Automatic exhaust device of biogas tank

An automatic exhaust and exhaust device technology, applied in biochemical cleaning devices, enzymology/microbiology devices, gas production bioreactors, etc., can solve the problems of biogas tank damage, burst, high pressure, etc., to achieve gas production The effect of high production rate and prevention of excessive pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

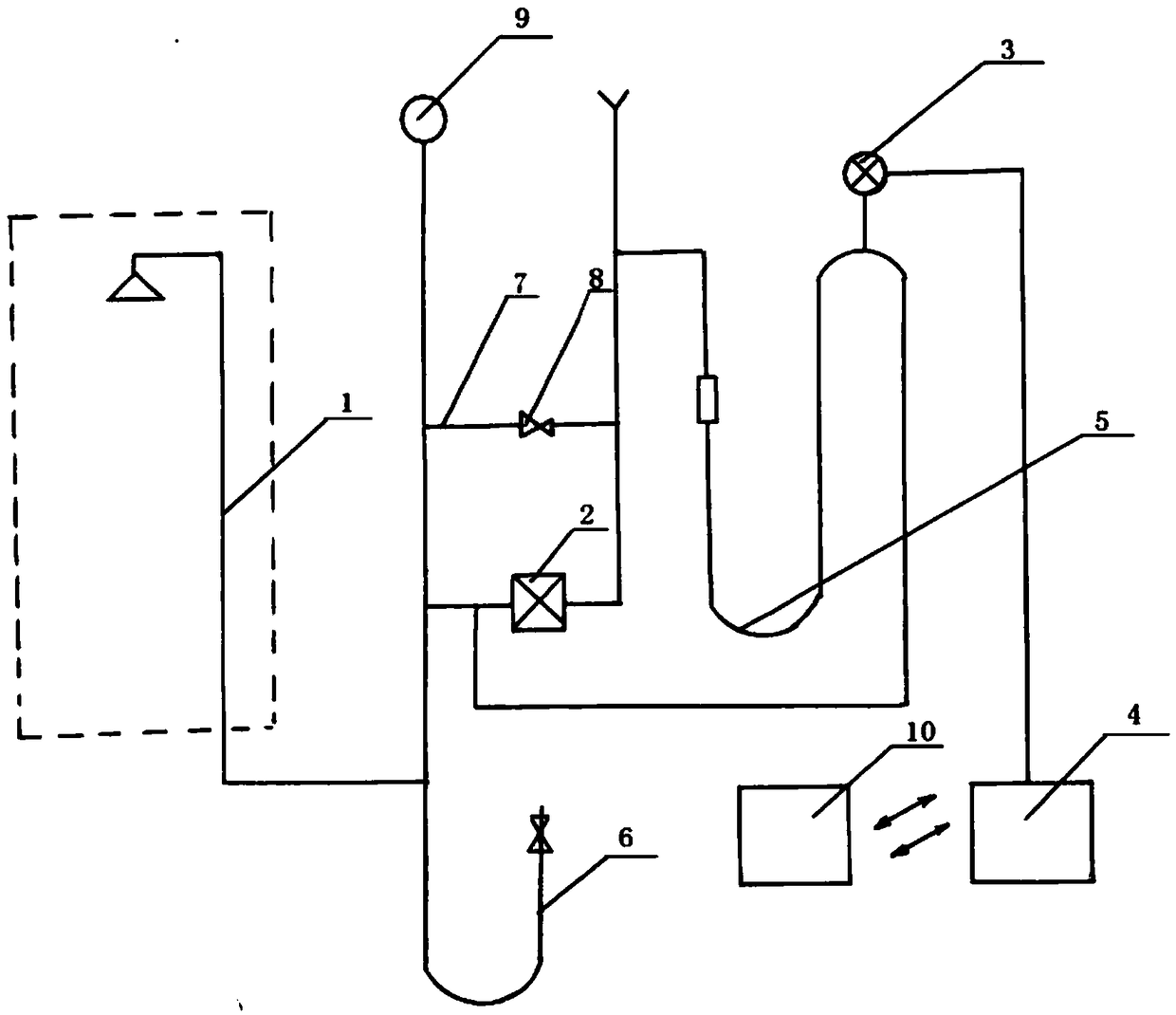

[0011] The device of the present invention comprises an exhaust pipe 1, an explosion-proof solenoid valve 2, a pressure sensor 3, a processing and controller 4, and a reverse water elbow 5. A U-shaped drain pipe 6 is connected to the air pipe 1, and the front end of the reverse water elbow 5 is connected to the exhaust pipe 1 between the explosion-proof solenoid valve 2 and the U-shaped drain pipe 6, and the rear end is connected to the right end of the exhaust pipe 1 , the exhaust pipe 1 is a pipe with vertical left and right ends and a horizontal pipe in the middle section, and the middle section is at the bottom. The explosion-proof solenoid valve 2 is installed in the middle section. In the middle section of the pipe 1, the pressure sensor 3 is connected to the signal input end of the processing and controller 4, the control end of the processing and controller 4 is connected to the explosion-proof solenoid valve 2, and the right port of the exhaust pipe 1 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com