A method for detecting the content of adsorbed sulfur on the surface of coke

A technology of surface adsorption and detection method, which is applied in the field of chemical analysis, can solve the problem of unable to detect the content of adsorbed sulfur on the surface of coke, and achieve the effect of meeting the requirements of process parameter control, strong operability and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

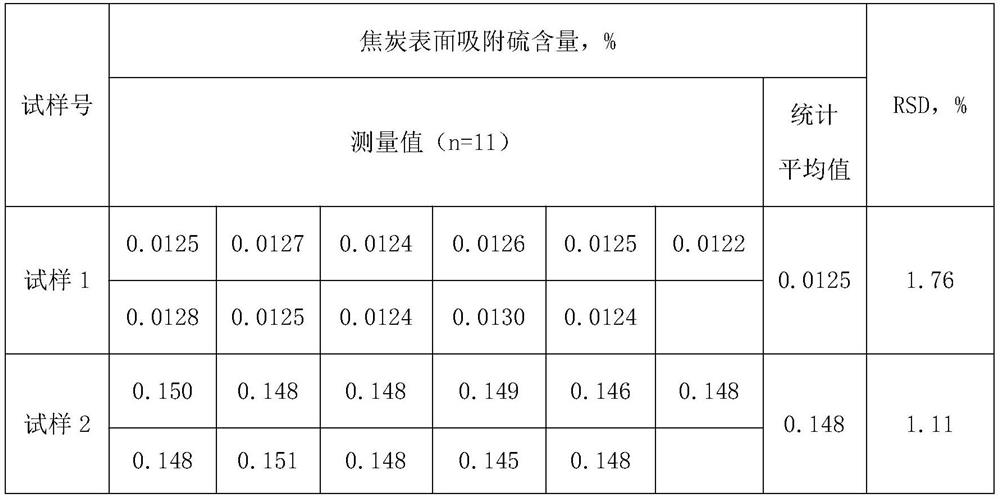

Examples

Embodiment Construction

[0019] A method for detecting the adsorbed sulfur content on the surface of coke, comprising the following steps:

[0020] 1) Prepare a representative coke sample, take 20kg of coke and sieve it, and get 2kg of 30mm block coke as an analysis sample;

[0021] 2) Prepare the solution to be tested, weigh 300g of the analysis sample with a digital display electronic balance, place it in a beaker 1 with a volume of 1000ml, add 500ml of secondary deionized water and 10ml of non-ionized water with a volume ratio of 3:7 to the beaker Immerse the sample in the mixed solution of surfactant OP-10 and Span40, cover the beaker 1 with a watch glass, place the beaker 1 covered with the watch glass in the ultrasonic oscillator for 4 hours, and take out the beaker 1 from the ultrasonic oscillator , use quantitative slow filter paper to filter the solution in beaker 1 to obtain the filtrate, transfer the filtrate to the beaker 2 with a volume of 200ml, and take 10ml of the filtrate from the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com