AssembLing type shear waLL verticaL seam teeth groove type connecting structure

A technology for connecting structures and shear walls, which is applied in the direction of walls, building components, building structures, etc., can solve the problem of low integrity and rigidity of prefabricated shear walls, heavy wet work workload and difficult quality of prefabricated shear walls. Guarantee and other issues, to achieve the effect of avoiding post-cast concrete formwork, improving construction technology, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

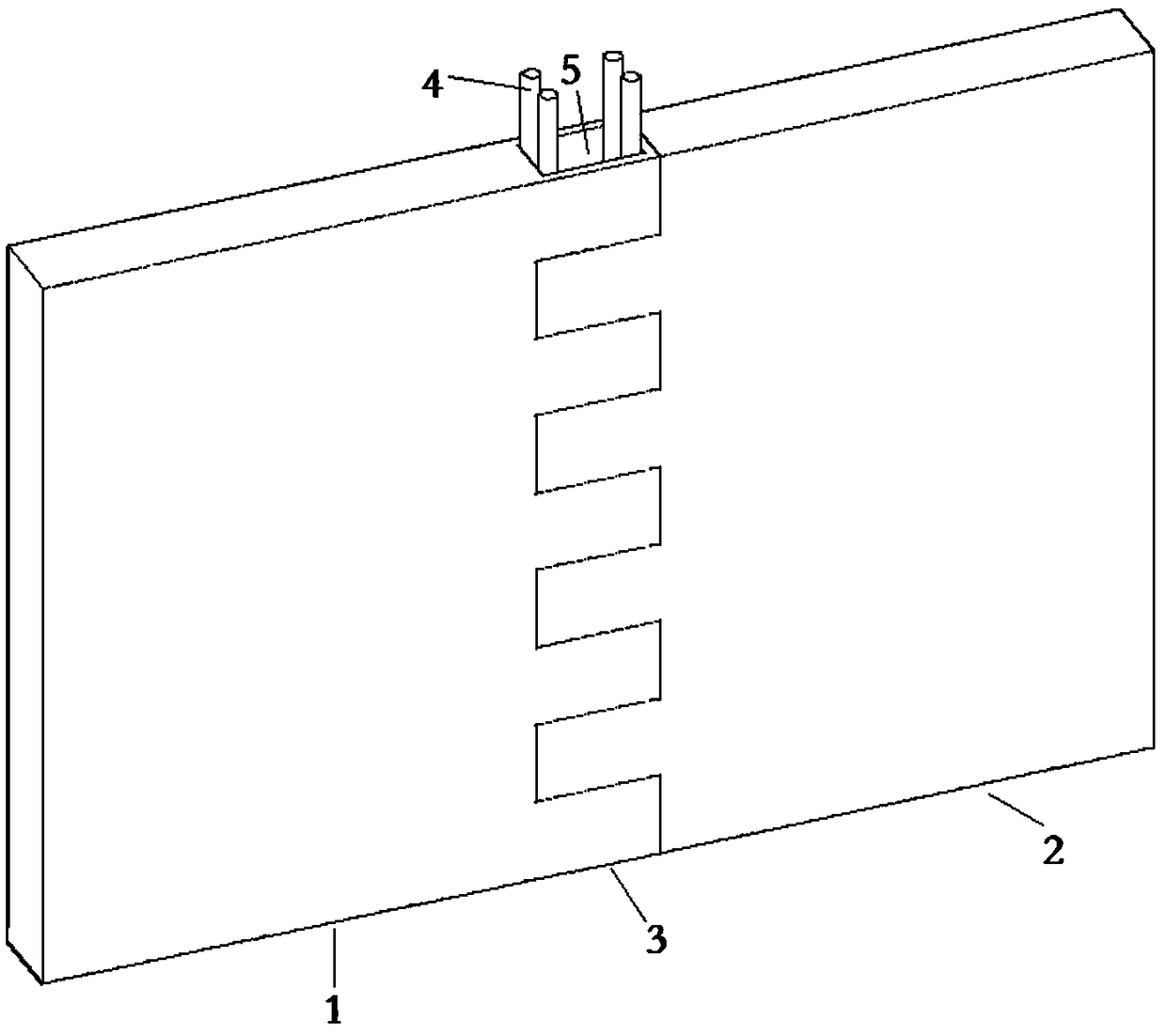

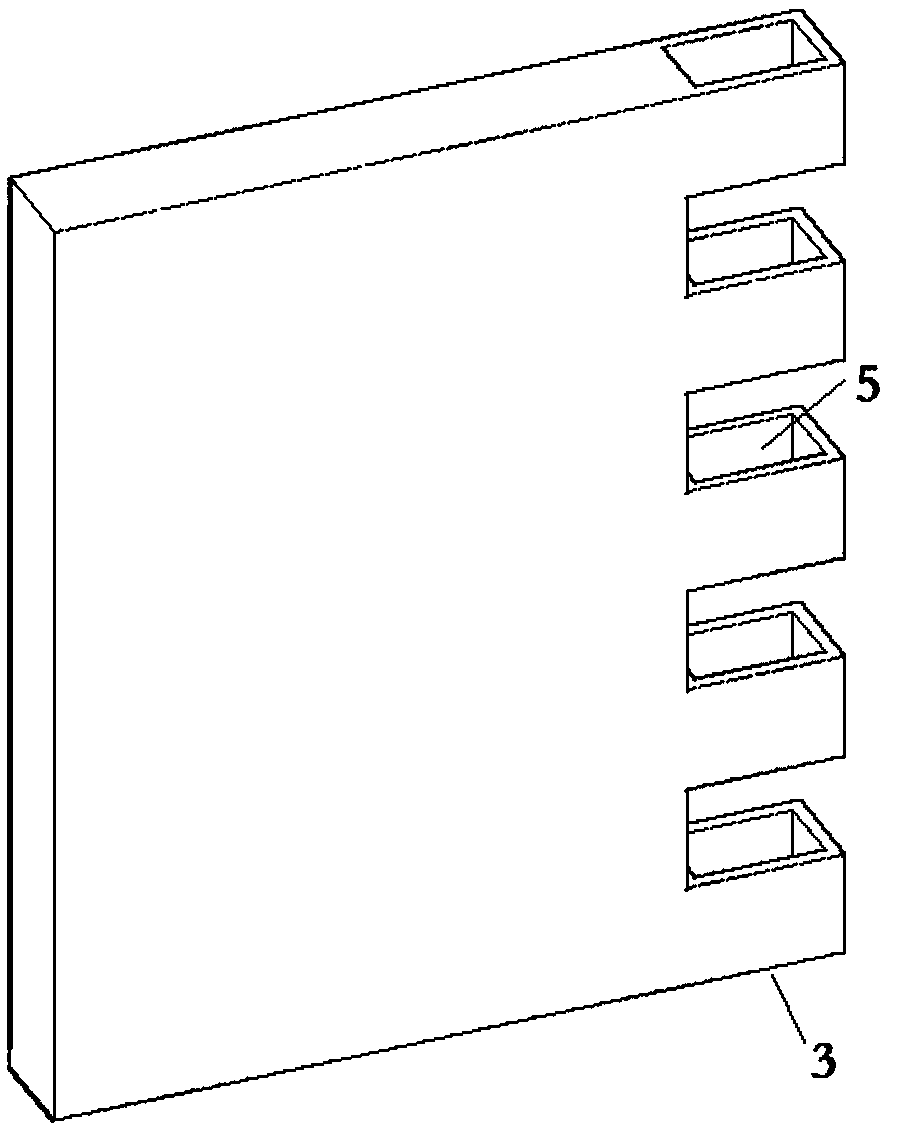

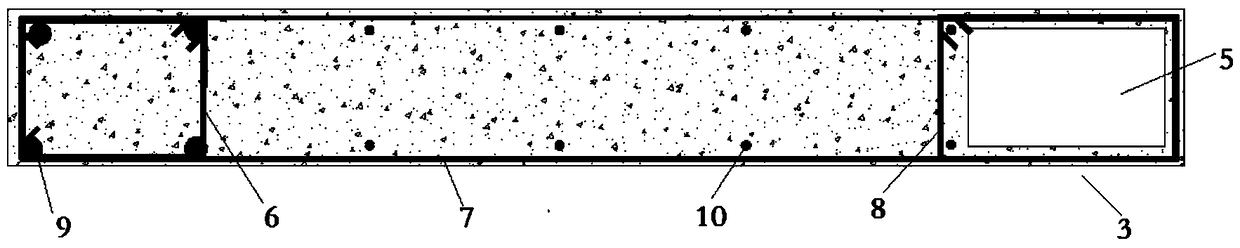

[0023] Such as Figure 1 to Figure 4 A prefabricated shear wall vertical joint alveolar connection structure shown, including the left prefabricated alveolar shear wall 1 and the right prefabricated alveolar shear wall 2, the left prefabricated alveolar One end of the prefabricated alveolar shear wall piece 1 and the right prefabricated alveolar shear wall piece 2 is a flush end, and the other end is a joint end, and the left prefabricated alveolar shear wall piece 1 and the right prefabricated alveolar shear wall The joint ends of the shear wall pieces 2 are provided with reserved slots, and the reserved slots 3 on both sides are engaged with each other, and the protruding teeth of the reserved slots 3 are provided with post-casting holes 5. Concrete is poured in the pouring hole 5, and the post-pouring hole 5 is fixedly connected with the rear longitudinal reinforcement 4 through the concrete, and the rear longitudinal reinforcement 4 runs through all the post-pouring holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com