A retractable sliding table device controlled by plc closed loop

A closed-loop control and scalability technology, applied in the field of diffusion furnaces, can solve problems such as occupying a lot of site space, threatening staff, equipment raw materials and product safety, and large structure size of diffusion furnaces, preventing damage, reducing the overall size of the equipment, The effect of saving on-site space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

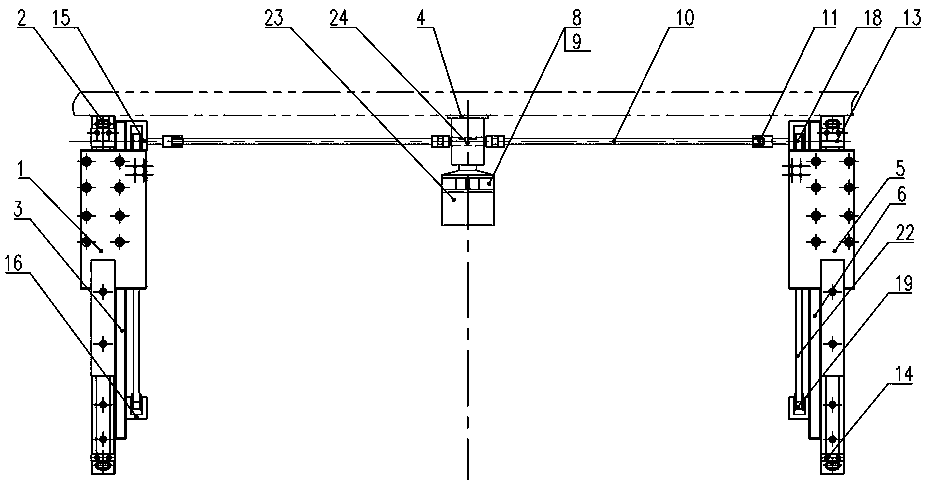

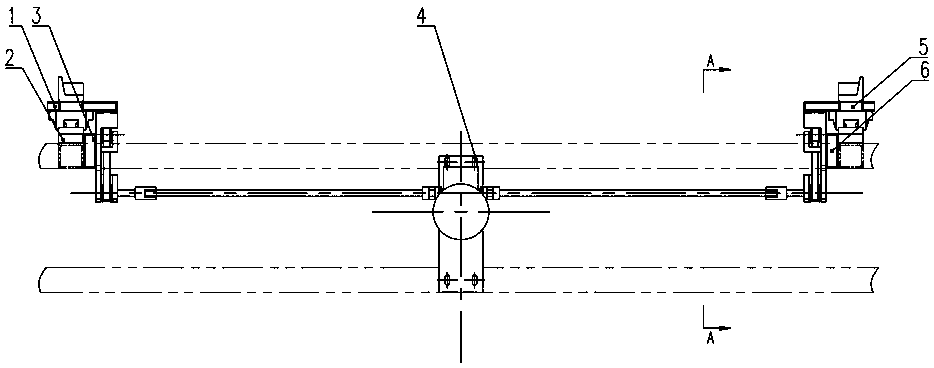

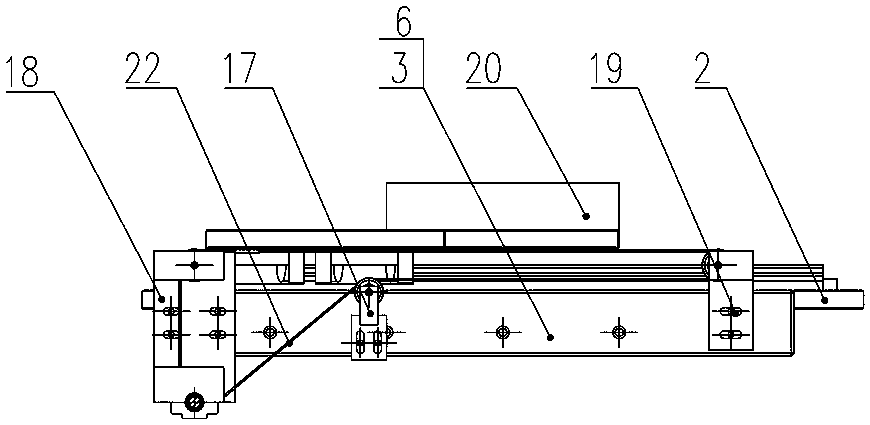

[0024] Such as Figure 1 ~ Figure 3 Shown, the retractable sliding table device controlled by PLC closed-loop of the present invention comprises:

[0025] The sliding parts include two linear guide rails arranged along the movement direction of the quartz boat seat 20, which are respectively located on the guide rail mounting plates 2 on the left and right sides; the slider (not shown) used to move the quartz boat seat 20 is Sliding on the linear guide rail and driven by the driving part;

[0026] Drive components include a stepper motor 23 and a speed reducer 24, and the motor shaft 9 of the stepper motor 23 is connected with the speed reducer 24;

[0027] Transmission parts, including left driving wheel assembly 15, right driving wheel assembly 18, and two connecting rods 10, one end of one connecting rod 10 is connected with step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com