Expansion plug convenient to install and dismantle and application

A technology for easy installation and expansion plugs, applied in construction, infrastructure engineering, caisson, etc., can solve the problems of construction quality impact, waste of time, cumbersome operation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

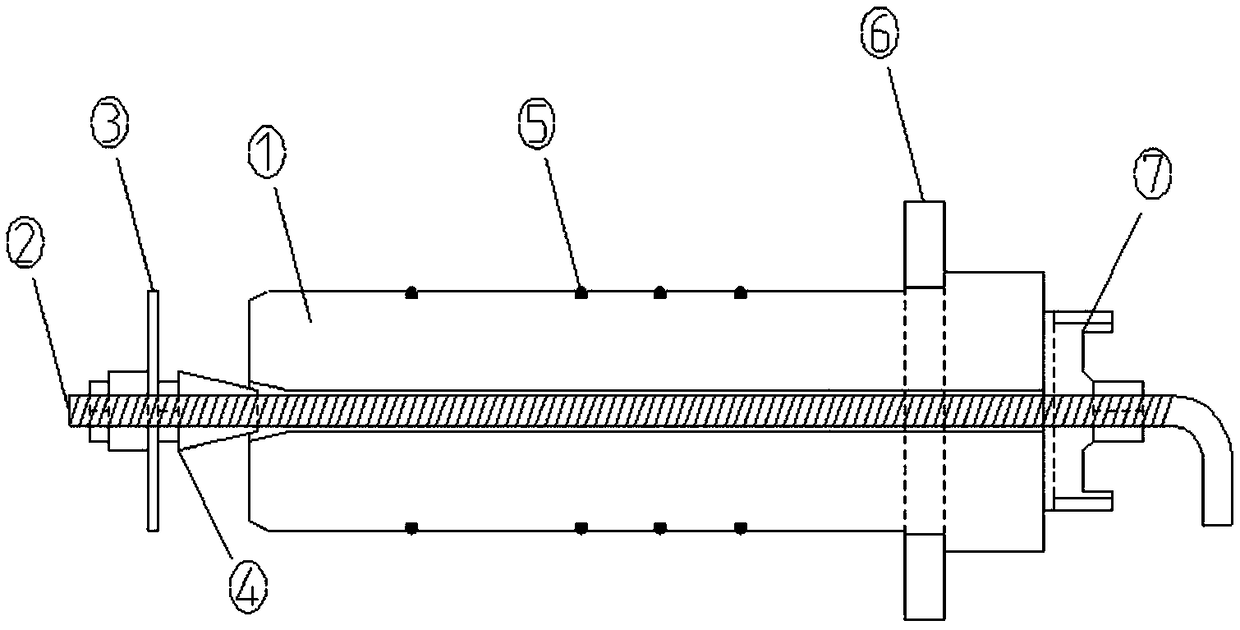

[0019] Such as figure 1 As shown, the expansion plug is easy to install and disassemble. The cylindrical expansion plug body 1 is perforated inside. The front end of the hole is an inverted tapered opening matching the size of the inverted tapered plug body 4. The screw 2 is inserted through the expansion plug body 1. , the front section of the lead screw 2 is installed with an inverted tapered plug body 4, the rear part of the expansion plug body 1 is connected to a baffle plate 6 whose diameter is larger than that of the expansion plug body 1, the inverted tapered plug body 4 and the baffle plate 6 are connected through the lead screw 2, and the expansion The rear end of the plug body 1 is connected with a compass 7 with a bayonet, and the rear end of the lead screw 2 passes through the compass 7 .

[0020] A groove is provided on the main body 1 of the expansion plug, and a water-stop rubber ring 5 is sleeved in the groove.

[0021] The water-stop rubber rings 5 are in f...

Embodiment 2

[0026] The application of the expansion plug convenient for installation and disassembly described in Example 1, the expansion plug is applied to the plugging of underwater holes, and the specific application method includes the following steps:

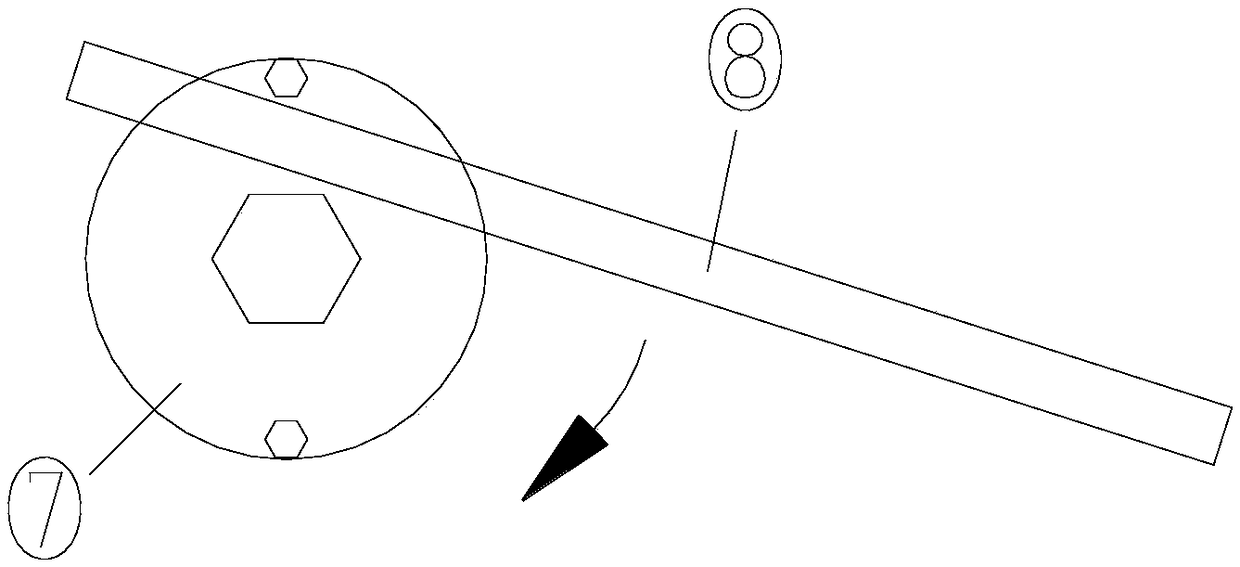

[0027] S1. After processing various materials, assemble them. When sealing the hole, insert the front end of the expansion plug into the hole, such as figure 2 As shown, use a round steel 8 with a length of 30 cm and a diameter of 1.5 cm, clamp it at the bayonet of the compass 7, rotate it clockwise, and tighten the screw 2, so that the inverted tapered plug body 4 faces the expansion plug body 1 hole Move inside to expand the diameter of the rear section of the main body 1 of the expansion plug to achieve the purpose of sealing; at the same time, the components can be processed and manufactured according to the size of the hole, so as to be suitable for the sealing of holes of different sizes;

[0028] S2. When removing the expansi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com