Nonlinear Ultrasonic Mixing Method for Structural Fatigue Crack Direction Detection

A nonlinear ultrasonic and fatigue cracking technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

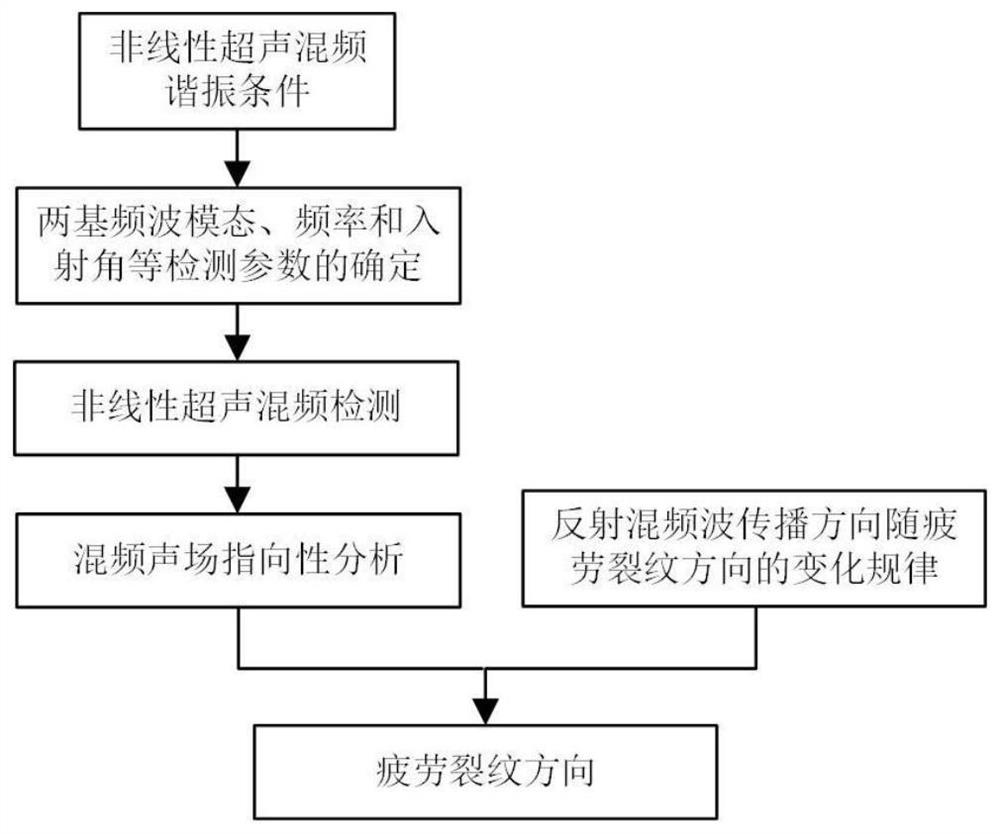

[0063]Combine belowFigure 1~Figure 10 Taking the finite element simulation of shear wave mixing and A0 wave mixing detection as an example, the implementation process of nonlinear ultrasonic mixing method for structural fatigue crack direction detection is explained in detail.

[0064]Using Abaqus commercial finite element analysis software, a two-dimensional finite element model of shear wave mixing and a three-dimensional finite element model of A0 wave mixing with fatigue cracks in two arbitrary directions were established respectively, and numerical simulation of shear wave mixing detection and A0 wave mixing detection were performed. The fatigue crack length in the transverse wave mixing simulation model is 15mm and the directions are 23° and 52°; the fatigue crack length in the A0 wave mixing simulation model is 30mm and the directions are 13° and 35°.

[0065](1) Detection of fatigue crack direction of block structure

[0066]The specific implementation steps of the transverse wave mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com