Machine vision-based online detection method for apertures of LED glass lamp cups

A technology of LED glass and machine vision, applied in instruments, measuring devices, image data processing, etc., can solve problems such as inability to guarantee product quality consistency, low manual inspection efficiency, and inability to conduct online inspections, so as to improve the comprehensive competitiveness of enterprises. , save labor costs, improve the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The LED glass lamp cup moves along the moving direction of the conveyor belt. When it moves to the detection area, the photoelectric sensor obtains the arrival signal of the LED glass lamp cup. After conditioning, the signal triggers the camera to take a frame of photos, and the collected images are transmitted to the industrial PC through the cable. Computer and PC carry out the corresponding image processing program, and the result of image processing is transmitted to the control module through RS232 in the form of instructions. If it is a lamp cup with an unqualified aperture, the STM32 control system controls the air claw and the cylinder to separate it by driving the solenoid valve and the air pump. Otherwise, the STM32 control system does not perform any operation, and the lamp cup with a qualified aperture flows to the next process. The specific steps of the image processing program are as follows:

[0044] Step (1): Threshold segmentation:

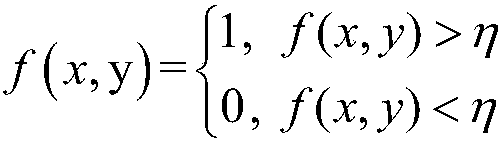

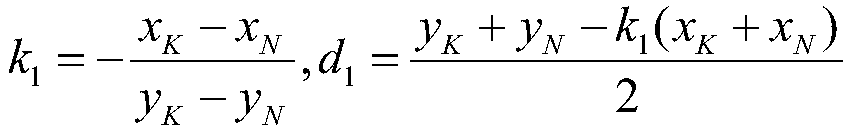

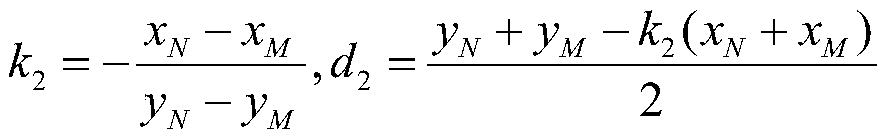

[0045] f(x, y) re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com