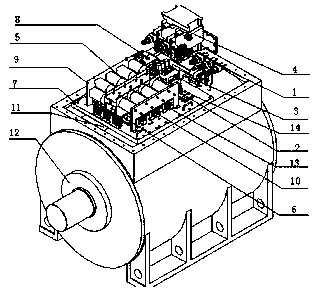

Main circuit structure of 1140V permanent magnet direct drive inverter-fed motor integrated machine

A variable frequency motor, permanent magnet direct drive technology, applied in the direction of connection with control/drive circuit, electrical components, AC power input conversion to AC power output, etc., can solve the problems of performance improvement, complex structure, large volume, etc., to achieve Simplify the structure of the main circuit, improve the input power factor, and the effect of small power supply impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

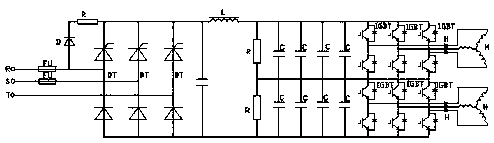

[0032] Embodiment 1 The main circuit structure of a 1140V permanent magnet direct drive variable frequency motor integrated machine, such as Figure 1-2 As shown, it includes a pre-charging unit (2), a rectifying unit (3), a filtering unit (5), an inverter unit (6), a cooling unit, and a motor unit (12). The units are connected through copper bars, laminated bus bars, etc.; the cooling unit is a water cooling plate (7).

[0033] After the power supply R, S, T is input, it is fixed on the input terminal (1), and connected to the pre-charging unit (2) and the rectifying unit (3) through copper bars. The three-phase input is respectively connected to the junction of the controllable thyristor module and the diode module of each bridge arm of the rectification unit.

[0034] The pre-charging unit (2) is composed of a common diode module and a resistor. Through copper bars and cables, one end is connected to the R-phase input, and the other end is connected to the rectified P-side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com