Bionic cascade phase change energy storage device

A phase-change energy storage and cascade technology, which is applied in the direction of heat exchange equipment, heat exchanger type, heat storage equipment, etc., can solve the problems of limiting the heat storage capacity of the energy storage plate, slow heat transfer, poor thermal conductivity, etc., and achieve melting Effects of increasing time, increasing movement speed, and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A further detailed description is carried out below in conjunction with the description of the accompanying drawings:

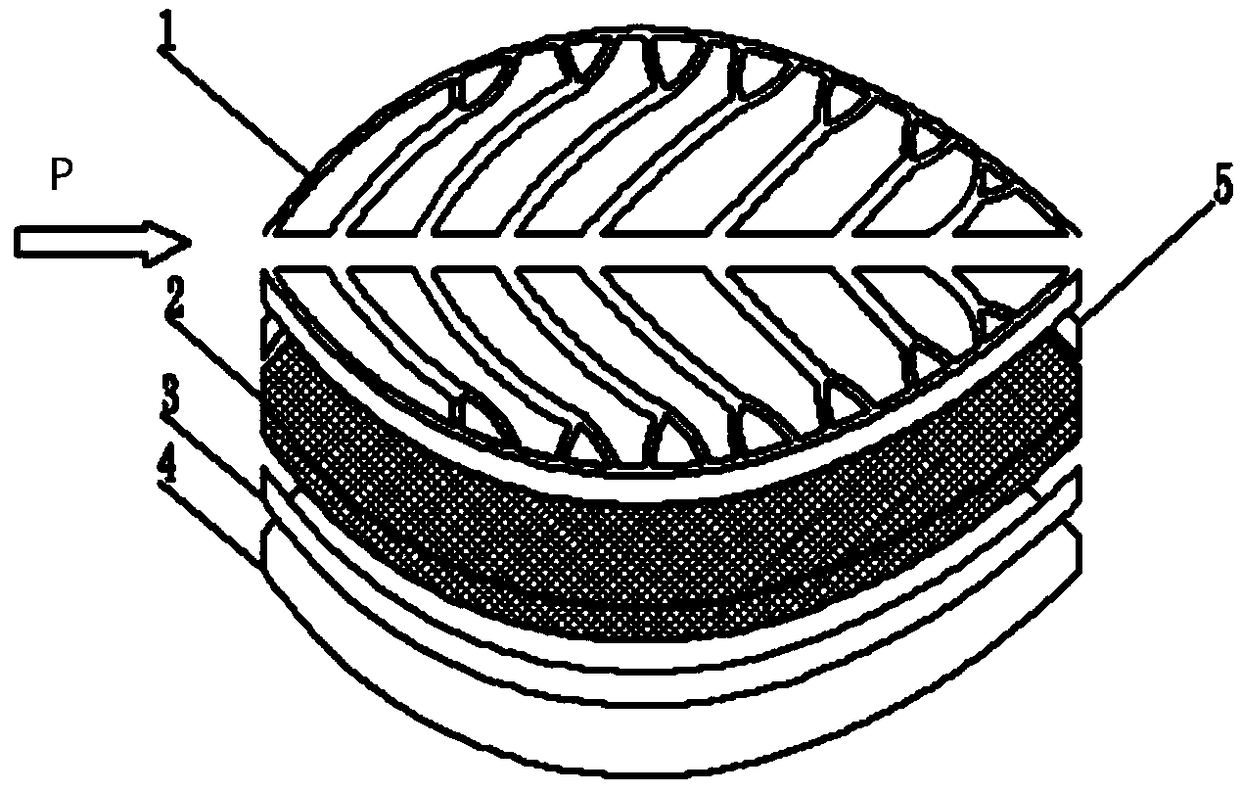

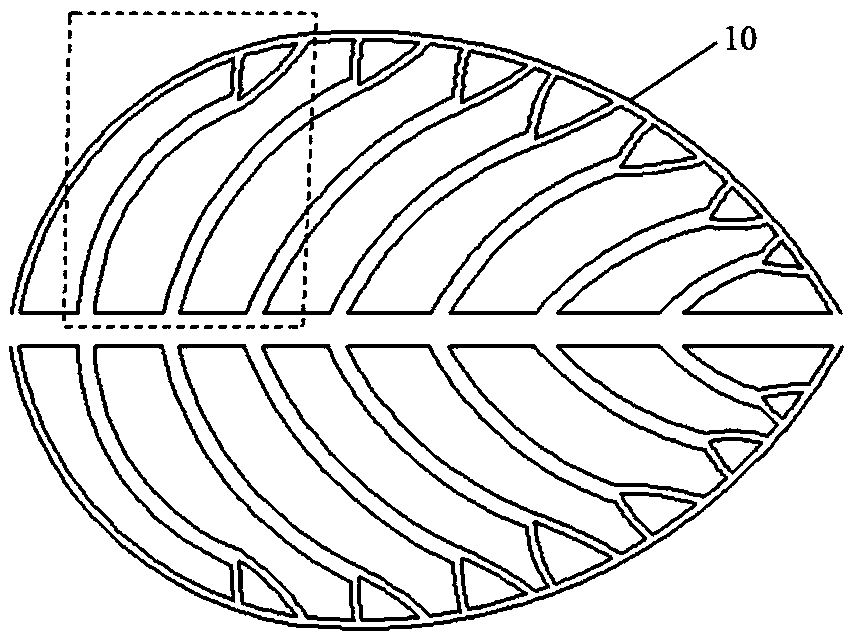

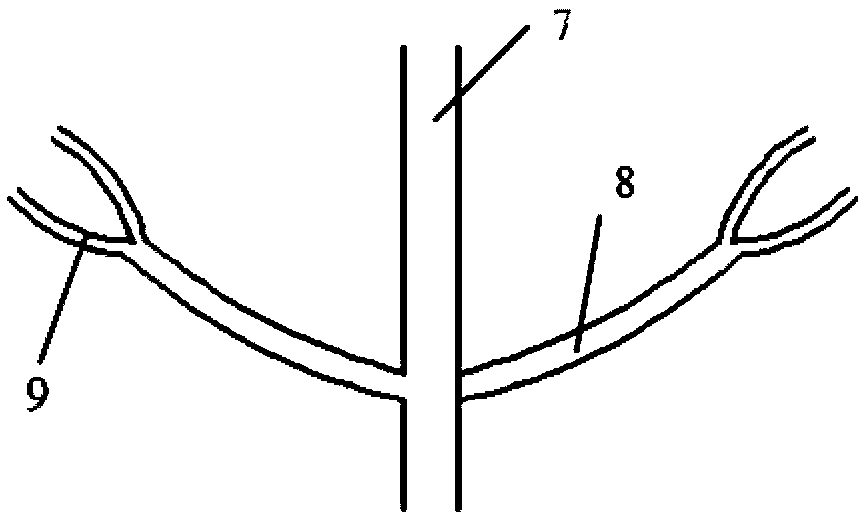

[0029] figure 1 Shown is a three-dimensional structural diagram of a bionic cascade phase change energy storage device with variable porosity optimized perforated frame structure, which is a closed energy storage composed of heat exchange surface 1, lower wall surface 4, rear wall surface 5, front wall surface 3 and perforated frame structure 2 device, the phase change cavity is composed of a metal perforated structure 2 and a phase change material. The heat exchange surface 1 and the lower wall 4 are connected by an annular wall; the pore frame structure in the phase change cavity is composed of sintered foam metal, and the pores filled with phase change materials in the middle are optimized by the porosity algorithm, and the porosity is designed to be high in the middle and low on both sides. Variable porosity structures with intermediate linearly v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com