Shear force evaluation method for asymmetrical steel beam square steel pipe column nodes

An evaluation method and technology for square steel pipes, applied in the directions of instrumentation, design optimization/simulation, calculation, etc., can solve the problems of reduced universality and reliability, low eigenvalues of load calculation structures, and unsuitable high and low beam-column joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

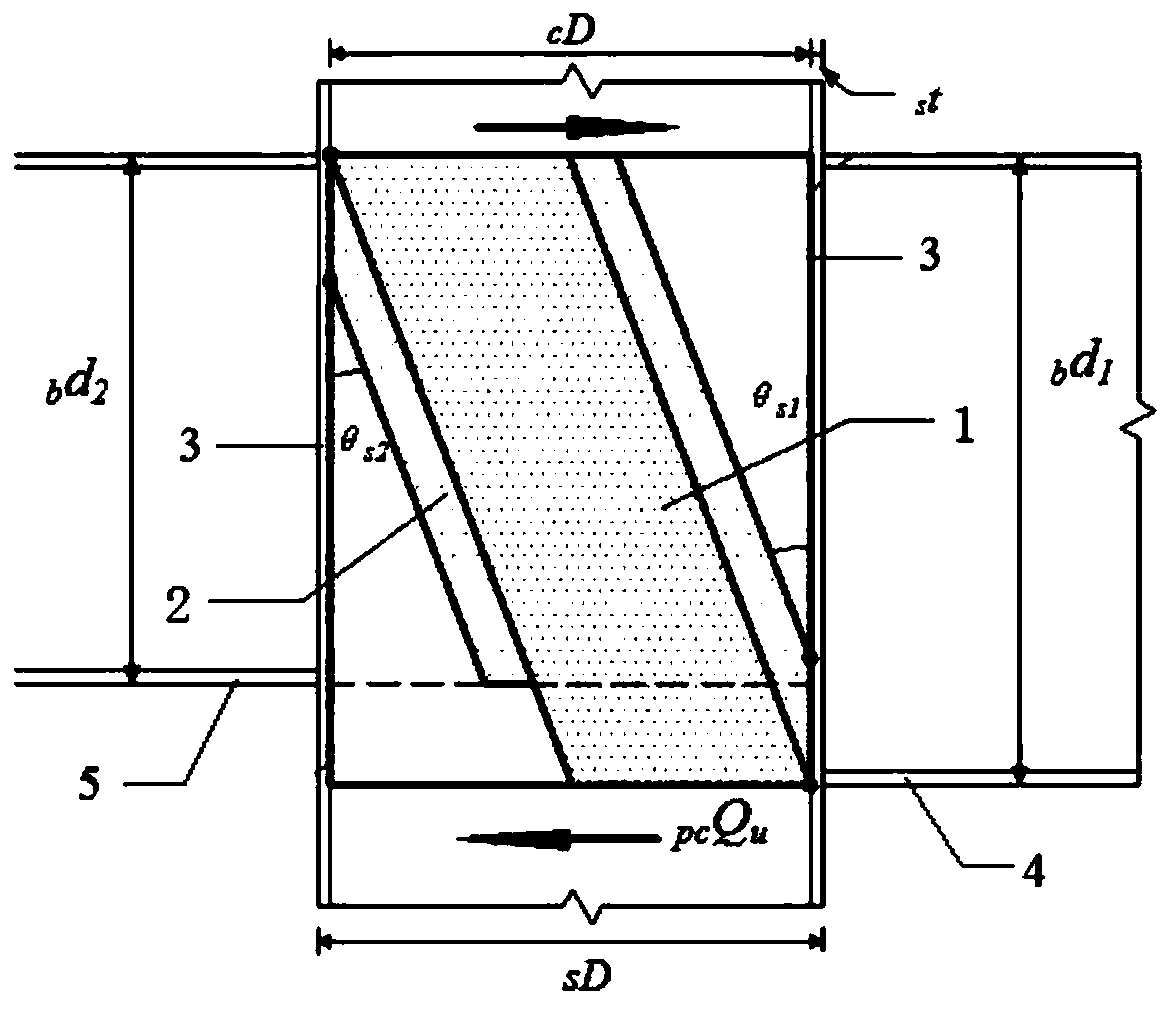

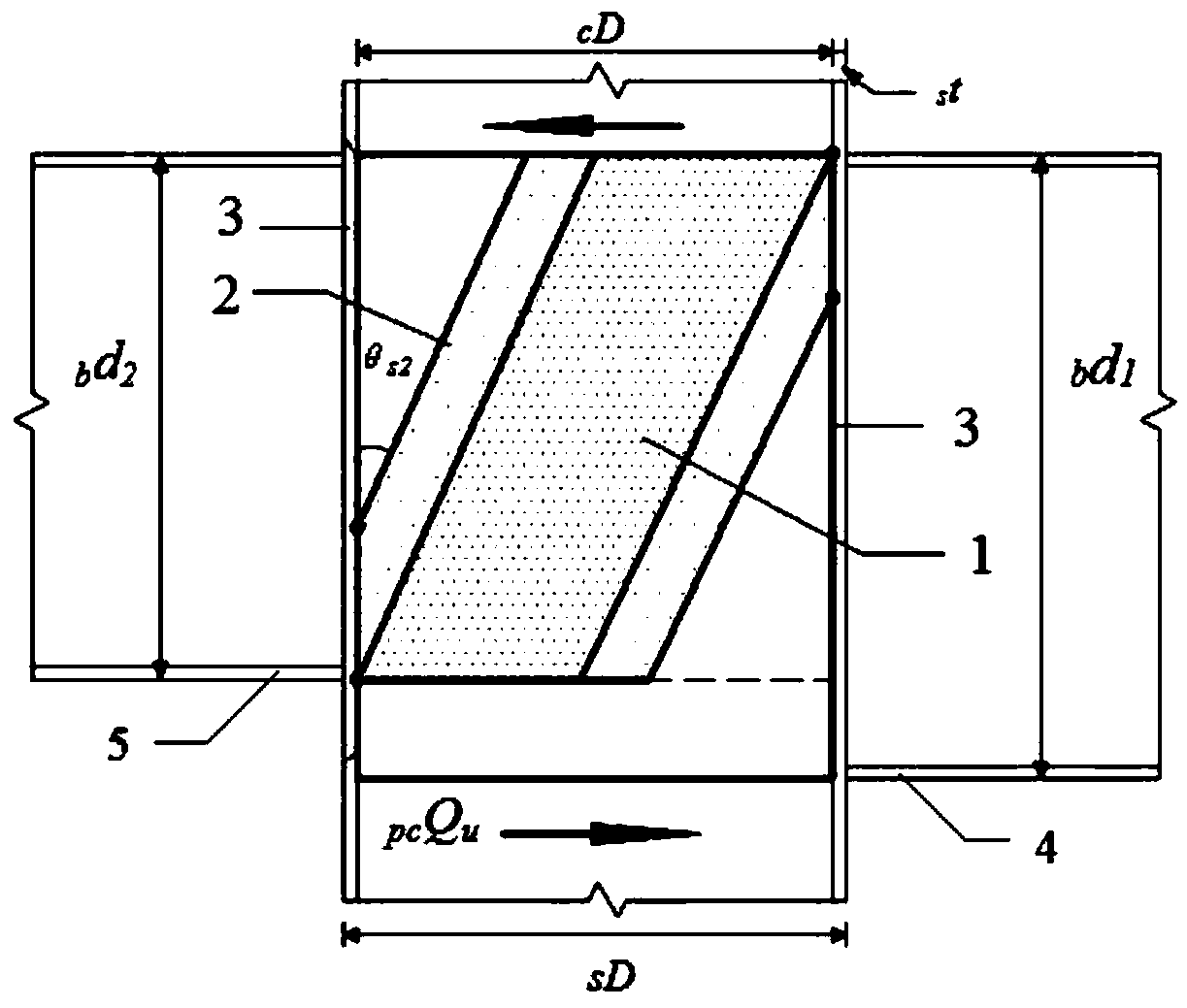

