Pre-embedding free overhanging discharging platform fixing device and fixing method thereof

A technology of unloading platform and fixing device, which is applied in the processing of building materials, construction, building structure, etc., can solve the problem of unable to meet the high-efficiency turnover of materials, and achieve the effect of saving installation time, saving man-hours, and shortening construction man-hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

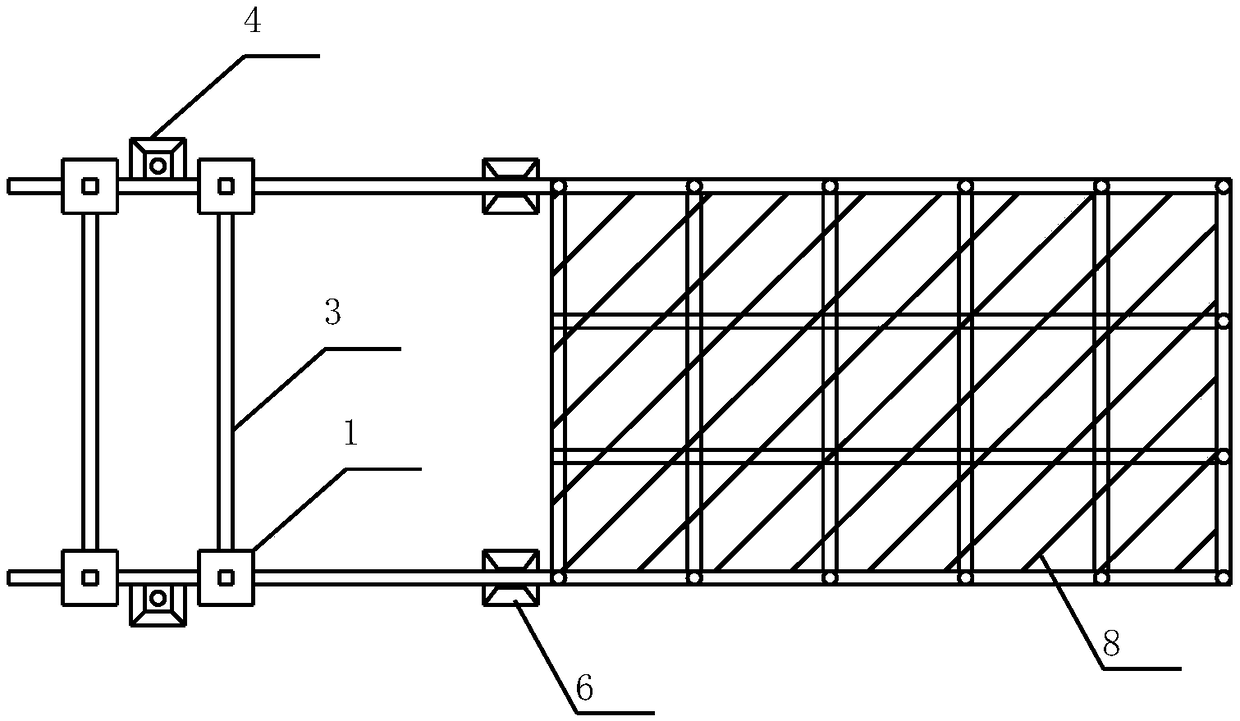

[0029] Combine below figure 1 with figure 2 The structural composition of the non-embedded cantilever unloading platform fixing device of the present invention will be described in detail.

[0030] Please refer to figure 1 with figure 2 , a fixing device for a cantilever unloading platform without pre-embedding, which includes a top-floor fixing piece 1 fixed on the bottom of the upper floor; a longitudinal support rod 2 whose top end is longitudinally connected to the fixing piece 1 and whose bottom end is fixed on the cantilever unloading platform. The tail I-shaped steel 5 of the material platform; the horizontal support 3 is connected to the upper part of the longitudinal support rod 2, and the horizontal support 3 crosses each other to form a well-shaped frame; the adjustable steel support 4 is connected with the tail I-shaped of the cantilevered unloading platform. Steel detachable connection; rotatable support 6, the upper end is fixedly connected with the middle I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com