A Method for Reducing the Crimping Flash Rate of Conductor Tension Tubes of Overhead Transmission Lines

An overhead transmission line and tension-resistant technology, which is applied in the direction of connection and connection through deformation, can solve the problem of reducing the rate of crimping flashing of overhead transmission line conductors, the physical connection of flashes that are difficult to clean, and the crimping of straining tubes. Problems such as high edge rate, achieve the effect of reducing the probability of flashing, easy to clean, and reducing the probability of flashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

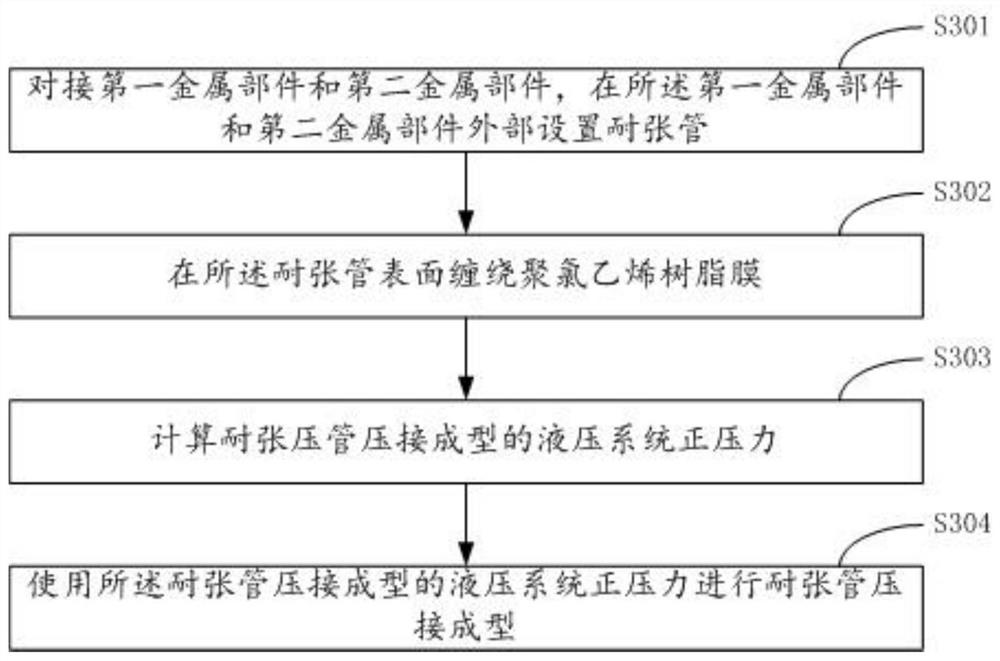

[0039] The core content of this patent is to wrap a polyvinyl chloride resin film on the surface of the strain-resistant tube to reduce the flash caused by excessive friction during the crimping process, and to use the calculated crimping force. The implementation mode will be further described.

[0040] The following will describe in detail an embodiment of a method for reducing the crimping burr rate of a tension tube of an overhead power transmission line conductor provided by the present invention.

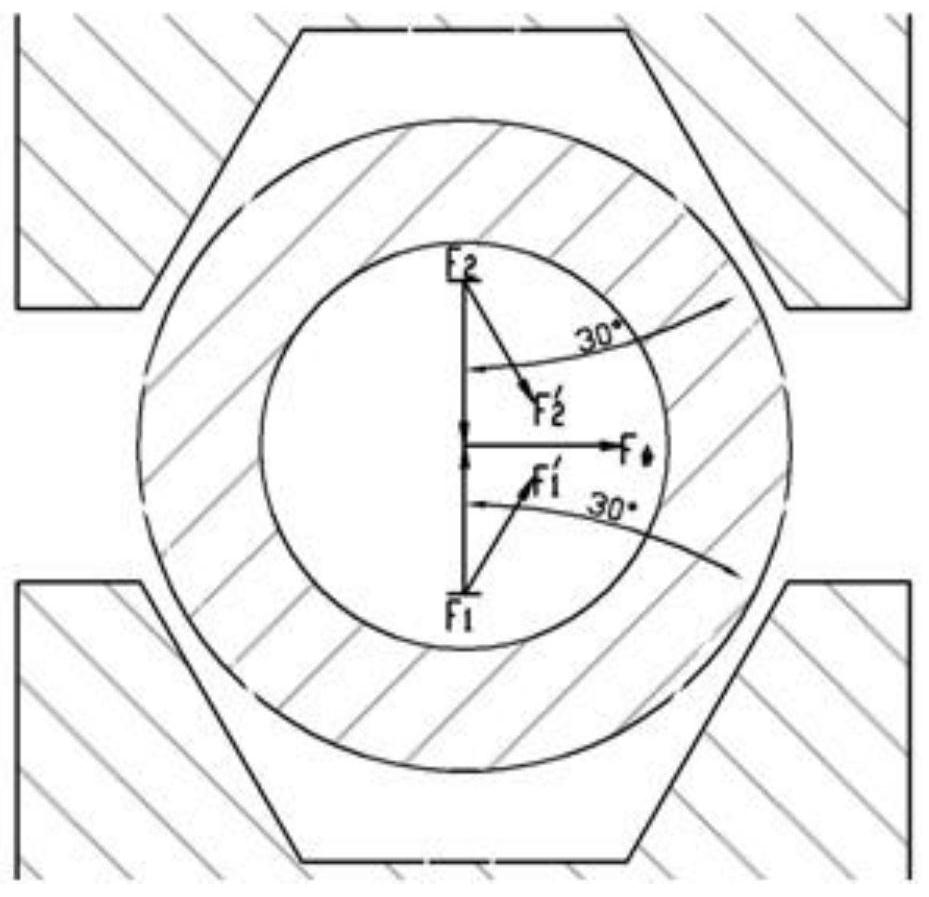

[0041] Such as figure 1 As shown, take KTACSR / EST-720 / 300 heat-resistant extra-strong steel-cored aluminum alloy stranded wire and supporting NY-720NH / 300EA strain clamp as an example for research and analysis.

[0042] The strain clamp consists of two parts: aluminum tube and steel tube. They are respectively crimped and connected with the lead aluminum alloy stranded wire and the steel core. The outer diameters of NY-720NH / 300EA tension clamp aluminum tube and steel tube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com