Prying-mounting equipment for treating mine wastewater and treating method

A treatment method and mine technology, applied in filtration treatment, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as failure to meet underground safety requirements, and achieve the effect of facilitating on-site construction and installation, demolition and relocation, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

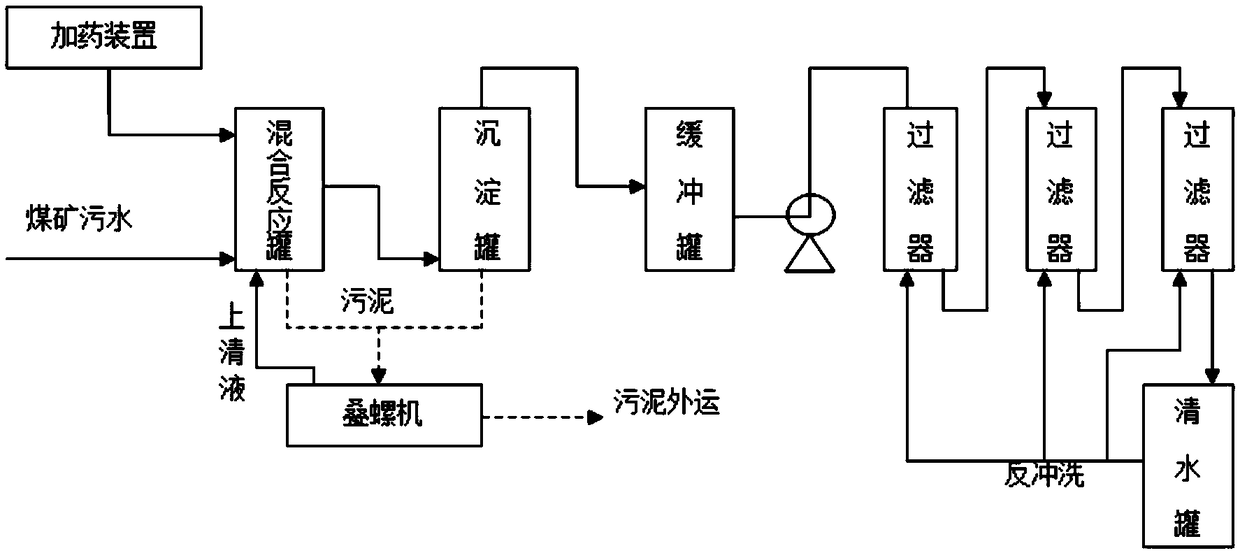

Method used

Image

Examples

Embodiment 1

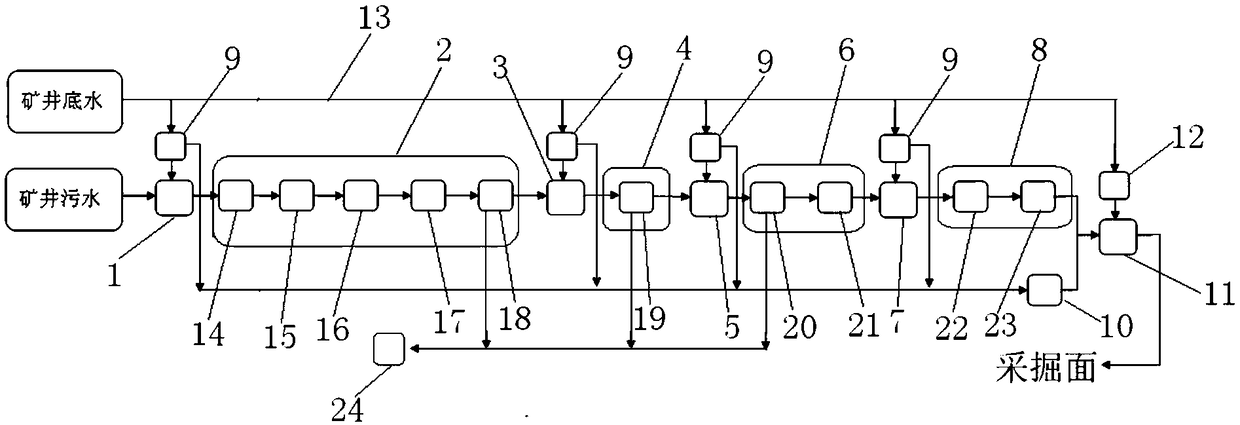

[0044] A drain hole is drilled in the coal seam, and the bottom water of the coal seam with a pressure of 1.5Mpa to 3.0Mpa is collected through the bottom water pipeline 13 and transported to the first water turbine 9 and the second water turbine 12 to drive the first lift pump 1 and the second water turbine respectively. Lift pump 3, third lift pump 5, fourth lift pump 7 and fifth lift pump 11; mine sewage with turbidity of 80-300 (NTU) and COD of 60mg / L-90mg / L passes through the first lift pump 1 Sequentially enter the first dosing device 14 and the first pipeline mixer 15 equipped with treatment agent A, and the water from the first pipeline mixer 15 enters the second pipeline mixer 17 through the second dosing device 16 equipped with treatment agent B , and mixed with the treatment agent B in the second pipeline mixer 17, after mixing, it enters the primary hydrocyclone 18 for centrifugal sedimentation, and the outlet water of the primary hydrocyclone 18 enters the secondar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com