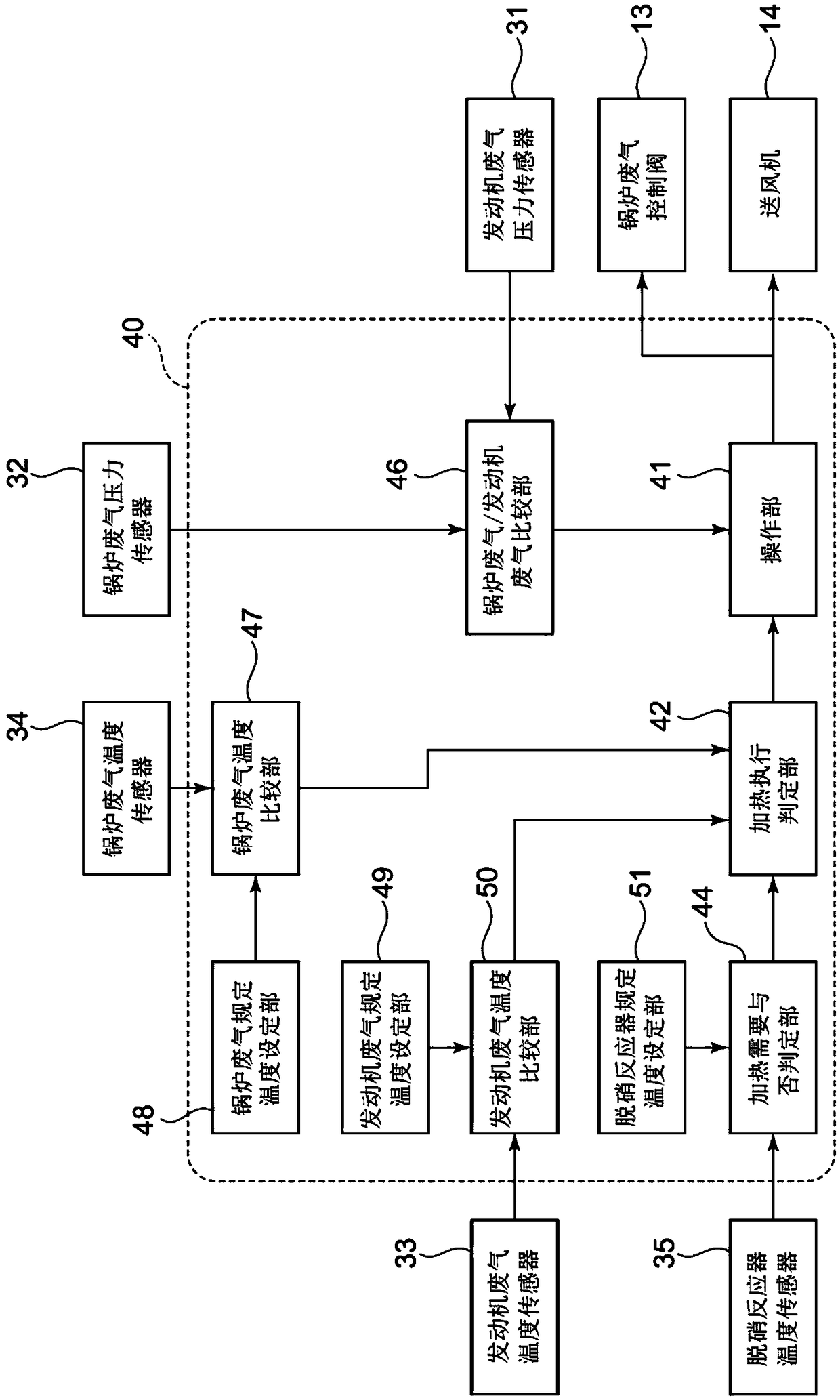

[0073] Hereinafter, several embodiments of the present invention will be described with reference to the drawings. However, dimensions, materials, shapes, relative arrangements, etc. of components described as embodiments or shown in the drawings are not intended to limit the scope of the present invention, but are merely illustrative examples.

[0074] For example, expressions such as "in a certain direction", "along a certain direction", "parallel", "orthogonal", "center", "concentric" or "coaxial" indicating relative or absolute configurations are not only strictly It shows such an arrangement, and also shows a state of being relatively displaced by an angle or a distance to the extent that a tolerance or the same function can be obtained.

[0075] For example, expressions such as "same", "equal" and "homogeneous" indicating that things are in an equal state not only strictly represent an equal state, but also express a state where there is a difference in the degree of tol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com