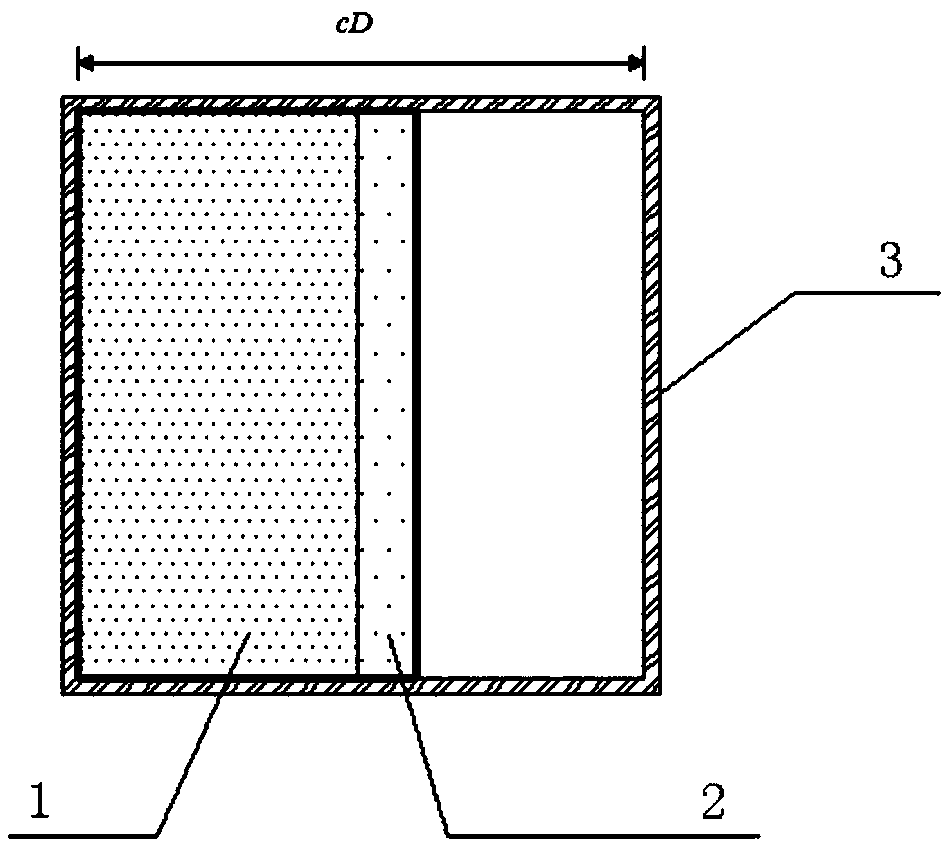

[0073] Such as Figure 1-4 As shown, a certain high and low steel girder square concrete filled steel pipe column joint shear force evaluation method of the present invention comprises the following steps:

[0074] Step 1: Preset the geometric dimensions of the joints of the high and low steel girder square concrete filled steel pipe columns, the type of steel used and the grade of concrete. The size of the steel pipe concrete column is 300×300×13 (unit is mm, the same below), the size of the high beam 4 is 600×200×11×17, the size of the low beam 5 is 550×200×10×16, and the strength of the steel pipe 3 s σ y 350N / mm 2 , Compressive strength of filled concrete ( c σ B ) is 27.5N / mm 2 , the standard value of the compressive strength of the filled concrete f ck 38.5N / mm 2 , steel pipe 3-wall cross-sectional area A s = s D. 2 - c D. 2 =90000-75076=14924, concrete section area A c = c D. 2 =75076, the axial pressure on steel pipe 3 is 3000kN.

[0075] Step 2, known,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com