High and low temperature-resistant conductive organosilane pressure-sensitive adhesive and preparation method and application thereof

A silicone pressure sensitive adhesive, high and low temperature resistant technology, applied in the direction of conductive adhesives, pressure sensitive films/sheets, adhesives, etc. Poor performance and other problems, to achieve the effect of wide temperature range, lower installation cost, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

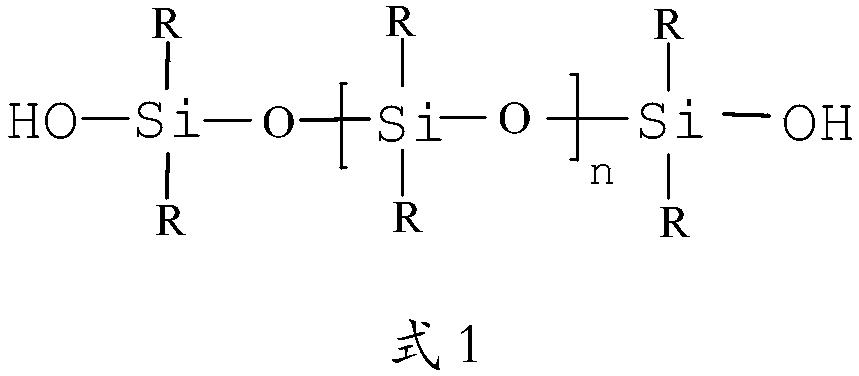

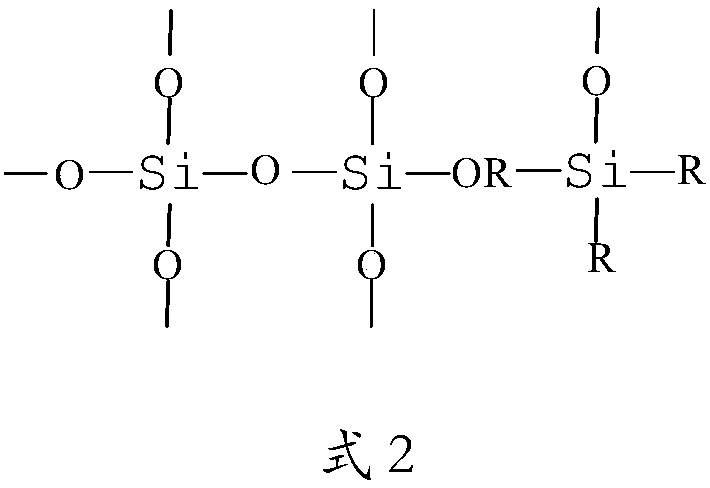

Method used

Image

Examples

preparation example Construction

[0058] MQ resin was prepared as follows:

[0059] Step (1) In the round bottom flask (A), add the formulated amount of hexamethyldisiloxane, methylvinyldisiloxane and isopropanol, stir and raise the temperature to 65-70°C within 20 minutes.

[0060] Step (2) Add dilute sulfuric acid and sodium silicate to a flask (B) equipped with a condensing reflux pipe, a stirrer, a nitrogen protection device, a constant pressure funnel, and an air bath temperature control heating device, start stirring, and heat up to 85 Preheat at ~90°C for 15 minutes until the sodium silicate is completely dissolved.

[0061] Step (3) move the mixed solution in the flask (A) into the dropping funnel, add dropwise in the flask (B), control the drop-in time of the mixture of hexamethyldisiloxane and methylvinyldisiloxane at Between 12 and 15 minutes, maintain the reaction temperature at 115 to 120°C, and react for 1 hour.

[0062] Step (4) cool down to room temperature, extract, distill, and dry, and the...

