Method for directly preparing ternary positive electrode material modified by lithium zinc oxide by utilizing positive electrode material of waste lithium battery

A technology for waste lithium batteries and cathode materials, which is applied in the field of preparation of ternary material precursors, can solve problems such as poor stability of ternary cathode materials, and achieve the effects of improving electrochemical performance, good economy, and realizing directional circulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

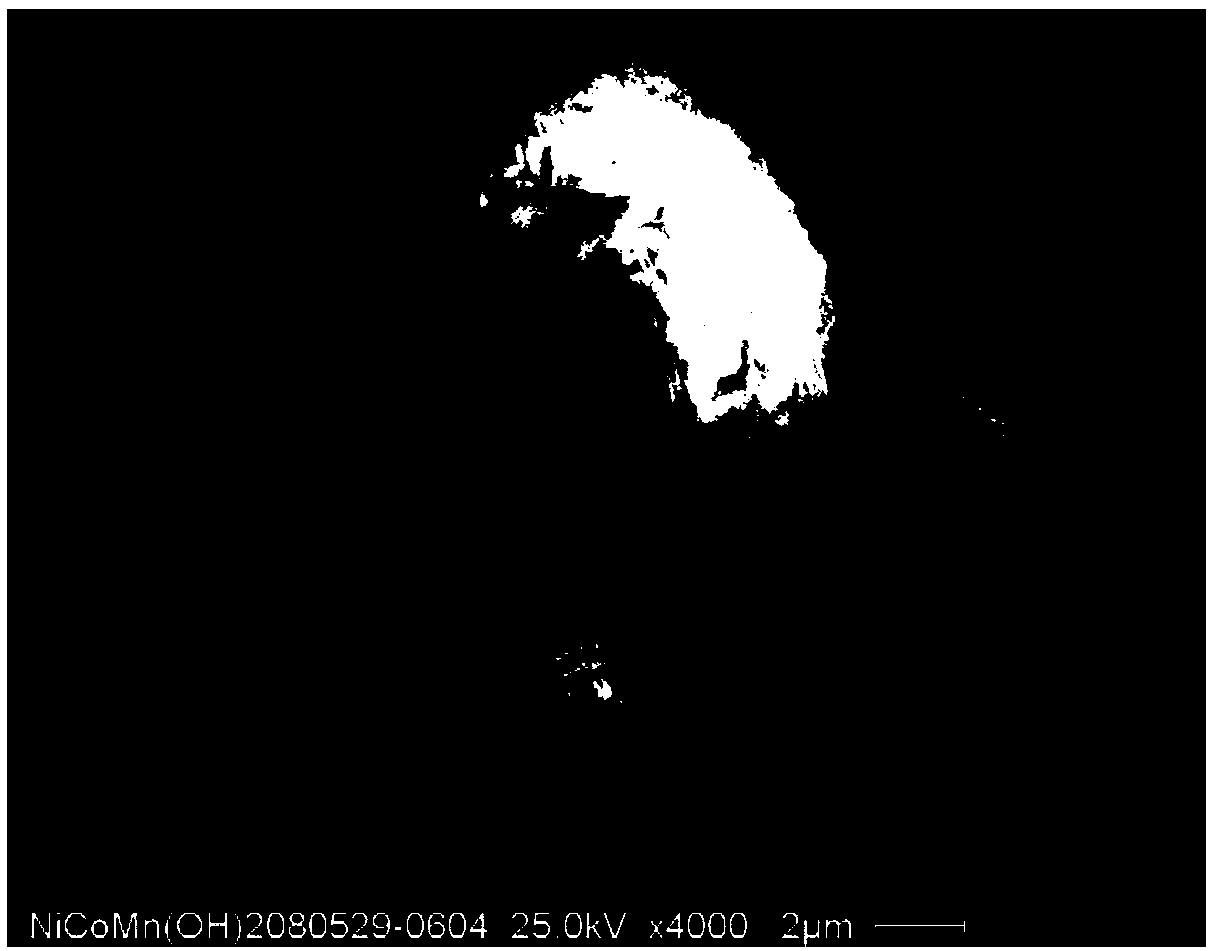

[0048] Disassemble and separate the positive electrode sheet from the waste lithium-ion battery and bake it at 650°C for 15 minutes. The obtained roasted product is crushed on a crusher, sieved, and the positive electrode material is separated from the aluminum foil; the molar ratio of nickel, cobalt, and manganese in the positive electrode material 5:2:3 and 8:1:1;

[0049] The positive electrode material was leached with 2.5 mol / L sodium hydroxide solution at 95°C for 40 minutes, the liquid-solid ratio of the sodium hydroxide solution to the positive electrode material was 10:1 during leaching, and the filtrate and filter cake were obtained by filtration;

[0050] Add sodium carbonate whose molar number is 0.5 times of the lithium ion molar number in the filtrate, stir and react at 25°C for 60min, generate a turbid liquid, filter to obtain lithium carbonate solid and filtrate, and the filtrate is 2.2mol / L sodium hydroxide solution; The recovery rate was 94.6%;

[0051] The ...

Embodiment 2

[0057] Disassemble and separate the positive electrode sheet from the waste lithium-ion battery and bake it at 580°C for 30 minutes. The obtained roasted product is crushed on a crusher, sieved, and the positive electrode material is separated from the aluminum foil; the molar ratio of nickel, cobalt, and manganese in the positive electrode material 3:3:3 and 4:2:2;

[0058] The positive electrode material was leached with 2.0 mol / L potassium hydroxide solution at 75°C for 60 minutes, the liquid-solid ratio of the potassium hydroxide solution to the positive electrode material was 8:1 during leaching, and the filtrate and filter cake were obtained by filtration;

[0059] Add potassium carbonate whose molar number is 0.5 times the lithium ion molar number in the filtrate, stir and react at 40°C for 50min, generate a turbid liquid, filter to obtain lithium carbonate solid and filtrate, and the filtrate is potassium hydroxide solution of 1.5mol / L; The recovery rate was 94.2%;

...

Embodiment 3

[0066] Disassemble and separate the positive electrode sheet from the waste lithium-ion battery and bake it at 500°C for 45 minutes. The obtained roasted product is crushed on a crusher, sieved, and the positive electrode material is separated from the aluminum foil; the molar ratio of nickel, cobalt, and manganese in the positive electrode material 8:1:1 and 4:2:2;

[0067] The positive electrode material was leached with 1.5mol / L potassium hydroxide solution at 50°C for 100 minutes, the liquid-solid ratio of the potassium hydroxide solution to the positive electrode material was 6:1 during leaching, and the filtrate and filter cake were obtained by filtration;

[0068] Add potassium carbonate whose molar number is 0.5 times the lithium ion molar number in the filtrate, stir and react at 65°C for 30min, generate a turbid liquid, filter to obtain lithium carbonate solid and filtrate, and the filtrate is potassium hydroxide solution of 1.0mol / L; The recovery rate is 94.5%;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com