Cotton yarn production process

A production process, cotton yarn technology, applied in the field of textile technology, can solve problems such as poor yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

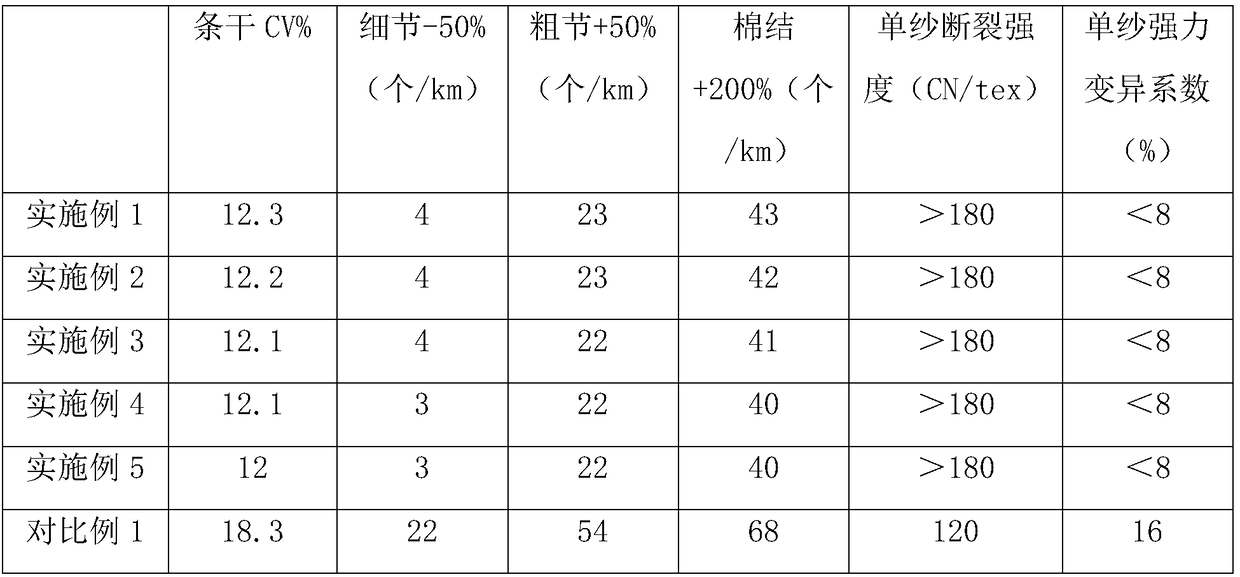

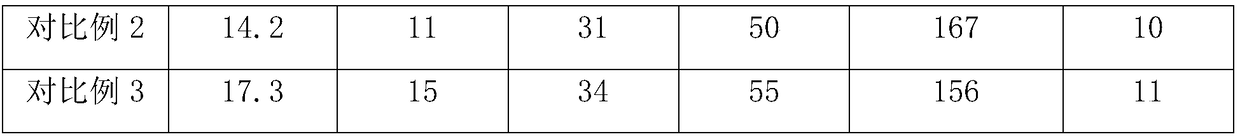

Examples

Embodiment 1

[0030] A cotton yarn production process, using cotton as raw material, including cleaning, carding, drawing, roving, spun yarn, winding and packaging processes, the cleaning process includes the steps of picking cotton, opening cotton, cleaning cotton, mixing cotton and rolling , before catching cotton, spray 0.002 times the weight of antistatic agent and 0.006 times the weight of water into the cotton, ultrasonic vibration treatment, so that the cotton can fully absorb moisture and activate the surface of cotton fibers, and use a reciprocating catching cotton machine when catching cotton; It uses a roving frame to make a part of the cooked sliver obtained in the drawing process into a roving intermediate through drafting and twisting, and then feeds the remaining cooked sliver and the roving intermediate into the roving frame to make a roving, and winds the roving into a package; the spinning method of the spinning process adopts siro compact spinning.

[0031] Wherein, the a...

Embodiment 2

[0046] A cotton yarn production process, using cotton as raw material, including cleaning, carding, drawing, roving, spun yarn, winding and packaging processes, the cleaning process includes the steps of picking cotton, opening cotton, cleaning cotton, mixing cotton and rolling , before catching cotton, spray 0.003 times the weight of antistatic agent and 0.007 times the weight of water into the cotton, ultrasonic vibration treatment, so that the cotton can fully absorb moisture and activate the surface of cotton fibers, and use a reciprocating catching cotton machine when catching cotton; It uses a roving frame to make a part of the cooked sliver obtained in the drawing process into a roving intermediate through drafting and twisting, and then feeds the remaining cooked sliver and the roving intermediate into the roving frame to make a roving, and winds the roving into a package; the spinning method of the spinning process adopts siro compact spinning.

[0047] Among them, th...

Embodiment 3

[0062] A cotton yarn production process, using cotton as raw material, including cleaning, carding, drawing, roving, spun yarn, winding and packaging processes, the cleaning process includes the steps of picking cotton, opening cotton, cleaning cotton, mixing cotton and rolling , before catching cotton, spray 0.002 times the weight of antistatic agent and 0.007 times the weight of water into the cotton, ultrasonic vibration treatment, make the cotton fully absorb moisture and activate the surface of cotton fibers, use reciprocating catching cotton machine when catching cotton; roving process It uses a roving frame to make a part of the cooked sliver obtained in the drawing process into a roving intermediate through drafting and twisting, and then feeds the remaining cooked sliver and the roving intermediate into the roving frame to make a roving, and winds the roving into a package; the spinning method of the spinning process adopts siro compact spinning.

[0063] Wherein, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com