Embodiment 1~3

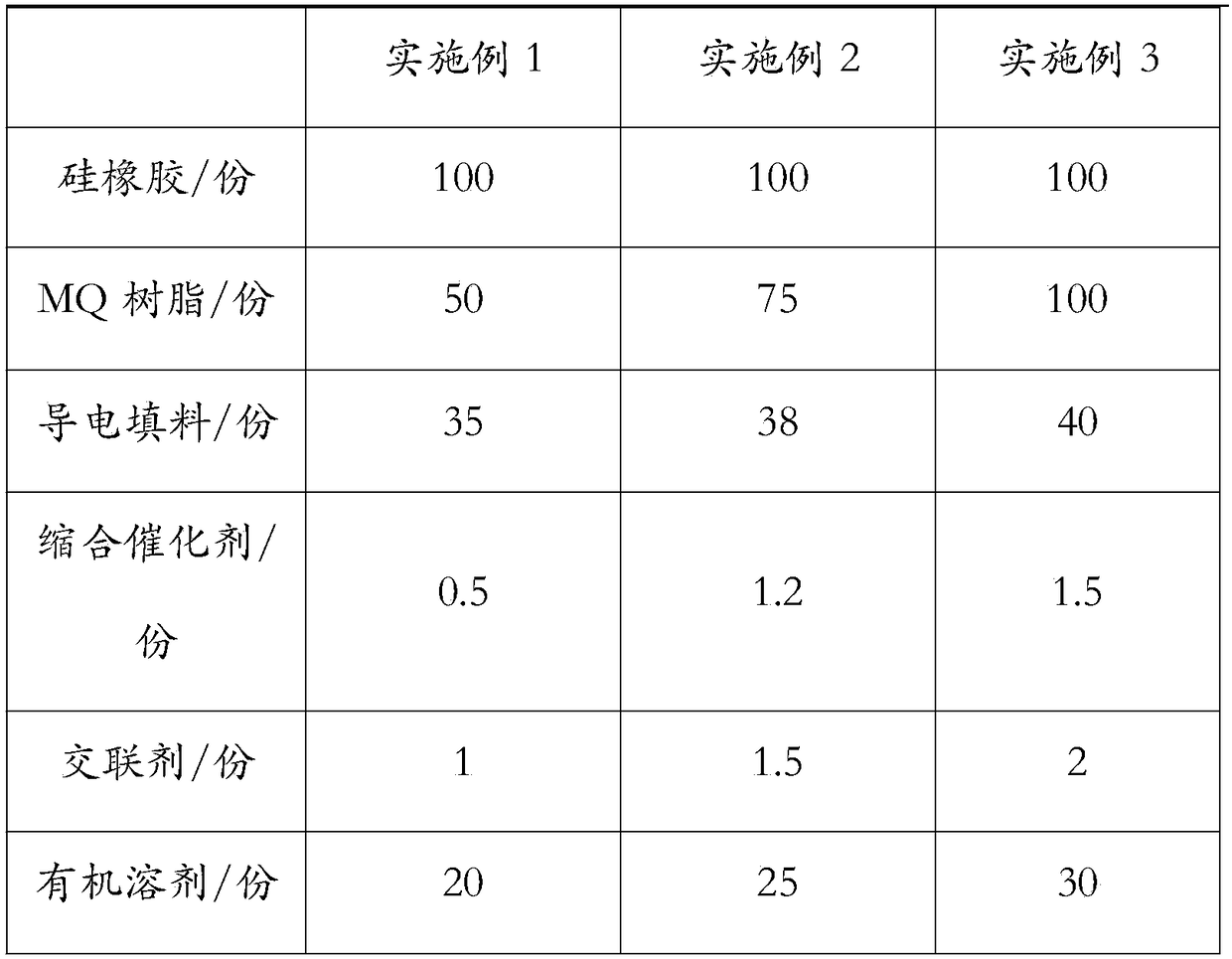

[0071] The raw materials were weighed according to the proportions in Table 1, and prepared according to the steps in Example 1. The difference is that the added raw material proportions are different, and the products are prepared. See Table 1 for details:

[0072] Table 1: Raw Material Proportion Table of Embodiments 1 to 3

[0073]

[0074] In Table 1, the silicone rubber is a composition of methyl silicone rubber and phenyl silicone rubber, the weight ratio of methyl silicone rubber and phenyl silicone rubber is 1:1, and the molar fraction of silicone rubber is 12%. Viscosity 6x10 3 ~1.2x10 4 mPa·s), the crosslinking agent is 2,4-benzoyl peroxide, the condensation catalyst is dibutyltin dilaurate, the organic solvent is toluene, and the conductive filler is nickel-plated carbon fiber.

[0075] MQ resin is prepared from the following components in parts by weight: 4 parts of isopropanol, 5.5 parts of dilute sulfuric acid, 1.5 parts of hexamethyldisiloxane, 1.5 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com